In recent years, the construction and packaging industries have witnessed a surge in the use of Expanded Polystyrene (EPS) blocks, a versatile material known for its lightweight, insulating properties, and durability. Central to the production of these blocks is the EPS block machine, a sophisticated piece of equipment designed to create EPS blocks with precision and efficiency. But what exactly is an EPS block machine, and why is it becoming increasingly important in today’s industrial landscape?

Understanding the EPS Block Machine

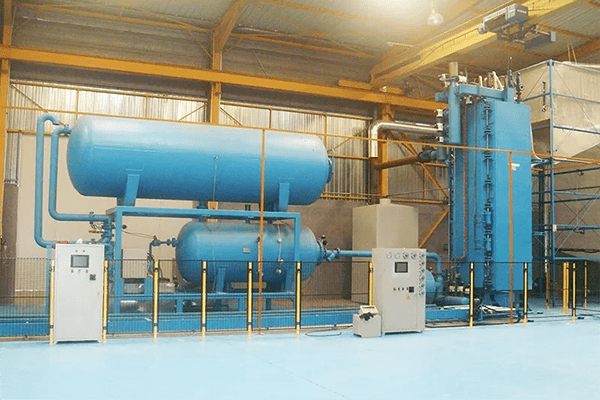

An EPS block machine is a specialized piece of machinery used to produce EPS blocks, which are made from expanded polystyrene, a type of plastic that is expanded into a foam-like material. The machine operates by expanding polystyrene beads and then molding them into blocks of various sizes and densities, depending on the specific requirements. The process typically involves several stages, including pre-expansion, aging, molding, and cutting.

Key Components and Functions

- Pre-expander: This component is responsible for expanding the raw polystyrene beads. The beads are subjected to steam, causing them to expand up to 40 times their original size. The degree of expansion can be adjusted based on the desired density of the final product.

- Aging Silo: After pre-expansion, the expanded beads are stored in an aging silo. This step allows the beads to stabilize and release any remaining pentane gas, which is a by-product of the expansion process. Aging also ensures that the beads are ready for the molding process.

- Block Molding Machine: In this stage, the aged beads are fed into a block molding machine, where they are fused under pressure and heat to form large blocks. The size and shape of the block can be customized according to the mold used in the machine.

- Cutting Machine: Once the blocks are formed, they are transferred to a cutting machine where they are sliced into the desired shapes and sizes. This stage is crucial for ensuring that the EPS blocks meet the specifications required for their intended application.

Applications and Benefits

EPS blocks produced by an EPS block machine are widely used in various industries, primarily in construction and packaging. In construction, EPS blocks are favored for their thermal insulation properties, lightweight nature, and ease of installation. They are often used in the creation of insulated concrete forms (ICFs), roofing, and wall insulation. The packaging industry utilizes EPS blocks for their shock-absorbing qualities, which make them ideal for protecting fragile items during transportation.

The benefits of using an EPS block machine are numerous. First and foremost, the machine allows for the efficient production of EPS blocks, reducing waste and optimizing material usage. The ability to control the density and size of the blocks ensures that manufacturers can produce blocks that meet specific needs, whether for high-strength construction applications or lightweight packaging materials. Additionally, the automation of the production process reduces labor costs and increases overall productivity.

Environmental Considerations

While EPS blocks offer many advantages, there are also environmental considerations to take into account. Polystyrene is a type of plastic, and its production and disposal have been the subject of environmental scrutiny. However, advancements in recycling technologies have made it possible to recycle EPS blocks, reducing the environmental impact. Many EPS block machines are now designed with sustainability in mind, incorporating features that minimize waste and energy consumption.

Conclusion

The EPS block machine plays a pivotal role in the production of EPS blocks, a material that has become indispensable in both the construction and packaging industries. By understanding the components and functions of these machines, as well as their applications and benefits, it is clear that EPS block machines are crucial to modern manufacturing processes. As technology continues to evolve, we can expect further improvements in the efficiency and environmental impact of EPS block production, solidifying their place in a sustainable future.

Post time: 08-24-2024