Mold e feto-fetohang ea li-eps tsa boea

Mold e feto-fetoha o feto-fetoha oa mochini oa li-eps tsa mold

Ho bonolo ho fumana boholo bo fapaneng ho li-eps tse fapaneng ka theknoloji e lekantsoeng e nang le boithati. Haholo-holo bakeng sa itloageng ea EPS Sallwich ea EPS, li-blos tsa EPS li ka boloka litšila tse ngata tsa mafura. Re na le lerako le ka tlase ho lerako le potileng lerako le lekaneng le bophara ba lebota le sirelletsang bakeng sa khetho.

Mochine oa li-eps tsa li-eps tsa li-eps tsa ho fofa ke ho theha lintlha tse phahameng hammoho le ho kopana le litlhokahalo tse fapaneng. Bong ba li-eps baps ba ka latela tatellano ea likarolo:

• Tlatsa mochini oa li-eps tsa li-eps tse thibetsoeng ka lieta tse atolositsoeng

• Ho futhumatsa eps block hlobo ke mouoane ke mouoane

• Roala lieta tse ke keng tsa hola ka sistimi ea moea kapa eps vacuum.

• Hlahisa block e felileng ho tsoa ho mold cavity.

Ho futhumala ha foam karolo ea foam Via ento e lumella phofo ho lekola le ho fokotsa khatello ea eona e ka hare. Ts'ebetso e eketsehileng ea ho qeta, ho kuta mohala o chesang, ho hatisoa, ho hatisa, joalo, ho ka sebelisoa ho etsa kopo ea lits'ebetso tsa ho qetela.

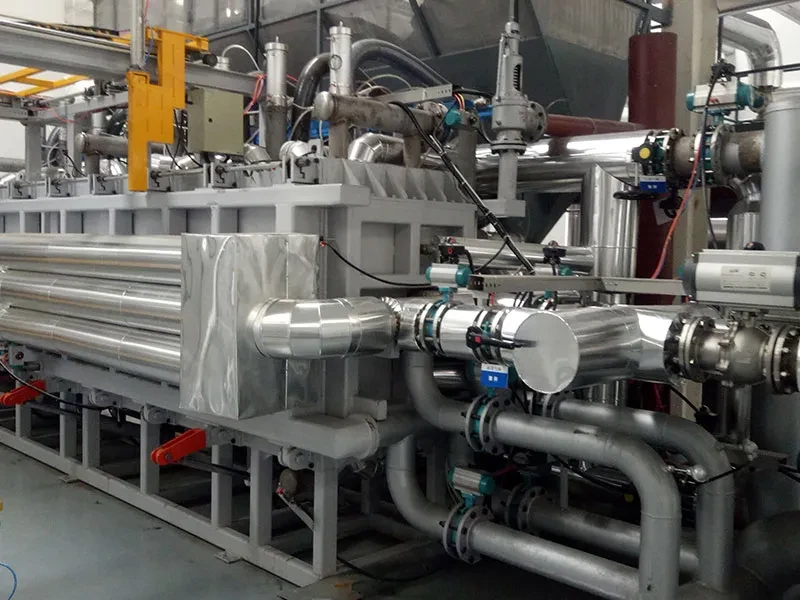

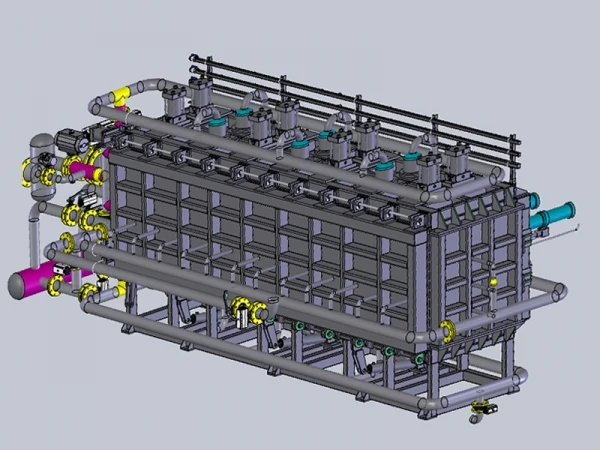

A. mmele oa mold

• Mochini ona o thibela lits'iseng o entsoe ka mofuta o otlolohileng ka mold sisteme e loketseng.

• 'Mele o na le mosebetsi o boima oa ho haha, entsoe ka tšepe ea carbon. Maboko a ka hare ke aluminum plate ka slots, bophara ba 5mm.

• thibela sets'oants'o sa boleng ba fusion ke sensor khatello ea khatello ea maikutlo.

• Litlhahlobo tsa motsoako (Aluminium simate fiber) ke ea boikhethelo.

B. Tlatsa Silo bakeng sa mochini oa li-eps tse thibelang

Ho tlatsa Silo e ka holim'a mochini oa li-eps tse thibeloang Yuniti e emisa mochini ha ho sa fumanehe ka mekhoa e lekaneng ea Silo.

C. Sistimi ea Stimading

Boemong bo bong le bo bong bo laoloa ke khatello ea mouoane e laoloang ka li-valve tsa mantlha tsa moholi le ka bomong ba tsamaisang ka lehlakoreng le leng. Haholo-holo ha u tšela Theknoloji ea ho futhumatsa e entsoe ka lenaneo. Steam e kenella ho tsoa ho li-hlobo tse peli tse tsoang ka mahlakore a mabeli le likotoana tse 4 tse nyane nakong ea ho futhumatsa.

D. Taolo ea taolo

Kabinete e ka sehloohong e nang le senotlolo sa ts'ireletso, e na le skrine ea Delta / Siamens

E. Block Ejection le yuniti ea boima

Ha o ntse o sebetsa ka botlalo, monyako o ka pele o bula le li-ejectors tsa Hydraulic li tla tlosa li-eps tse tlase monyako o ka pele. Kamora ho ja li-cylinders tse peli tsa moea ka lehlakoreng la mochini oa li-eps block ho tla sutumetsa sehlopha sa boima, kamora ho boima, leqhubu le tla otloloha.

F. Sistimi ea F. vauum

Tanka ea Condenenter Caban Ca. 0.8 m3 M3 Ka ho fafatsa metsi le ho hlapanya likarolo - tanka ea motho ka mong ea vacuum ca. 6m3. Lithaere tse peli tsa phomolo (11kw bakeng sa e 'ngoe le e' ngoe) e sebelisoang ho mochini. Ka thuso ea sekhukhu, e thusa ho fokotsa nako ea li-eps le dikahare tsa metsi.

Tlhaloso ea mochini oa eps

Mohlala: SPB (2000/3000/4000/5000/6000) r

• E loketse eps By block, 2000-6000mmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmmm

• E loketse eps block bophara: 1000-1200mmmmm

• E loketse eps blockness ea eps: 1000-1200mmmmmm

• 12-15 blocks / hora @ Density 15kg / m3

Lisebelisoa tsa mochini oa eps block

• Setifikeiti sa CE

• likarolo tse ngata tsa polokeho

• Mokhoa o mong oa ts'ebetso o ka khethoa: mohato kapa auto

• Boima ba 'mele, Tilter le Exit Block Conveler

• Homozeninonisong Dissity (+/-/-/- 3%)

• Tšebeliso e tlase ea matla le tlhahiso e phahameng

• Sisteme ea Ejection e iketsang, ho boima le sisteme ea Tilt

• Eps block sistimisiti ea boiketsetso e ntle.

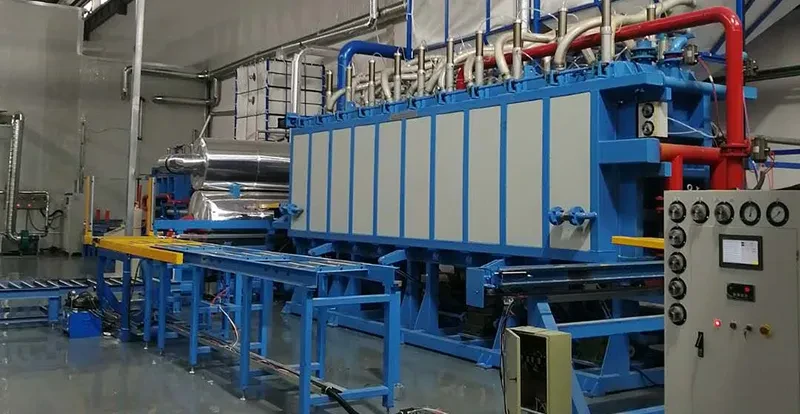

• Mmala oa mochini: Body Blue Ral5012 Blue + piping system ral3001 e khubelu

Sisteme ea eps Sisteves syction

Sistimi ea Convelothi ea block e laoloa ke ho ama Screen & PNC, sensor le Pneumatic, e tsamaisitsoeng ke koloi le liketane. Sisteme ea ho omisa ka boiketsetso ea fumaneha. E sebetsa lipakeng tsa li-eps tsa lits'ila tsa li-eps tsa boea le li-arting tse tsoelang pele ho khaola ho eketsa mohopolo oa semela, ho fokotsa matla a sebetsang le nako ea ho omisa. Ha mohala o le mong o tletse, sistimi e ne e ka emisa ho fepa mohala ona mme ka boeona e fetoloe mohala o mong. Ha mola o le mong ha o na letho, sistimi e ne e ka emisa ho hlakola mohala ona ebe o fetoha ho hlakola mola o mong.

Eps eps e thibela likarolo tsa mochini oa li-moying

• Ho ama + ho ama + plc: Delta / China

• khatello ea maikutlo: Uena/ China

• Litsebi: Schneider / France

• Mahala a aluminium: 2a12 / China

• Sethala sa serurubele: ABC Valve / Singapore

• Bo-Valve ea Boll: ABC Valve / Singapore

• Valve ea angle: esg / China

• Likarolo tsa PoneMatic: Airc / China

• Polum Pompo: Yulong / China

• Sensor ea Photo: Autononts / Korea