Madaidaiciyar madaidaiciya

EPS toshe gabatarwa inji

A kwance toshe na'ura ta fara daga China, ba ya bukatar babban bita sosai. Yanzu muna ƙara tsarin daidaita ta atomatik da tsarin nauyi, don samun ƙarin atomatik kuma yana taimakawa don ceton kuɗin aikin.

EPS toshe na'ura siffofin EPS beads tare da toshe. Akwai bin jerin abubuwa da yawa don samar da toshe EPS:

• Cika kayan kwalliya na EPS cikin injin cajin na EPS ɗin da yake ciyar da na'urar.

• Zuba lantarki mai hawa ta tururi

• Cool the beads a cikin m.

• fitar da abin toshe da aka gama daga kogon lafiya.

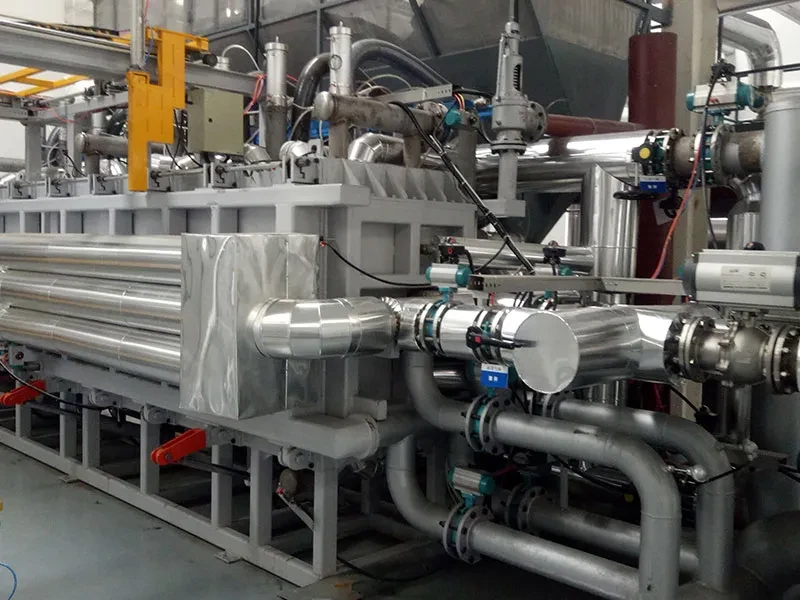

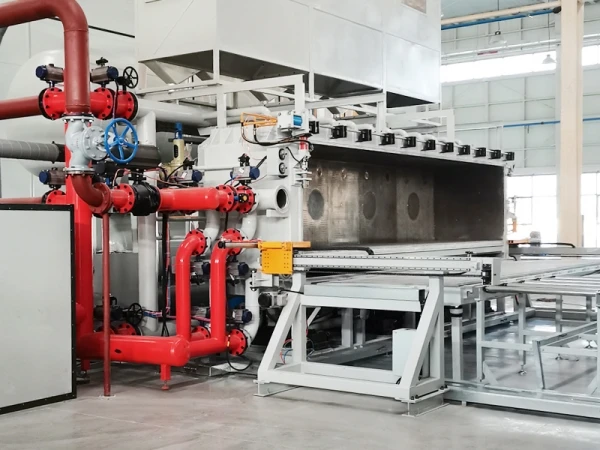

A. EPS ta toshe jikin injin

• WANNAN WANNAN POLYSTRETRENE TABARIN MULKIN SIFFOFI an tsara shi a cikin Nau'in kwance tare da budewar ɗaya kaɗai, don tabbatar da ƙarancin ƙwayar cuta a lokacin sanyaya.

• Jikin an welded don ginin. Ganuwar ciki sune farantin aluminum tare da ramuka, 5mm kauri.

• An yi injin tare da gyara ganuwar, gwargwadon bukatarmu zamu iya bayar da ganuwar.

• Za a kula da ingancin musanyayyiyar fashin baya ta hanyar firam ɗin coam matsa lamba.

• EPS rufe in inji (Aluminum Silamicirer) Zabi ne.

B. Cika silo don toshe mold

Cika sillo yana kan saman EPS toshe injin moldi, an sarrafa matakin kayan aiki ta hanyar na'urori masu auna ta atomatik (zaɓi). Tsarin zai dakatar da injin lokacin da babu isasshen kayan da ake samu a cikin silo.

C. Steaming Tsarin

A cikin kowane tsari matakai yana da matsin lamba mai tururi tare da babban tururi mai kaifi da tsarin tururi mai sarrafa babuta a kowane gefe. Sau biyu hayewa fasahar dilles wanda aka tsara a cikin shirin. Steam ya shiga cikin injin tare daga manyan bangarorin 2 da kuma fitsari daga 4 kananan bangarori yayin dumama na farko.

D. Control Panel

Babban majalisar ministocin, tare da kulle tsaro, sanye take da allon Delta / Siemens taɓawa da PLC.

E. BICE BICK EXTURing naúrar

Yayin aiwatar da tsarin tsarin tsari gaba daya, ƙofar gaban yana buɗewa da hydraulic driven exject za su fitar da EPS na gaba zuwa ƙofar. Bayan haka sai masu silsi guda biyu a saman za su tura toshe zuwa sashin da suke so, bayan da ake so na gefe, to, tlter za ta kasance da toshe daga kwance.

Tsarin F.

Contenter tank co. 1.5 m3 tare da ruwa spraying da sieving raka'a - mutum-bocke tank ca. 10m3. Kwakwalwa biyu (11kW ga kowane) amfani da injin. Tare da taimakon injin, yana taimakawa rage lokacin juyin Turai da abun ciki na ruwa.

EPS toshe ƙayyadaddun injin

Model: SPB (2000/3000/4000/5000/6000) wz

• Ya dace da tsawon EPS: 2000-6000mm

• Ya dace da EPS Tubshe Daidaitar: 1000-1200mm

• Ya dace da kauri na lps: 1000-1200mm

• 12-15 Tubalan / awa @ density 15kg / m3

EPS toshe kayan aikin

• Takaddun A

• fasalolin aminci da yawa

• Za a iya zaɓar yanayin aiki guda biyu: Mataki ko Auto

• naúrar nauyi, tiller da fita tare da isar da fulawa ba na tilas bane

• homogenous toshe yawan (+/- 3%)

Orancin yawan kuzari da kuma fitarwa

• atomatik tsarin yin tsari, nauyi da tsarin tlter ba na tilas bane

• EPS katange tsarin isar da atomatik ba na tilas bane.

Haske na injin: mold jikin Rall5012 Blue + Pipping tsarin Ral3001 Red

EPS cajin tsarin

Ana sarrafa tsarin isar da toshe ta taɓa allon turawa & PLC, na'urori masu mahimmanci, motoci da sarƙoƙi da sarƙoƙi. Ana samun tsarin bushewar atomatik. Yana aiki tsakanin injin EPS da kuma ci gaba da yankan yankan shuka don ƙara ƙarfin atomatik, don rage karfin aikin aiki da gajeriyar lokacin bushewa. Yayinda layi daya ya cika, tsarin zai tsaya don ciyar da wannan layin kuma yana canzawa ta atomatik don ciyar da wani layi. Yayinda layi daya babu komai, tsarin zai daina fitar da wannan layin kuma ya canza don fitar da wani layi.

EPS toshe mahimman kayan molmin

• Taɓawa Allon + Plc: Delta / China

• An kashe matsin lamba: Yayana/ China

• Wutar lantarki: Schneid / Faransa

• faranti na aluminum: 2a12 / china

• Buga mai ban sha'awa: bawul na AbC / Singapore

• bawul din ball: ABC bawul / Singapore

• Bawul na kusurwa: ESG / China

• sassan pnumatic: Airtec / China

• Motocin wuri: Yulong / China

WHOMER PHOTOR: Autonics / Korea