If you have ever tried to slice through a block of Styrofoam with a serrated kitchen knife, you know the pain. The squeaking sound, the uneven edges, and the blizzard of white beads covering your floor—it is a mess. Whether you are a factory owner like my client Victor in Russia, or a dedicated hobbyist building a model train landscape, the solution is the same: heat. Finding the best hot wire foam cutter is about understanding how to use a heated element to vaporize foam rather than tearing it.

As a manufacturer of large-scale EPS machinery, I usually deal with automated giants that process tons of material. However, the physics behind a massive CNC machine and a handheld tool are identical. This guide will walk you through everything you need to know to find the right cutter, whether you are looking for a cheap solution for a weekend craft project or a professional setup for architectural prototyping.

What Makes a Hot Wire Foam Cutter the Ultimate Tool?

A hot wire foam cutter is deceptively simple. It uses a thin metal wire—usually Nichrome or stainless steel—heated by an electrical current. When this hot wire touches the foam, it doesn’t just cut; it vaporizes the material upon contact. This seals the cells of the foam, leaving a smooth, square edge that requires zero sanding. Unlike a saw blade which creates dust, a hot wire is clean.

For anyone working with EPS (Expanded Polystyrene) or XPS (Extruded Polystyrene), this tool is indispensable. The best hot wire systems allow for precision that no mechanical blade can match. You can slice thin veneers, create complex curves, or simply size down insulation panels with ease.

When you browse Amazon or check hobby stores, you will see various types of foam cutters. The key is to match the tool to the density of the foam and the intricacy of the cut. A hot wire foam cutter designed for soft floral foam will struggle with high-density rigid insulation.

How to Build or Buy: Is a Proxxon Better Than a DIY Model?

One of the most common questions I hear is whether to buy a branded unit like a Proxxon or to build a DIY version. A Proxxon Thermocut table is a fantastic "middle ground" device. It offers a stable surface, a decent fence, and a reliable transformer. For model building and small architectural work, it is often considered the best option.

However, if you are on a budget or need a specific size (like a very wide bow), building your own can be cheaper. You can construct a simple cutter using a battery, a dimmer switch (as a controller), and a guitar string or Nichrome wire. But be warned: a DIY power supply can be tricky. If you don’t regulate the voltage correctly, the wire can overheat and snap, or run too slow, dragging through the foam.

If you choose to build, ensure your frame is rigid. A shorter wire is easier to keep tight, while a long wire tends to sag when hot, ruining your straight line.

Why Use a Hot Knife for Intricate Carving and Detail?

Sometimes, a wire stretched between two points isn’t enough. You need to carve a 3D shape, like a mountain for a terrain board or a custom prop. This is where the hot knife shines. Resembling a soldering iron with a long, flat blade, a hot knife allows you to plunge directly into the foam block.

It is the perfect tool for freehand carving. You can scoop out material, shape curves, and add texture. The handle should be insulated and comfortable, as you might be holding it for hours. However, a hot knife is slower than a wire cutter. It relies on the heat of a thicker rod, so it takes longer to melt its way through. For fast, straight cuts, stick to a wire; for artistic detail, grab the knife.

How Does a Table and Fence Ensure Perfect Straight Cuts?

If your goal is accuracy—like cutting brick walls for a diorama or slicing foam board for signage—you need a table cutter. Just like a table saw for wood, a foam cutting table supports the material. The most critical component here is the fence.

A sturdy fence allows you to slide the foam past the vertical wire to get a perfectly consistent thickness. If you are making a roadbed for a train layout, you need those slopes and flats to be exact. A handheld bow cutter relies on your steady hand, and human hands wobble. A table setup eliminates that variable.

Many model makers use a foot pedal to activate the heat, allowing them to keep both hands on the foam to hold it steady against the guide. This setup gives you the control to make repeated cuts without variation.

Styrofoam, Insulation, and Foam Board: Handling Materials with a Bow

Different foams react differently to heat. Styrofoam (expanded polystyrene) cuts easily but creates a lot of off-gassing, so ventilation is key. Insulation foam (XPS, usually pink or blue) is denser and cuts beautifully, leaving a very smooth, wax-like surface. Foam board (with paper backing) is tricky; the paper doesn’t melt, so a hot wire isn’t the best hot wire foam cutter choice there—you need a sharp physical knife or a very hot blade that burns through the paper (which can be a fire hazard).

For large sheets of insulation, a handheld bow cutter is often the handy choice. You can clamp a straight edge to the foam sheet and run the bow along it. This is much easier than trying to wrestle a 4×8 foot sheet onto a small table cutter.

Mastering the Temperature: The Importance of the Power Supply and Controller

The difference between a clean cut and a jagged mess is usually temperature. If the temp is too low, you have to force the wire, causing it to bow and creating a curved cut (the "banana" effect). If it’s too high, you melt too much material, losing precision and creating a wide kerf.

You need a variable power supply or controller. This allows you to dial in the exact heat needed for the speed you are cutting. As you cut, the foam cools the wire. A good transformer maintains constant current. Whether you use a Proxon or a custom rig, being able to vary the heat is the mark of a professional setup.

Model Building and Terrain: Creating the Perfect Result

In model building, especially for train enthusiasts, the foam wire cutter is the primary earth-moving tool. You stack layers of foam sheet to build elevation, then use a cutter to shape the hills and valleys.

For terrain, you often want a slightly uneven surface. A handheld wire cutter with a flexible wire allows you to "sculpt" the land. However, for the roadbed itself, you switch back to the table and fence to ensure the tracks lay flat. Using glue specifically designed for foam is also crucial, as standard super glues will melt your work.

Accessories and Replacement Parts: Keeping Your Foam Wire Cutter Alive

Every cutter needs maintenance. The wire will eventually break. It is smart to keep replacement wire on hand. Nichrome wire is the standard because it withstands high heat without oxidizing too quickly.

Other useful accessories include a circle cutting guide (for making columns or round bases) and a foot switch. A clamp system to hold the fence rigid is also vital. If you are doing a lot of work, a cleaner brush for the wire is handy; melted plastic residue can build up on the wire, causing it to smoke and cut unevenly.

Max Efficiency: When to Upgrade to a Professional Machine

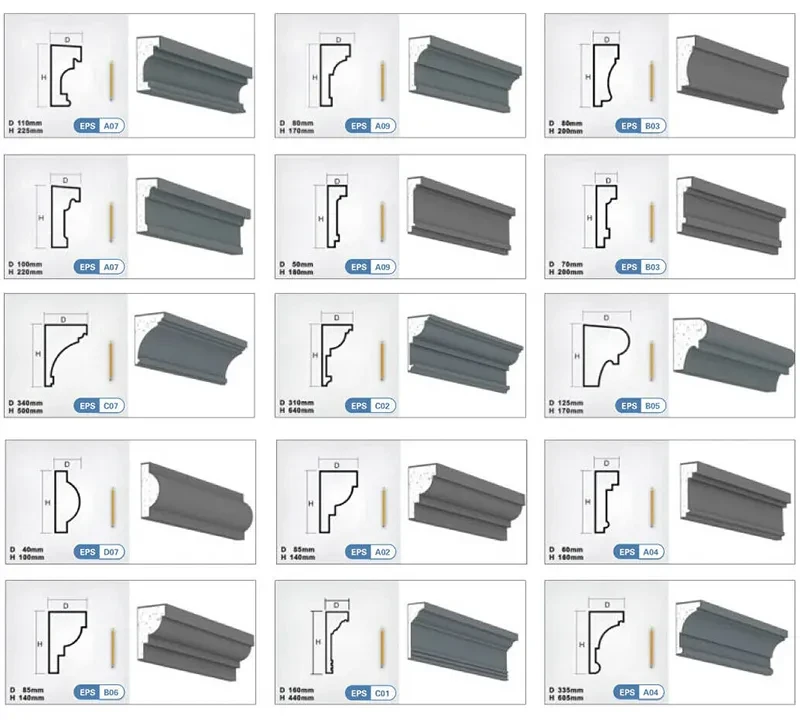

There comes a point where a handheld tool or a small Proxxon table isn’t enough. If you are producing thousands of packaging inserts, or cutting large cornice moldings for construction, you need a machine.

Industrial CNC EPS Cutting Machines are the big brothers of the hobby table. They use computer control to move the wire on multiple axes simultaneously. They can handle massive blocks of foam—produced by machines like our Horizontal EPS Block Machine—and slice them into intricate profiles with zero manual labor. If you find yourself spending all day cutting and the result is still inconsistent, it might be time to look at automation.

Furthermore, in a factory setting, waste management becomes critical. You can’t just sweep up. You need an EPS Recycling Machine to crush and compact the scrap, keeping your facility clean and efficient.

Summary of Key Points

- Heat is Key: A hot wire foam cutter creates a sealed, dust-free edge that blades cannot match.

- Choose the Right Tool: Use a table with a fence for straight, geometric cuts, and a hot knife or handheld bow for freeform carving.

- Control the Temp: A variable controller or power supply is essential to prevent wire drag or excessive melting.

- Material Matters: Styrofoam and Insulation (XPS) cut beautifully, but avoid paper-faced foam board with hot wires.

- Scale Up: For hobby work, a Proxxon or DIY build is fine; for volume production, invest in a CNC machine.

- Safety First: Always ventilate your workspace to avoid fumes, and watch out for the hot element!

Whether you are building a miniature world or insulating a skyscraper, the right cutter makes all the difference.

Post time: 02-05-2026