Umugqa ongcono wokuthengisa we-eps wokusika

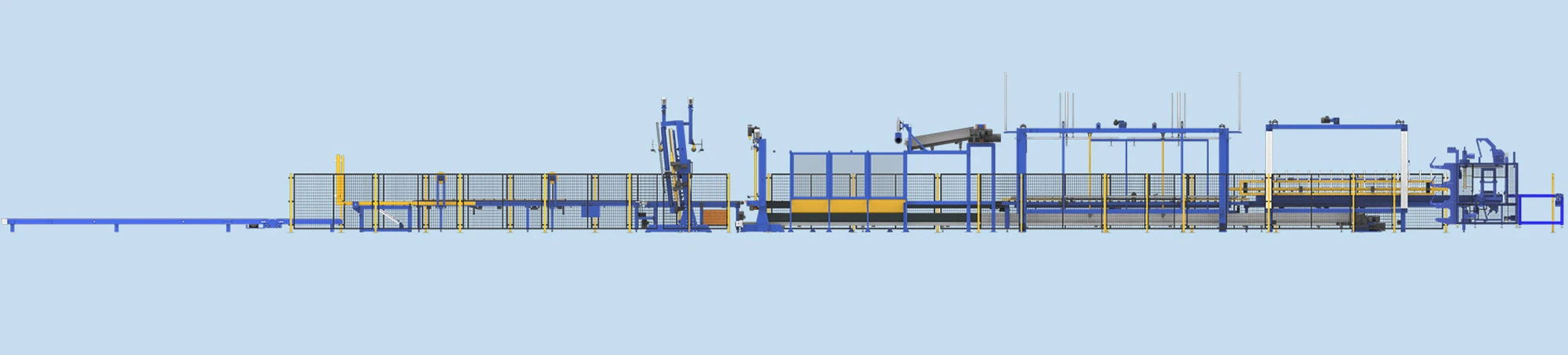

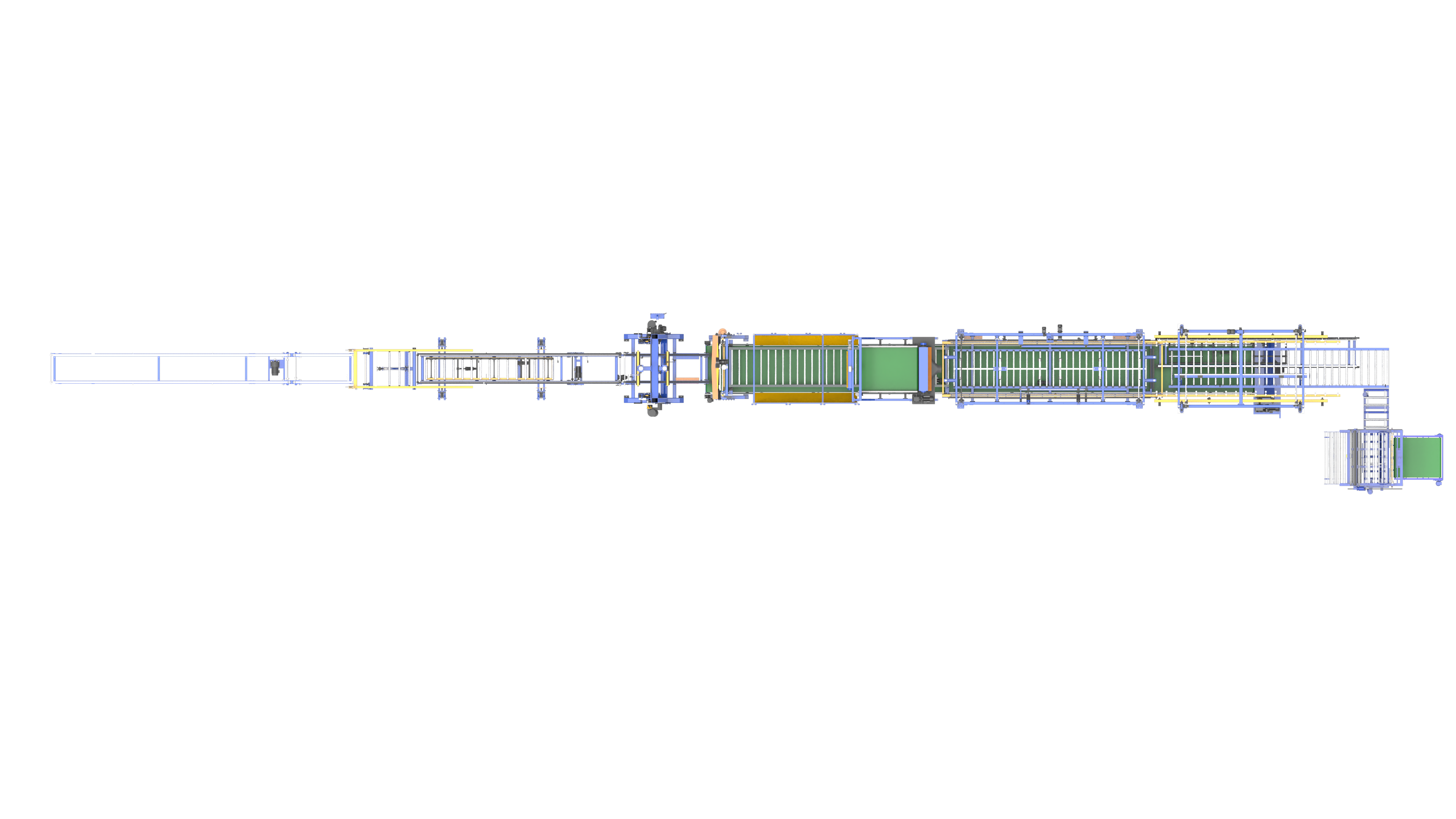

Umugqa wokusika we-eps

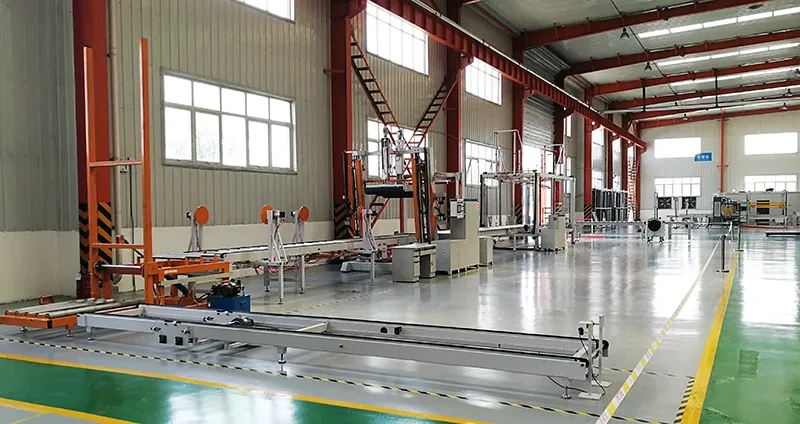

A. EPS Bkhiya hluthulela indawo yokugcina impahla

Amabhulokhi ayi-6 angagcinwa emgqeni. Amabhulokhi abekwe ngu-opharetha esebenzisa i-forklift.

Lapho i-tilter imahhala, ibhlokhi lizohamba liye kwiyunithi ye-tilter ukuze iqale ukusika isiteji ngokuzenzakalelayo.

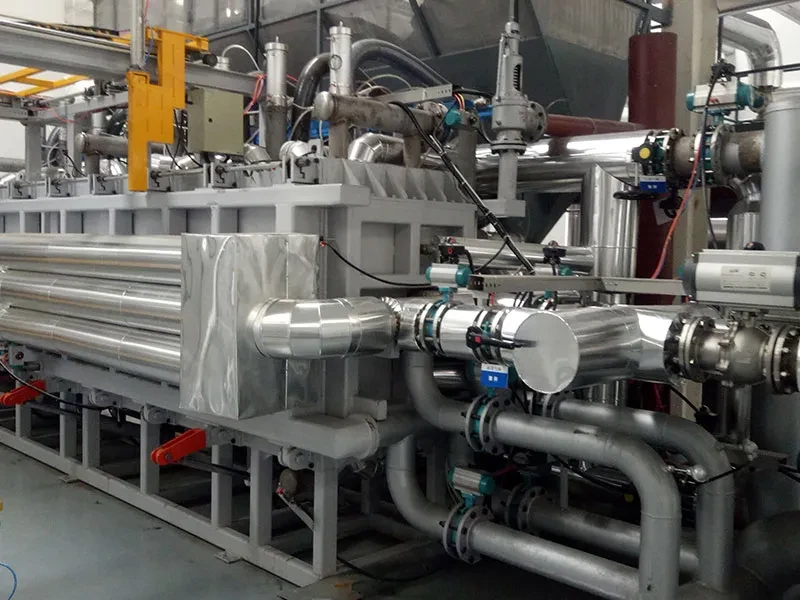

B. EPS Vimba iyunithi yokuthambisa

I-tilter iqhutshwa yi-hydraulic. Lapho i-block i-tilter ngokuphelele, iyunithi ibeka ibhlokhi phansi ku-endeing cutch chain conveyor bese uqhubekela phambili.

C. Hola ende block ukuhambisana

Lapho i-EPS block ifika inzwa ethile, isilinda somoya singaphila nge-EPS block kanye nama-4 pundurs avumelanise ibhlokhi le-EPS ngesikhundla esifanele sokusika, ukuqhubeka nokusika.

D. Cuta ovundlile

Uhlelo lokusetha nge-othomathikhi (Design Patent) & I-Oscillation Cut ifakwe kule ngxenye. Izintambo zibekwe ngokushesha okukhulu ekujuleni okukhulu. Izintambo ezingama-60 zingaxazululwa ngemizuzu engu-3, ukubekezelelana okukhulu ± 0.5mm. Abalandeli abane ezinhlangothini ezimbili zokupholisa ngocingo kanye nomlandeli oyedwa phansi.

E. ukusikwa okuqondile

Ukusika kwe-wire oscillation kuhlotshiswe kule ngxenye. Omunye fan ngaphezulu kwe-TOP & One One Phansi kuya phansi kuya eziphetho ze-wire.

Ukuhlelwa kocingo okuzenzakalelayo kungakhethwa.

F. Phezulu Scrap rI-Emoval & Pre-Crusher

Ifakwe iyunithi ye-vacuum suction, i-scrap ephezulu ngesikhathi sokusika ibizomunca ibhande lokuhamba bese lithathwa ku-crusher yangaphambi. Ngemuva kwalokho impahla echotshozwe ngaphambili edluliswa nge-fan ku-recycling system.

G. Cross cut & block ukuqondanisa

Ibhulokhi ingagawulwa ngobude obuhlukile ngokusika okuzenzakalelayo. Lapho i-block ingena kulesi sigaba ngokuphelele, uhlelo lokuqondanisa luzovumelanisa ibhlokhi le-EPS libe yisikhundla esifanele sokusika kahle ukuze sinqume ukunemba. I-wire ihamba kusuka phansi kuya phezulu. Ukuhlelwa kocingo okuzenzakalelayo, ukusikwa kwe-oscillation kungakhethwa.

H. othomathikhi othomathikhi & I-Side Scrup Recycling Unit

Ngemuva kokusika kwesiphambano, amaphakethe eza kusihambisi sokugcina esinenjini futhi alungele ukufaka i-de-stactor. I-de-stactaster ingaphila ingxenye engenhla ye-EPS block kuqala, futhi phansi i-EPS iyohamba ipakishe umshini kuqala. Ngemuva kwawo wonke amabhlogo aphansi agcwele, ingxenye engenhla ye-EPS yehlela phansi ku-conveyor bese iya ukupakisha.

Side Scrap & Crusher Pre-crusher pre-crusher kulesi sigaba. Ama-Scraps aqoqwa ngebhande lokuhamba liye ku-crusher pre-crusher. Ngemuva kwalokho impahla echotshozwe ngaphambili edluliswa nge-fan ku-recycling system.

Umshini wokupakisha we-EPS

Umshini wokupakisha we-EPS usebenzisa ifilimu ye-PE ukusonga amaphakethe e-EPS kusuka ezinhlangothini ezi-4. Idizayini ekhethekile ukugcina iphakethe lihlala isikhathi eside. Ijubane lokupakisha liyashesha futhi asikho isidingo sokushisa ifilimu ngohhavini. Ngemininingwane engaphezulu sicela uyithole kumakhasi omshini we-EPS esongelayo.

I-EPS yokusika umshini wokukhiqiza

Imodeli: SPQ (2000/3000/4000/5000/6000) B

• Ilungele ubude be-EPS block: 2000-6000mm

• Ilungele ububanzi be-EPS block: 1200mm

• Ilungele ubukhulu be-EPS block: 1200mm

• Isivinini sokusika: 1.8 ~ 2M / Min / Men @ density 15kg / m3

Izici ze-EPS zokusika

• Isitifiketi se-CE

• Izici eziningi zokuphepha

• Ukukhishwa okuphezulu nge-automation ephezulu

• Ukuhlelwa kocingo okuzenzakalelayo ku-ende cut cut, vertical and cross cut kungakhethwa

• I-Oscillation Sika ekusikeni okuqondile okuqondile okuqondile kanye nokusika kwesiphambano kungakhethwa

• I-Hot Wire iphela ukupholisa

• Phezulu, uhlangothi kanye nesikhafu esingezansi kuyatholakala

• Uhlelo lokuxwayisa nge-Wire Break luyakhethwa

• Umshini ungenziwa ngokwezifiso ngokusekelwe esicelweni esikhethekile somsebenzisi

• Umbala womshini: Isikhunta somzimba RAL5012 Blue + Ral1021 Ophuzi