I-Polystyrererererenererererenererene (EPS) isiye yabaluleke kakhulu ezimbonini ezisukela ekufakweni kokwakha ekuzilolongweni okuvikelayo. Uma usebenzisa ibhizinisi lokukhiqiza le-EPS Foam, uyakuqonda ukuthi ukusebenza kahle nokunemba kubaluleke kakhulu. Le khasiumugqa ozenzakalelayo wokusika we-EPSimele ukugxuma okukhulu phambili ekusebenzeni amabhlogo we-EPS. Le ndatshana idonsela ukujula kule ngxenye ebalulekileizikhali nenzinye izinto, echaza ukuthi isebenza kanjani, izinzuzo zayo, kungani kungukutshala imali okubalulekile kwamabhizinisi afana nokwakho, nokuthi yini okufanele uyicabangele lapho ukhetha eyodwa. Ukufunda lokhu kuzokunikeza ukuqonda okudingekayo ukuze uthole owakhoumkhiqizofuthi uhlale umncintiswano.

Kuyini ngempela umugqa ozenzakalelayo wokusika we-ePS?

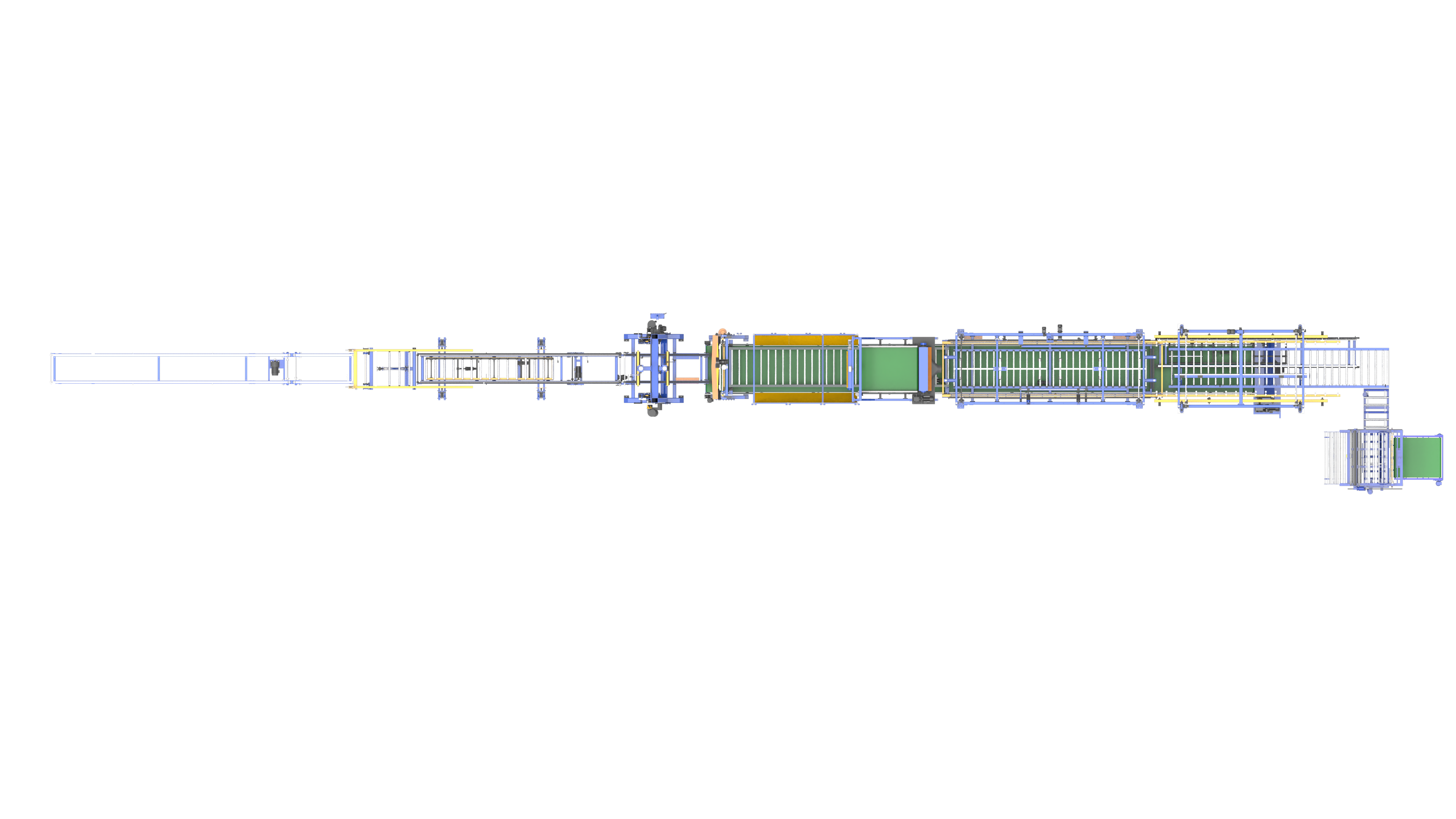

Emgodini wayo, aumugqa oqhubekayo wokuqina we-ePSuhlelo oluyinkimbinkimbi olwenzelweukusika-ningiAmabhulokhi e-EPSemashidini noma amajamo athile anokungenelela komuntu okuncane. Ngokungafani ne-Standaloneumshini wokusikaamayunithi lapho amabhlokhi angadinga khona ukulayisha okwenziwe ngesandla nokubuyisela kabusha ukusikeka okuhlukile, aumugqa wokusika oqhubekayo we-ePSezenzakalelayo yonke inqubo. -NingiAmabhulokhi e-EPS, kuvame ukuza ngokuqondile kusuka kuIsikhunta esiguqukayo se-EPS block umshini wokubumba, adliwa emgqeni, ngokujwayelekile ngezihambisi.

Uhlelo bese luphatha ngokuzenzakalelayocina, ukuyihambisa ngokuhlukahlukeneusikeniiziteshi. Lezi ziteshi ziqashiweucingo olushisayoubuchwepheshe ukwenza kahleukusikeka. Okokuqala, acinakungadlula ngokuqondileumsikiIsigaba sokuwusika sibe ngamashidi obukhulu obufunayo. Ngemuva kwalokho, la mashidi angaqhubekela phambili mpoumsikiisigaba ukuze sibeukusikaububanzi obuthile noma ubukhulu bokugcina. Isici esithi "Ukuqhubeka" sisho ukuthi inqubo igeleza kahle kusuka kusinyathelo esisodwa kuya kwesilandelayo ngaphandle kokuma, yandise ukukhishwa. Ingxenye ye- "Automato ezenzakalelayo" icacisa ukuthi izinzwa, ama-PLCs (abalawuli abahlekisayo), kanye nama-motors baphatha ukondliwa, ukuma,usikeni, futhi kwesinye isikhathi nokulayishwa kwezicucu eziqediwe. Leliumugqa wokusika we-epsi-extered yevolumu ephezuluumkhiqizo.

Njenge-umenziOchwepheshe ku-EPSizinsimbi zomshini, sikubone mathupha ukuthi kusetshenziswe kanjaniumugqa ozenzakalelayo wokusikaiguqula phansi kwefekthri. Ihambisa imisebenzi ekusebenzeni nasekuqaliseni ukucubungula ku-fluid, ukuhamba komsebenzi okusebenzayo. Lolu hlelo lungaphezu kokumane nje aumshini wokusika; Kuhlanganisweisixazululoyakhelwe ukuphathawanwebeka polystyreneamabhlokhi ngokuhlelekile nangendlela efanele. Umnyomboimbuyiseloamanga emandleni ayoukushintshaimisebenzi ephindaphindwayo, ukuqinisekisa ukungaguquguquki kanye nesivinini.

Kungani kufanele ibhizinisi lakho le-EPS Foam litshale imali ekuqhubekeni kobuchwepheshe bokusika?

Ukutshala imali ku-Newizikhali nenzinye izintoUhlala uyisinqumo esibalulekile, ikakhulukazi umnikazi wenkampani njengoMark Thompson, olinganiselayo ikhwalithi esebenza kahle. Ngakho-ke, kungani ucabangele aumugqa wokusika oqhubekayo we-ePS? Umshayeli oyinhlokoikhono lokwenza. Ngesandla noma okuzenzakalelayousikeniIzindlela zibandakanya abasebenzi ababalulekile, amandla ephutha lomuntu, kanye nesikhathi sokuphumula phakathiukusikekanoma ukuphakanyiswa okuvinjelwe. A-zishintshayoIsistimu isebenza ngokuqhubekayo, ukuphuma kwakhula kakhuluokukhiqiza. Lokhu kusho ukuthi ungacubungula okuningiI-Eps FoamNgesikhathi esincane, ukufeza ama-oda amakhulu ngokushesha okukhulu futhi kube lula ukunciphisa izikhathi zokuhola kumakhasimende akho.

Ngaphezu kwalokho, ukuguquguquka kubalulekile ekukhiqizeni ikhwalithi ephezuluI-Eps Foamimikhiqizo. Aumugqa ozenzakalelayo wokusikaiqinisekisa ukuthi njaloukusikakwenziwa ngokufanayoukwenza kahlekanye nesivinini, ngokuya ngamapharamitha abekwe ngaphambilini. Lokhu kunciphisa ukungcola okubonakalayo okubangelwa okungalungileukusikekafuthi ithuthukise ikhwalithi ephelele yezimpahla zakho eziqediwe, noma ngabeukwahlukanisaamaphaneli noma inkambisouhloboukupakisha. Ukuncishiswa kokuphathwa ngesandla nakho kuthuthukisa ukuphepha emsebenzini ngokunciphisaosebenzayoukusebenzisana neUkusika ucingoizindlela.

Kwamabhizinisi ahlose ukukala, aumugqa oqhubekayo wokuqina we-ePSkucishe kubalulekile. Ikuvumela ukubaukukhulaIvolumu yokukhiqiza ngaphandle kwezindleko ezandayo zabasebenzi. Ukutshala imali kokuqala kungahle kubuyiselwe ngaphezuluikhono lokwenza, imfucumfucu yanciphisa, izidingo eziphansi zabasebenzi, kanye nekhono lokuthatha izinkontileka ezifunwa kakhulu. Siyaqonda ukuthi isimo sokuncintisana, ikakhulukazi sitholaIzitsha zokudlela zebumba uqobo, nalolu hlobo oluthuthukileizinsimbi zomshiniihlinzeka ngokusebenza okuhlukileimbuyiselo, kukusiza ukukhiqiza izindleko ezisebenzayo, ezisezingeni eliphakemePolystyreneimikhiqizo. Cabanga ngeukukhuphuka kahle kokusebenza kahle- Kuvame kakhulu.

Ngabe umshini wokusika oshisayo oshisayo usebenzela kanjani amabhlogo we-eps?

Umlingo ngemuva ngokunembileUkusika okunwetshiwe kwe-polystyreneamanga kuucingo olushisayoubuchwepheshe. Aumugqa wokusika we-epsIsebenzisa izintambo ezincanyana, ezingamelana nazo, ezenziwe nge-nichrome noma i-alloy efanayo, eshiswe ngokuqondileizinga lokushisa nokubandange-ejeka yamanje. Lapho kufudumeleuwayakuhlangana neI-Eps Foam, akukuboni ngomshini; Esikhundleni salokho, kuncibilikaPolystyreneendaweni kanyeukusikaindlela. Lokhu kuphumela ngokumangazayo-bushelezifuthi ngokunembileukusikaingaphezulu nothuli oluncane noma imfucumfucu eqhathaniswa nezindlela zokubona.

Ngaphakathi kwe-umugqa oqhubekayo wokuqina we-ePS, eziningiizintambo ezishisayobathenge kahle futhi babeka ngaphakathi kwamafreyimu wokusika. Ngokuvundlileukusikeka, izintambo zelulwa ngaphesheya kwendlela yokuhambaI-EPS block. Njenge-cinaintuthuko (nomauwayaUhlaka luhamba),ucingo olushisayoizingcezu zayongokuvundlile, ukudala amashidi. Ngokuqondileukusikeka, izintambo zithambekele phezulu-kuya phezulu, futhi amashidi adlula kuwo (nomauwayaUhlaka luhamba ngaphesheya kwamashidi) ukufeza ububanzi obufunayo. Izinhlelo ezithuthukile zivame ukufaka i-anoscillateUmsebenzi, laphoUkusika ucingoidlidliza ngokushesha ngobude bayo. LeliUkusika okudlidlizaIsenzo sisiza ukusula izinto ezincibilikile, ukuthuthukisa kabushaukusikaikhwalithi nangejubane, ikakhulukazi ku-denserI-Eps Foam.

Le khasiizinga lokushisa nokubandayeuwayakanyeIsivinini sokusikaamapharamitha abucayi alawulwa yi-PLC yohlelo. Lokhu kudinga ukulinganiswa ngokucophelela ngokuya ngobuningi beI-EPS blockfuthi ofiswayoukusikaIkhwalithi. Kushisa kakhulu noma kancane kakhulu, kanyeukusikaingaba banzi kakhulu noma incibilike; Kuhle kakhulu noma kushesha kakhulu, futhiuwayaingahle idonsele noma yephule. -Isimanjeumugqa wokusika we-epsamasistimu avame ukufaka izinhlelo zokulawula eziyinkimbinkimbi ezivumela i-osebenzayoukusetha kalula futhi uguqule la mapharamitha-hle kakhuluImiphumela, Ukuqinisekisa UkuvumelanaUkusika foam. LeziAma-Hot Wire Wireinhliziyo kaJehovaUkusika foaminqubo.

Yiziphi izingxenye ezibalulekile zomugqa wokusika osebenza ngokuphezulu?

Ukusebenza okuphezuluumugqa oqhubekayo wokuqina we-ePSkungaphezu nje kwalokhoizintambo ezishisayo. Kungumhlangano wezakhi ezihlanganiswe ngokucophelela ezisebenza ekhonsathini. Ukuqonda lezi zingxenye kusiza ekuhlolweni kwezinhlelo ezahlukahlukene:

- Isihambisi / uhlelo lokuthola ulwazi:Leliiceboithola okukhuluAmabhulokhi e-EPS(imvamisa ngokuzenzakalela kusuka kwisitoreji noma umshini wokubumba wokubumba) bese uzihambisa ngokushelela kokuqalausikeniIsiteshi. Ibhande noma ama-roller vetezors ajwayelekile. Ezinye izinhlelo zifaka izindlela zokulinganisa ukuhambisa iziqu ku-Orient Thecinakahle.

- Isiteshi sokusika esivundlile:Lesi sigaba sinezinto ezithambekele ezivundlileizintambo ezishisayo. KubandakanyauwayaAmafreyimu, izindlela zokushintshana, kanye nokunikezwa kwamandla / ukulawulwa kokushisa izintambo. Uhlaka lungahle ludlulele phezulu naphansi, noma ukuphakama kokuhambisa kuvumelana, ukunquma ubukhulu beshidi. Ukunemba kweUkuhlelwa kwentamboNakhu kubalulekile.

- Isiteshi sokusika mpo:Ngemuva kokukhanya okuvundlile, lesi siteshi senza mpoukusikeka. Ifana nesiteshi esivundlile, inenkinga yethempeliizintambo ezishisayo. Isika amashidi ibe yimichilo emincane noma ububanzi bomkhiqizo wokugcina. Futhi, ngokuqondileUkuhlelwa kwentamboubalulekile.

- Isiteshi sokusika (ngokuzithandela):Eminye imigqa ifaka esiteshini kuyeukusikaimichilo noma amashidi ngobude obuthile usebenzisa enye isethi yeizintambo ezishisayonoma kwesinye isikhathi ibalaumsiki.

- Uhlelo Lokususa Udoti:-QeqeshekaImigqa yokusika ye-EPSfaka amasistimu ukuqoqa imfucumfucu (imiphethoukusikaoff thecina). Lokhu kuvame ukubandakanya ukuhambisa noma amasistimu we-vacuum ahambisa isikhafuIndwangu ye-EPSubheke aUmshini wokuphinda usebenzise kabusha umshini we-eps crusher + de-duster + uthuliukucubungula, ukugcinaIndawo Yokusebenzaihlanza.

- Ukuphuma nohlelo lokufaka (kuyakhetheka):Kamuvausikeni, izingcezu eziqediwe zihanjiswa. Imigqa ethuthukisiwe ingahlanganisa ukufakwa okuzenzakalelayo nomaukufaka ndawonyeizixazululo njengeUmshini wokufaka u-ePSUkulungiselela imikhiqizo yokuthumela ngebhukwana elincaneukupheka.

- Uhlelo lokulawula (PLC & HMI):Ubuchopho beukuhlinza. I-PLC ilawula wonke ama-motors, isivinini,uwayaamazinga okushisa, kanye nokulandelana. Isikhombimsebenzisi somshini womuntu (HMI), imvamisa ipaneli yesikrini sokuthinta, livumelaosebenzayoUkusetha amapharamitha, qapha inqubo, nezinkinga zokuxazulula izinkinga. Isikhombimsebenzisi esisebenziseka kalula sibalulekile ukuze sisebenze kahleukuhlinza.

Sisinyeingxenyekumele yakhelwe kahle futhi injiniyela ngokuqondile ukuze iqinisekise ukuthembeka futhiikhono lokwenzaukuthi abasebenzisi abanjengoMark Thompson balindele. Njenge-Umshini womshini, sigxila kakhulu kwikhwalithi nokuhlanganiswa kwalezi zingxenye.

Ungakwazi yini ukuthola ukusika okuphezulu okuphezulu ngomshini wokusika othomathikhi we-EPS?

Impela. -Phezuluukwenza kahlekungenye yezinzuzo eziphambili zenzelwe kahleumshini wokusika othomathikhi we-epsnoma umugqa. Kunezici eziningana ezinikela kulokhu:

- Uhlaka oluzinzile:Konkeumugqa wokusika we-epsisakhiwo kumele sibe luqinile futhi sidliwa-mahhala ukuqinisekisaUkusika izintambogcina isikhundla sabo ngqo esihlobene neI-EPS block. Noma yikuphi ukuguquguquka noma i-webble kungaholela ekungalungileukusikeka.

- Ukufakwa kwentambo okuqondile:Izinhlelo zanamuhla zisebenzisa izindlela eziqondile, zivame ukubandakanya ama-servo motors noma ama-motorper stepper ngezikulufo eziholayo, ngokubeka isikhundlaucingo olushisayoozimele. Lokhu kuvumela ukubeka okufisayoukusikaUbukhulu (ubukhulu, ububanzi) ngokubekezelela okuqinile kakhulu, imvamisa ngaphakathi kwamamilimitha noma ngaphansi.

- Izinhlelo ezenzakalelayo zokubeka i-wire:Imigqa ethuthukisiwe ingahle ifake i-anuhlelo lokusetha nge-othomathikhi. Lokhu kuvumelaosebenzayoUkufaka ubukhulu obuyifunayo nge-HMI, nomshini-zithayo ngokuzenzakalelayo ngokuzenzakalelayoilungisauwayaIzikhundla, ukonga isikhathi esibalulekile sokusetha futhi kunciphise amathuba amaphutha ngokuqhathaniswa nemanyuwaliUkuhlelwa kwentambo. Lokhu kuyasizathuthukisa ukusikwaukunemba kakhulu.

- Ukungezwani okungaguquki:Ukugcina ukungezwani okungaguquki kokukodwaUkusika ucingokubalulekile. Izintambo ezi-slack zingakhothama noma zikhule ngesikhathiukusika, okuholela ezindaweni ezingalingani noma ezingalungile. Izinhlelo ezizenzakalelayo ze-tenyoning zisiza ukugcina kahleuwayaukungezwani kulo lonkeukuhlinza.

- Ukunyakaza okulawulwayo:Ijubane laphoI-EPS blockihamba ngeusikeniiziteshi, nejubane lanoma yikuphi ukunyakazauwayaAmafreyimu, kumele alawulwe ngokunembile futhi avumelaniswe. Ukuhamba okubushelelezi, okuguqukayo kuvimbela ukunyakaza kwe-jerky okungathintaukusikaIkhwalithi.

- Ubuchwepheshe be-Oscillation:Njengoba kushiwo ngaphambili,oscillatingIzintambo zingathuthukisaukusikabushelelezi futhiukwenza kahle, ikakhulukazi ngento eyinkimbinkimbibobubinoma izinto ezinkulu.

Lapho lezi zinto zinziwe kahle, aumugqa ozenzakalelayo wokusikaIhambisa kakhulu-yikho ngqofuthi kuyaphindwaukusikeka, ukuqinisekisa ukuthi owokugcinaI-Eps FoamImikhiqizo ihlangabezana nokucaciswa okuqondile kwezicelo ezinjengezokwakhaukwahlukanisa, ukusetshenziselwaukufaka ndawonye, noma inkambisouhloboukufakwa kokubumba. Leli zinga leukwenza kahleKunzima, uma kungenzeki, ukufeza njalo ngezindlela zezandla.

I-automation ithuthukisa kanjani kakhulu inqubo yokusika ye-EPS?

I-automation yitshenti leikhono lokwenzakanye nokwethembeka okunikezwe yiumugqa wokusika oqhubekayo we-ePS. Ake sihlukanise nokuthi sithuthukisa kanjani inqubo:

- Umsebenzi oncishisiwe:Inzuzo esobala kakhulu. Umsebenzi wezandlausikeniDinga amabhulokhi, ukukala, ukuqondisaukusika, ukuphindaphinda ngokulandelayoukusikeka, bese uthulula izingcezu eziqediwe. A-zishintshayoUmugqa uphatha iningi, uma kungenjalo konke, kwale misebenzi-zithayo ngokuzenzakalelayo ngokuzenzakalelayo, ukunciphisa kakhulu inani labasebenza abadinga umugqa ngamunye. Lokhu kukhulula abasebenzi ngeminye imisebenzi kanye nezindleko ze-lower zabasebenzi.

- Ukwanda kokuqashwa:I-automation iqeda ama-mause engokwemvelo emisebenzini yezandla (isikhathi sokusetha, isikhathi sokuphatha, ikhefu le-opharetha). Le khasi-qhubekayoUkugeleza kuvumelaumshini wokusikaukucubungulaAmabhulokhi e-EPSngokushesha okukhulu, okuholela ekutheni kube yinto enkuluukukhulaku-jikeleleumkhiqizoivolumu.

- Ikhwalithi engaguquki:Opharetha bangabantu bangaba nokuhluka lapho benza ngayoukusikeka, okuholela ekungathobekisweni. I-automation ifaka ngakunyeukusikaNgokuya ngokususelwa kumapharamitha ahlelwe, uqinisekise ikhwalithi yomkhiqizo ofanayo kanye nobukhulu, i-batch ngemuva kwe-batch. Lokhu kuncipha kuyenqabela nokungcola.

- Ukuphepha Okuthuthukisiwe:Ezenzakalelayo ukunyakaza okukhuluAmabhulokhi e-EPSkanyeInqubo yokusikangokwayo inciphisa isidingo sabasebenza ukuthi basondele ekusondeleni izingxenye futhiizintambo ezishisayo, ethuthukisa kakhulu ukuphepha emsebenzini.

- Ukusetshenziswa okwenziwe kahle kwezinto:Ngokuqondile, ezenzakalelayoukusikekanciphisa imfucumfucu yokunquma. Izinhlelo ezihlanganisiwe zokususa imfucuza zingakwazi ukuqondisa ngokushesha isikhafusebenzisa kabusha, Ukwenza ngcono isivuno sezinto ezibonakalayo kanye nokusimama.

- Ukusebenza okwenziwe lula:Ngenkathi ubuchwepheshe obungaphansi buyinkimbinkimbi, i-HMI yesimanje yenza ukusebenza komugqa oqondile. Lapho amapharamitha asethelwe, theosebenzayongokuyinhloko ubheka inqubo, wenza ushintsho njengoba kudingeka. Lokhu kunciphisa isidingo samakhono akhethekile kakhulu okuyisisekeloukuhlinza.

NgokushintshaUkusika kwe-EPSinqubo, abakhiqizi bangafinyelela ngaphezuluikhono lokwenza, Ukulawulwa kwekhwalithi okungcono, ukuphepha okuthuthukile, futhi ekugcineni, ukusebenza okuncintisanayo. Umgomo ukuukushintshaImisebenzi ephindaphindwayo, edinga ukuphakamaukwenza kahle, noma ukubeka izingozi zokuphepha, ukuvumela abasebenzi babantu ukuthi bagxile ekubhekaneni nasekulawulweni kwekhwalithi.

Ukukhetha ngokuhlakanipha: Yini okufanele uyibheke kumkhiqizi we-EPS osika umugqa?

Ukukhetha kwesokudlaumenziOkwakhoumugqa wokusika we-epskubalulekile njengokukhetha umshini uqobo, ikakhulukazi lapho ukotha umhlaba wonke, mhlawumbeIzitsha zokudlela zebumba uqobo. Kumuntu onjengoMark Thompson, okwazisa ikhwalithi nokuthembela kanye nentengo, nazi izici ezibalulekile okufanele zicatshangelwe:

- Isipiliyoni nobuchwepheshe:Funa aumenzingerekhodi elifakazelwe ngokuqondileI-EPSne-EPPImishini ye-Foam. Izinkampani lokhoukuqoka umkhakha othize wolwaziQondisisa ama-nuances wokusebenza nawowanwebeka polystyrenenemishini yokuklama ngokufanele. ULili ubelokhu kulokhuimboniiminyaka, igxile kuphela kulolu hloboizikhali nenzinye izinto.

- Ukucaciswa kobuchwepheshe kanye nekhwalithi yokwakha:Qoka ama-specs omshini. Iziphi izinto ezisetshenziswayo? Izingxenye zitholwe kubathengisi abadumile (isb., Nokia, Schneider for-gesiizingxenye)? Ingabe i-Frame rose? Cela imininingwane mayelana nama-motors, amasistimu okulawula, kanyeuwayaubuchwepheshe.

- Izinketho zokwenza ngokwezifiso:Can theumenziTailor theumugqa wokusika we-epskwizidingo zakho ezithile mayelanaUbukhulu Bokuvimba, usikeniUbukhulu, Izidingo Zejubane, noma Ukuhlanganiswa Nakho Okukhonaizikhali nenzinye izinto? Umlingani omuhle usebenza nawe ukuhlinzeka okungcono kakhuluisixazululo.

- Isevisi Yokuthengisa Ngemuva Nokusekelwa:Lokhu kubalulekile. Hlobo luni lokuxhaswa kokufaka, ukuqeqeshwa opharetha, nosizo lwezobuchwephesheumenziNikela? Ingabe Ukuxilongwa Okukude Kuyatholakala? Bangaphendula ngokushesha kangakanani uma kuvela izingqinamba? Izithiyo zolimi zingaba iphuzu lobuhlungu, ngakho-ke qiniseka ukuthi iziteshi zokuxhumana ezicacile zikhona. E-Youli, sibeka phambili ukusekelwa okuphelele kwamakhasimende ethu aphesheya.

- Ukutholakala kwezingxenye ezisele:Imishini idinga ukulungiswa nokubuyiselwa kwezikhathi ezithile. QinisekisaumenziInenqubo ecacile yokuhlinzeka ngezingxenye ezisele ngokushesha nangezindleko ezinengqondo. Ukutholakala kwe-Downstream kwezingxenye ezinjengeUkusika ucingokubalulekile.

- Izitifiketi Nokuhambisana:Yenzaizinsimbi zomshiniHlangana namazinga okuphepha aphesheya (e.g., Ukumaka iYurophu)? Lokhu kuqinisekisaizikhali nenzinye izintoYakhiwa ngokuphepha futhi ingahle ifuneke ngezinhloso zokungenisa ngaphakathi noma zomshuwalense.

- Izikhombo nezifundo zecala:Cela izinkomba ezivela kwamanye amakhasimende, ikakhulukazi esifundeni sakho (e-USA, eNyakatho Melika, eYurophu, e-Australia). Ukuzwa ngokuhlangenwe nakho kwabo kunganikeza ukuqonda okubalulekile kuUmkhiqiziukuthembeka nokusebenza.

- Ukusobala kanye nokuxhumana:Hlaziya inqubo yokuxhumana ngesikhathi sesigaba sokuthengisa. Ngabe bayaphendula, banolwazi, futhi esobala ngamakhono nokulinganiselwa? Lokhu kuvame ukubona ukuthi bazokusingatha kanjani ukusekelwa kamuva. Silwela ukuxhumana okucacile, okuqondile namakhasimende afana noMark.

Intengo ihlala iyinto, kepha akufanele ibekuphelaisici. Umshini oshibhile onokwethenjwa okungekuhle noma ukwesekwa okunganele kungagcina kubiza kakhulu ngokuhamba kwesikhathi ngenxa yesikhathi sokuphumula futhi kulahlekileumkhiqizo.

Manual vs Ukusika okuzenzakalelayo kwe-EPS: Ukubukeka okucacile kokuthola amandla okuzuza

Masinciphise umehluko. Ngenkathi izibalo eziqondile zincike kokuthileUsayizi we-EPS block, ukuqina, futhi kuyadingekaukusikakuyinkimbinkimbi,ikhono lokwenzaukuzuza kusuka ekushintsheni kwencwadi kuya kuumugqa oqhubekayo wokuqina we-ePSzivame ukumangalisa.

| Ubuso | Ukusika kwe-Manual / Semi-okuzenzakalelayo | Umugqa oqhubekayo wokuqina we-ePS |

|---|---|---|

| Ukusebenza | Phezulu (opharetha abaningi bokulayisha, ukusika, ukuphathwa) | Ephansi (ngokujwayelekile 1 opharetha wokuqapha) |

| Phendukela | I-Low to moderate (limited ngejubane lezincwadi nokuphatha) | Ephezulu kakhulu ephakeme kakhulu (ukugeleza okuqhubekayo, okuzenzakalelayo) |

| Ukungacabangi | Ukuguquguquka (kuya ngekhono lokusebenzisa nokukhathala) | Phezulu (ukunemba komshini, ukusikeka okuphindaphindekayo) |

| Izibi | I-Moderate to High (Ingozi yamaphutha, ukusikeka okunembile) | Okuphansi (ukunemba okuphezulu, ukusetshenziswa okwenziwe kahle kwezinto) |

| Isikhathi sokusetha | Isikhathi eside (ukukalwa kwesandla, ukulungiswa kwentambo) | Okufushane (ipharamitha okokufaka nge-HMI, ukulungiswa okuzenzakalelayo) |

| Ukuphepha | Ingozi ephakeme (ukusondela kwe-opharetha kuya ezintanjeni ezishisayo / ama-blade) | Ingozi ephansi (ukuncishiswa kokusebenzisana kwe-opharetha) |

| Ukuvumelana nezimo | Ingaba phezulu kokusikeka okukodwa, kepha kancane | Phezulu kwamaphethini ahlelwe, ushintsho olusheshayo |

| Isikhala saphansi | Kungaba yincane amayunithi angashadile, kepha ukugeleza okungasebenzi kahle | I-Footprint Ekhudlwana Yezinyawo, Kepha Ukuhamba Ngokusebenza Kakhulu Whamplow |

Cabanga ngesimo: NgesandlausikeniindinganisoI-EPS blockAmashidi amaningi angathatha imizuzu eminingana ngebhulokhi ngalinye, kufaka phakathi ukuphathwa. Aumugqa ozenzakalelayo wokusikakungenzeka icubungule okufanayocinaEngxenyeni yalesosikhathi, mhlawumbe ngaphansi komzuzu, futhi wenze njalo ngokuqhubekayo. Lokhu kuhumushela ekuphindiseni kwakhoUkusika umthamokaninginingi ngaphezulu. Le khasiukukhuphuka kahle kokusebenza kahleAkumane nje kubhaliwe; Ngokuvamile kuguqulwa, okuvumela amabhizinisi ukuba ahlangabezane nokudingayo futhithuthukisainzuzo kakhulu. Le khasiIsivinini sokusikakuthuthukiswa kakhulu, kunomthelela ngqoumkhiqizoisilinganiso.

Ukugcina kugijima: Yikuphi ukunakekelwa okuzenzakalelayo kwe-EPS ukusika komugqa okudingayo?

Njenganoma iyiphi impahla yezimboniizinsimbi zomshini, aumugqa oqhubekayo wokuqina we-ePS-khwithithitaukulungiswa okujwayelekileukuqinisekisa-hle kakhuluukusebenza, isikhathi eside, nokuphepha. Ngenkathi yakhelwe kahle, ukunganaki ukulondolozwa kungaholela ekunciphiseniukwenza kahle, isikhathi esingalindelekile, futhi ukulungiswa okungabizi kakhulu. Nakhu ukubuka konke okujwayelekile:

- Amasheke nsuku zonke:

- BhekaUkusika izintamboUkugqoka, ukulimala, noma ukusatshalaliswa kwesakhiwo. Faka esikhundleni izintambo ezigqokwa ngokushesha.

- -Hlolauwayaukungezwani.

- Qinisekisa ukuthi onogada nezinzwa zokuphepha zisebenza kahle.

- Hlanza izindawo ezifinyelelekayo zothuli kanye nemfucumfucu.

- Ukulungiswa Kweviki:

- Hlanza kahle umshini, kufaka phakathi amabhande okuhambisa / ama-roller kanye nezindawo zokuqoqa imfucuza.

- Gcoba izingxenye ezihambayo (ama-bearings, izinkombandlela) njengoba kuchaziwe yiumenzi.

- Hlola amabhande drive noma amaketanga ngokungezwani okufanele nokugqoka.

- -Hlola-gesiUkuxhumana nezintambo zezimpawu zomonakalo.

- Ukulungiswa Kwenyanga Njalo:

- Ukuhlolwa okuningi okujulile kwezingxenye zemishini (ama-motors, ama-gearbox).

- Qinisekisa ukulinganisa kwezinhlelo zokubeka isikhundla uma kudingeka.

- Bheka uhlelo lokulawula (PLC) nganoma yiziphi izingodo zamaphutha.

- Hlolaucingo olushisayouhlelo lokushisa nezilawuli.

- Ukulungiswa Kwaminyaka yonke:

- Cabanga ngensizakalo ebanzi ngokwengeziwe, ngokunokwenzeka uchwepheshe ofanelekayo nomaUmkhiqiziIthimba Lokusekelwa. Lokhu kungafaka ukubheka ukuqondanisa, ukufaka izingxenye zokugqoka ngokufanele, kanye nokuvuselelwa kwesoftware uma kusebenza.

Ukuba nohlelo olucacile lwesondlo kanye nezingxenye ezitholakala kalula zibalulekile. Thina, njengeUmshini womshini, hlinzeka ngemihlahlandlela enemininingwane yokulungiswa futhi uxhase amaklayenti ethu ekususeni izindlela ezisebenzayo. Ukulungisa ama-Mark Thompson Cain Point Point mayelana nezingxenye ezisele, abakhiqizi abathembekile baqinisekisa ukuthi kubushelelezi ukuhlinzekwa kwezitolo okufana nokudla okufanaUkusika ucingokanye nezinto ezibucayi zokufaka esikhundleni. Ukulungiswa okufanele kuyisihluthulelo sokwandisa ukubuyiselwa kwemali yakho kuumugqa wokusika we-eps.

Ngaphandle kokuncipha okuyisisekelo: ukuhlola amakhono emishini yokusika ye-CNC emugqeni

Ngenkathi abaningiImigqa eqhubekayo eqhubekayo yokusika ye-EPSGxila ekukhiqizeni amashidi kanye namabhulokhi amaxande, ubuchwepheshe bungahlanganiswa nokuthuthuka okuphezuluusikeniAmakhono, okungukuthiI-CNC (Ukulawulwa Kwezinombolo Zekhompyutha). AUmshini wokusika we-CNCisebenzisa ukulawulwa kwekhompyutha ukuqondisaucingo olushisayoemikhondweni eyinkimbinkimbi, evumela ukudalwa kwe-2D eyinkimbinkimbi futhi kwesinye isikhathi i-3Dbobubi.

Ukuhlanganisa amakhono we-CNC kulayini wokusika kuvumela:

- Ukusika ukwakheka:Ukukhiqiza ngokwesikobobubingokupakisha (UkuzivikelaNge-elekthronikhi, izinto zokusebenza), izinto zokwakha, izibonakaliso, noma ama-props ngqo kusukaAmabhulokhi e-EPSnoma amashidi aminyene ngaphakathi kokugeleza okuzenzakalelayo.

- Okuhlukahlukene:Umugqa owodwa ungashintsha phakathi kokukhiqiza amashidi ajwayelekile kanye nenkimbinkimbibobubi, ukwandisa uhla lwemikhiqizo ongalunikeza.

- I-automation of ukusika okuyinkimbinkimbi:Imisebenzi ebingaba nzima kakhulu noma idle isikhathi ukuze isebenze nge-highukwenza kahle. Le khasiUmshini wokusika we-CNCIngxenye isebenzisa isoftware (njenge-CAD / cam) ukuhumusha imiklamo ibe izindlela eziqondile zokusika.

LelisondelaIngeza olunye ungqimba lwenkimbinkimbi futhi ludinga uhlelo oluyinkimbinkimbi futhi luhlukileuwayaukucushwa (e.g., ama-contour cutters). Kodwa-ke, kumabhizinisi asebenzela izimakethe ezidinga ngokwezifisoAma-Eps Foam Shapes, ukuhlanganisa i-CNCusikeniku-zishintshayoumugqa umele amandla anamandla. Iqhubekela phambili elulaVimba ukusikaendaweni eyiqondilefonyaukuboniswa. Kubalulekile ukuxoxa ngalezi zidingo neumenziUkuthola ukuthi ngabe umugqa ojwayelekile noma i-CNC eyodwa efaka ilungeloisixazululo.

Isithombe esikhulu: Ukuthi umugqa wokusika we-EPS uhlangana kanjani nokukhiqizwa kwakho okugcwele kwe-EPS

Aumugqa oqhubekayo wokuqina we-ePSayisebenzi ngokwahlukana. Kuyisixhumanisi esibalulekile ku-inardUkukhiqizwa kwe-EPSiketanga. Ukuqonda indawo yayo kusiza ukwandisa wonke umsebenzi wokuhamba komsebenzi:

- Ukuphathwa Kwezinto Ezibonakalayo:Ubuhlalu be-EPS banwetshwa kuUmshini we-EPS wangaphambili wandisa.

- Ukuguga:Ubuhlalu obunwetshiwe bugcinwa kuma-silos amakhulu (njengeI-EPS SILO) isikhathi sokuzinza.

- Vimba ukubumba:Ubuhlalu obudala bondliwe kuI-EPS block umshini wokubumba(Mpo, ovundlile, noma ovumayo) lapho kushona khona umusi emabhuloki amakhulu.

- Vimba Ukwelapha / Isitoreji:Kusanda kubunjwaAmabhulokhi e-EPSdinga isikhathi sokwelashwa futhi upholile, uvame ukugcinwa okwesikhashana, okungalawulwa yiI-othomathikhi ye-EPS block conveyor.

- Ukusika:Welaphaamabhlogobathuthwa (kaningi ngokuzenzakalelayo) ku-umugqa oqhubekayo wokuqina we-ePSukuukusikakufiselekayoubungakona-uhlobo. Lesi yisigaba esigxile kuwo.

- Ukuphinda usebenzise kabusha:Trim nama-offcuts kusuka kuumugqa wokusikaaqoqwe futhi acutshungulwe nguUmshini wokuphinda usebenzise kabusha, kuvame ukondla izinto eziphindaphindwayo emuva kwinqubo yokukhiqiza.

- Ukuqeda / Umhlangano (uma kudingeka):Ezinye izinhlelo zokusebenza zingadinga izingcezu ezi-Gluing noma zokuhlalisana.

- Ukupakisha:Imikhiqizo eqediwe ihlanganiswe, isongwe (mhlawumbe isebenzisa iUmshini wokupakisha we-EPS), futhi ilungiselelwe ukuthunyelwa.

Ushintsho olubushelelezi phakathi kwalezi zigaba lubalulekile kwisitshalo esipheleleikhono lokwenza. Le khasiumugqa oqhubekayo wokuqina we-ePSIdlala indima ebaluleke kakhulu ngokuthatha okukhulu, okuyi-cumbersomeamabhlogokusuka esigabeni sokubumba futhi uziguqule kahle zibe yimikhiqizo ephathekayo, enosayizi ngokuqondile isilungele isinyathelo esilandelayo noma okokugcinaukufaka ndawonye. Ukuqinisekisaokukhiqizayeumugqa wokusika we-epsQondanisa okukhishwayo kwemishini yokubumba evinjiwe kanye nezidingo zezinqubo ezansize zibalulekile ekulinganiseni futhi zisebenza kahleumkhiqizoFlow ku-EPSimboni, ikakhulukaziukwakhana-ukuwowaphaImikhakha isebenzisastyrofoamizinto zokwakha.

Ukuthathwa kokhiye kwebhizinisi lakho le-EPS:

- Ukusebenza kahle yiNkosi:Aumugqa oqhubekayo wokuqina we-ePSKukhulisa kakhulu ukukhishwa futhi kunciphisa izindleko zabasebenzi kuqhathaniswa nezindlela zezandla.

- Izindaba zokunemba: Ucingo olushisayoUbuchwepheshe obuhlanganiswe ne-automation rosest beletha okungaguquki, okunembile okuphezuluukusikeka, ethuthukisa ikhwalithi yomkhiqizo nokunciphisa imfucuza.

- I-automation inciphisa umthwalo:Ezenzakalelayo ezenzakalelayousikeniInqubo yenza ngcono ukuphepha, iqinisekisa ukungaguquguquki, futhi yenza lula ukusebenza.

- Izakhi zisebenza ngokubambisana:Ikhwalithi ephezuluumugqa wokusika we-epskuncike ezingxenyeni ezihlanganiswe kahle: ama-conveyors, iziteshi zokusika (-vundlile/-mile thwi), izilawuli, kanye nokususa imfucuza / ukugcwala.

- Khetha umlingani wakho ngokucophelela:Khetha aumenziNgobuchwepheshe ngaphakathiImishini ye-EPS, ukwesekwa okuqinile, izingxenye ezisele ukutholakala, kanye nokugxila kwikhwalithi, njengemishini ye-Youli.

- Isondlo asikwazi ukuxoxisana: Ukulungiswa okujwayelekileiqinisekisa ubude obude, ukuthembeka, kanyeukwenza kahlekokutshalwa kwemali kwakho.

- Ukuhlanganiswa kubalulekile:Qondisisa ukuthi kanjaniumugqa wokusika we-epskufanelana ngaphakathi kwakho konkeumkhiqizoUkugeleza ukuze wandise isitshalo esipheleleikhono lokwenza. Cabanga ngezinketho ezithuthukile ezifanaUmshini wokusika we-CNCukuhlanganiswa uma kuyinkimbinkimbibobubiziyadingeka.

Ukutshala imali kuumugqa ozenzakalelayo wokusika we-EPSukunyakaza kwamasu kuthuthukisa-akhoI-Eps FoamAmakhono okukhiqiza, ukukhuphulaikhono lokwenza, futhi ulondoloze umphetho wokuncintisana ekufuneniimboni.

Isikhathi sePosi: 04-14-2025