If you are in the business of manufacturing insulation or packaging, you know that the block is just the beginning. The real value comes from how you slice, shape, and finish that material. Whether you are dealing with Expanded Polystyrene (EPS) or XPS foam, the difference between a profitable run and a waste-filled nightmare often comes down to one thing: your foam cutting machine.

This article explores the world of CNC foam cutting. We will dive deep into hot wire foam technology, explore the capabilities of 3D shaping, and discuss why the right machinery—from a slabber to a complex downcutter—is the backbone of a successful factory. We aren’t just talking about cutting; we are talking about precision, reliability, and maximizing your Return on Investment (ROI).

What Makes a CNC Foam Cutting Machine the Heart of Your EPS Plant?

When you look at a raw foam block, you see potential. But to unlock that potential, you need precision. A CNC foam cutting machine is not just a tool; it is the architect of your production line. Unlike manual methods, CNC foam cutting utilizes computer numerical control to guide the cutter with microscopic accuracy. This means every sheet, every cornice, and every pipe insulation segment is identical to the last.

For factory owners, this consistency is money. CNC machines eliminate human error. When you use a hot wire foam cutter integrated with CNC technology, you ensure that your polystyrene blocks are processed with minimal waste. The wire moves through the material like a ghost, leaving a smooth surface that often requires no further finishing.

Furthermore, modern CNC foam cutting machines are designed for speed. In the insulation game, volume matters. You need a machine that can handle high throughput without sacrificing quality. Whether you are cutting huge foam slabs for construction panels or intricate shapes for packaging, the cutting speed and accuracy of your equipment dictate your daily output.

How Does Hot Wire Foam Technology Actually Work?

You might wonder, why use a hot wire instead of a saw? The answer lies in the physics of foam. A hot wire foam cutter uses a thin, electrically heated wire—typically made of stainless steel or Nichrome—to vaporize the material just ahead of contact. This results in a "cut" that is actually a melt. It is clean, dust-free, and sealed.

The temperature of the cutting wire is a critical parameter. If it is too hot, you get a wide kerf and melted edges. If it is too cool, the wire drags, causing the wire to snap or the foam to tear. Our machines allow you to control these settings with precision, ensuring an optimal cut every time.

Hot wire CNC systems are particularly effective for EPS foam and XPS. The radiant heat ensures that the cutter creates smooth faces, which is essential for external wall insulation systems where surface bonding is key. This technology turns a rough foam block into a high-value product instantly.

Why Should You Choose a 3D CNC Machine for Complex Shapes?

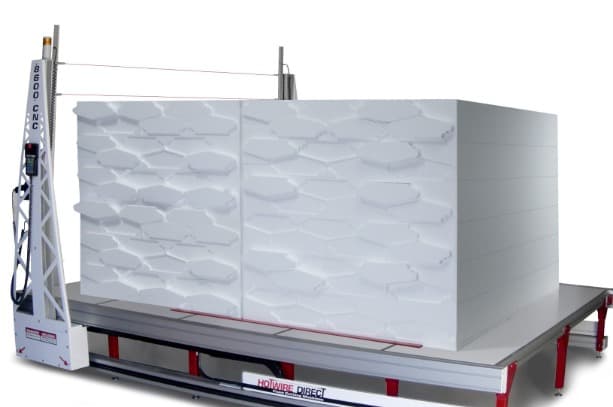

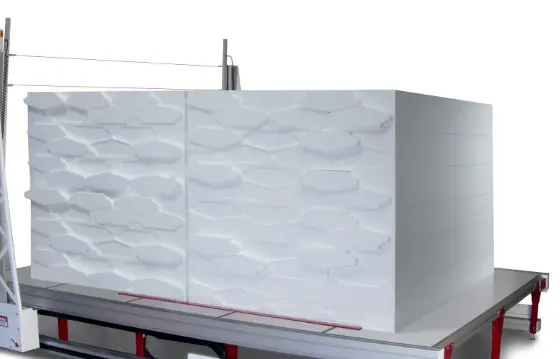

The market is shifting. Simple flat sheets are great, but the high margins are often in architectural shapes and custom packaging. This is where 3D CNC capabilities come into play. A standard foam cutting machine might move on two axes (X and Y), but a 3D capable machine adds depth to your production.

Imagine producing complex columns, twisted pillars, or custom movie props. With 3D software and a 4-axis hot wire CNC foam cutting setup, you can rotate the foam or the wire to create geometries that were previously impossible.

These wire machines allow you to enter the creative market. Sign shops and construction firms love 3D elements. By investing in a machine that handles complicated shape designs, you future-proof your business. You aren’t just selling insulation; you are selling design freedom.

How Do Downcutters and Slabbers Improve Efficiency?

In a high-volume factory, you have different needs for different stages of production. A slabber is a specialized foam cutting machine designed to slice large blocks into horizontal sheets. It often uses multiple wires simultaneously. Think of an egg slicer, but for a massive block of polystyrene foam. This is your workhorse for producing insulation panels.

On the other hand, a downcutter (or vertical cutter) trims the sides and cuts the block to length. When you combine these into a fully automated line, you get our Best Sale EPS Cutting Line. This system integrates the horizontal, vertical, and cross-cutting stations into one seamless flow.

The efficiency gains here are massive. Instead of moving blocks manually between a wire cutter and a trimming station, the conveyor moves the material through the wire machines. This reduces labor costs and increases safety.

What is the Difference Between Hot Wire and Fast Wire?

While hot wire foam cutting is the standard for EPS, some rigid foams or abrasive materials require a different approach. This is where fast wire technology steps in. A fast wire machine uses a rapidly moving abrasive wire—like a band saw, but omnidirectional—to physically grind away the material.

Fast wire is excellent for materials that might melt poorly or require a different surface finish. However, for 90% of polystyrene applications, the hot wire cutter remains superior due to the clean finish and lack of dust.

If you are cutting XPS foam (Extruded Polystyrene), hot wire is still usually the go-to, but the temperature settings must be adjusted because XPS is denser. A high-quality machine will offer the versatility to switch between these modes or adjust the voltage to suit different materials.

How Does the Frame and Build Quality Affect Precision?

You cannot have precision with a flimsy frame. When the wire is moving and the motors are humming, vibrations are the enemy. A robust machine built with a heavy steel frame absorbs these vibrations. If your machine shakes, your wire shakes, and your cut creates "steps" or waves in the foam.

As a manufacturer, we prioritize durability. We use stainless steel components in critical areas to prevent corrosion, especially since steam (moisture) is always present in EPS factories. A long-lasting machine is a machine that keeps its warranty promises.

Look for machines that use high-grade linear guides and ball screws. These components ensure that the cutter moves exactly where the software tells it to, year after year. A stable footprint in your factory translates to stable profits in your bank account.

Why is Software and "Free" Updates Important?

The hardware is the body, but the software is the brain. A CNC foam cutting machine is only as good as the code running it. You need software with free updates or at least a stable platform that doesn’t require a subscription to keep running.

The software should allow you to import standard design files (like DXF) and convert them into cutting wire paths. It needs to handle nesting—arranging shapes on the foam block to minimize waste. Good software helps you utilize every cubic inch of your expanded polystyrene.

Ease of use is vital. Your operators shouldn’t need a degree in computer science to change a parameter. A user-friendly interface on your CNC machines reduces training time and prevents costly mistakes.

What Accessories Should You Consider?

To get the most out of your foam cutting machine, look at optional accessories. A turntable is essential for 3D work (lathe cutting). It spins the block while the wire moves, creating columns and spheres.

Another key accessory is the wire tensioner. As the wire heats up, it expands and gets loose. Automatic tensioners keep the cutting wire tight, ensuring straight cuts.

Don’t forget about safety features. Wire break sensors, emergency stops, and proper fencing are not just "nice to haves"; they are essential for a safe working environment.

Can Recycling Machines Work with Cutting Lines?

Absolutely. Even with the best nesting software, foam cutting creates scrap. Off-cuts, edge trims, and mistakes happen. Instead of throwing this polystyrene away, you should process it.

Integrating a recycling system alongside your CNC EPS Cutting Machine closes the loop. You can crush the waste and re-introduce it into your block molding process (up to a certain percentage). This is where our EPS Recycling Machine shines. It takes the "waste" from your cutter and turns it back into profit.

Why Is Reliability the Ultimate Feature?

When you are supplying a major construction project, you cannot afford downtime. Reliability is the sum of high-quality parts, smart engineering, and good support. If a wire snaps, how fast can you change it? If a motor fails, are parts available?

We build our machinery to run 24/7. We understand that for our clients, especially in regions like Russia and Eastern Europe, the machine needs to be a tank. It needs to withstand voltage fluctuations and heavy dust. That is why we focus on high production capability and rigid construction.

Also, consider the warranty. A manufacturer that stands behind their foam cutting machine with a solid warranty and after-sales support (like video calls or visiting engineers) is worth more than a slightly cheaper upfront price.

Important Things to Remember

- Precision equals Profit: CNC foam cutting eliminates waste and ensures every foam product is identical.

- Know Your Wire: Hot wire is best for EPS and XPS, providing a sealed, smooth finish. Fast wire is for abrasive or specific rigid foams.

- Structure Matters: A heavy steel frame and stainless steel parts prevent vibrations, ensuring accurate cuts and durability.

- Go 3D: Expand your market by using 3D CNC capabilities to create architectural shapes and complicated shape designs.

- Automate the Line: Combine your cutter with a slabber and downcutter in a full line for maximum cutting speed.

- Recycle the Scrap: Use a recycling machine to turn off-cuts from the wire machines back into raw material.

- Check the Software: Ensure your cnc machines come with intuitive software to manage nesting and parameter control easily.

For more information on setting up a complete production facility, check out our EPS Shape Moulding Machine options to complement your cutting capabilities.

Post time: 01-27-2026