Welcome to the world of Expanded Polystyrene (EPS)! If you’re in the business of manufacturing, packaging, or construction, you already know the value of this incredible material. But have you ever wondered about the intricate journey from a tiny polystyrene bead to a finished EPS foam product? As a manufacturer of EPS machinery for decades, I’m Allen, and I’ve seen firsthand how a deep understanding of the EPS molding process can transform a business. This comprehensive guide is for leaders like you—company owners and procurement officers who need to make informed decisions. We’ll break down the entire process, step-by-step, to help you optimize production, ensure quality, and maximize profitability.

What Exactly is Expanded Polystyrene (EPS) and Why Is It So Popular?

Expanded Polystyrene, commonly known as EPS, is a rigid, tough, closed-cell foam material. You’ve seen it everywhere: as protective packaging for fragile items, as insulation panels in buildings, and even in bicycle helmets. But what gives this lightweight material its remarkable properties? The secret lies in its structure. EPS is approximately 98% air, trapped within a matrix of 2% polystyrene. This unique composition is what gives EPS foam its signature benefits.

The properties of EPS are what make it a go-to material for a wide range of applications. Its closed-cell structure provides excellent thermal insulation, making it ideal for keeping homes warm and products cold. Its low weight reduces transportation costs, and its exceptional shock-absorbing capabilities make it perfect for protective packaging. Here’s a quick breakdown of its key attributes:

- Lightweight: With a composition that is mostly air, EPS is incredibly easy to handle and transport.

- Insulation Properties: The trapped air within the closed cell structure makes EPS a poor conductor of heat, giving it superior thermal insulation properties.

- Durability & Strength: Despite its low weight, EPS has a high compressive strength, allowing it to protect heavy or fragile items effectively.

- Moisture Resistance: EPS is non-hygroscopic, meaning it does not readily absorb moisture from the atmosphere.

- Cost-Effectiveness: Compared to other materials with similar properties, EPS is remarkably affordable to produce, a key factor for any business owner.

How Does the EPS Moulding Process Begin? A Look at Raw Materials

The entire EPS moulding process starts with a simple-looking but complex raw material: tiny, translucent polystyrene beads. These beads, typically 0.5 to 1.3 mm in diameter, are the foundation of every EPS foam product. However, they hold a secret ingredient that makes the magic of expansion possible: a blowing agent.

This blowing agent is usually pentane, a liquid hydrocarbon, which is impregnated into the polystyrene beads during their production. The pentane is dormant within the raw EPS bead until it’s activated by heat. When steam is applied in the first stage of production, the pentane expands, causing the solid polystyrene bead to soften and inflate, much like popcorn. This process is known as pre-expansion. The quality of this raw material is paramount; inconsistent bead size or pentane content can lead to variations in the density of the EPS and affect the quality of the final product. That’s why sourcing high-quality raw material is just as important as having a reliable EPS machine.

What is the Critical First Step: The EPS Pre-Expansion Process?

Pre-expansion is arguably the most crucial stage in the entire EPS molding process. It is here that the final density and fundamental characteristics of the EPS foam are determined. During this step, the raw polystyrene beads are fed into a machine called a pre-expander, where they are exposed to controlled steam. The heat from the steam causes two things to happen simultaneously: it softens the polymer, and it vaporizes the pentane trapped inside each bead.

As the pentane turns into a gas, it creates internal pressure that causes the beads to expand significantly—up to 50 times their original volume! The amount of steam and the duration of the exposure are meticulously controlled to achieve a specific target density. Lower density foam requires more expansion and results in a lighter product, often used for void fill packaging. Higher density foam is less expanded, resulting in a stronger, more rigid product suitable for construction insulation or durable packaging. A modern EPS Pre-expander machine uses precise control systems to ensure that millions of beads are expanded uniformly, which is essential for achieving a consistent final product. Without this control, the structural integrity of the EPS foam would be compromised.

After Expansion, What Happens During the Aging and Stabilizing Phase?

Once the polystyrene beads are expanded, they are not immediately ready for the mould. The pre-expanded beads are hot, moist, and dimensionally unstable. As they cool, the pentane gas inside them also cools and condenses, creating a partial vacuum within each bead. If you were to try and mold them at this stage, the beads would be too soft and could collapse under pressure.

To solve this, the expanded beads are pneumatically conveyed into large, open-mesh silos for an "aging" or "maturing" period. This typically lasts from 6 to 12 hours. During this time, air slowly diffuses into the beads, equalizing the internal pressure with the atmospheric pressure outside. This process allows the beads to stabilize, cool down, and gain the mechanical strength needed to withstand the pressures of the final molding process. This aging step is vital for ensuring that the beads fuse together properly in the mold cavity and that the finished EPS product has the required strength and stability.

What Are the Two Main Types of EPS Molding Processes?

After the pre-expanded beads have been aged and stabilized, the EPS moulding process can proceed down one of two primary paths, depending on the desired final product. These two methods are Block Moulding and Shape Moulding. Each uses a different type of molding machine and serves a distinct purpose in the industry.

| Feature | Block Moulding | Shape Moulding |

|---|---|---|

| Purpose | Creates large, rectangular blocks of EPS foam. | Creates custom, complex-shaped EPS foam products. |

| Process | Beads fill a large mold, fuse into a single block. | Beads fill a custom-designed, often intricate, mold. |

| Final Product | Sheets for insulation, geofoam blocks, packaging supports. | Protective packaging, helmets, cooler boxes, automotive parts. |

| Machinery | EPS Block Moulding Machine. | EPS Shape Moulding Machine. |

| Flexibility | Low (produces one shape), but blocks can be cut. | High (produces specific, detailed shapes). |

Understanding the difference is critical when planning a production line. A company focused on construction insulation will invest heavily in block moulding technology, whereas a business that serves the electronics or automotive industries will need the precision of shape moulding machines.

How Does an EPS Block Moulding Machine Create Large Foam Blocks?

The goal of block moulding is to produce large blocks of EPS, which can then be cut into sheets, boards, or custom shapes. The process involves a large rectangular mold, often several meters long. The aged, pre-expanded beads are blown into this massive mold cavity until it is completely full.

Once the mold is sealed, the fusion process begins. Steam is injected through small vents located all over the inner surfaces of the mold. This steam heats the beads again, causing them to soften and expand a second time. Since they are now confined within the fixed volume of the mold, this secondary expansion forces the beads to press against each other and fuse together, forming one solid, homogenous block of EPS foam. After the steam cycle, the mold is cooled with water sprays or a vacuum system to solidify the block. The cooling process is crucial for stabilizing the block and preventing it from warping after ejection. Finally, the mold door opens, and the large block is pushed out onto a conveyor. This entire process is highly automated with a modern Horizontal EPS Block Machine, allowing for high-volume production of EPS foam blocks.

What is EPS Shape Moulding and How Does It Create Custom Designs?

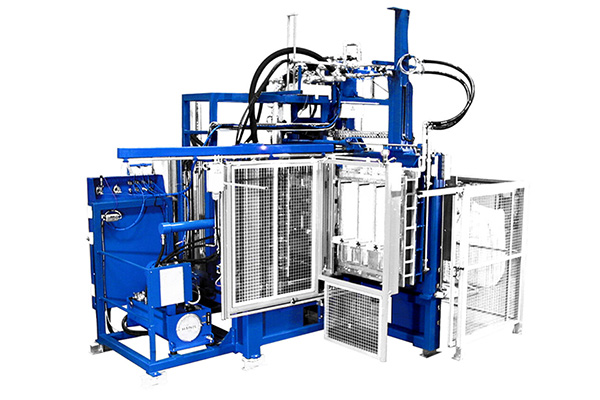

While block moulding is perfect for high-volume sheets, shape moulding is where the versatility of EPS truly shines. This process is used to create custom-designed products with intricate detailing, such as packaging for a new television, components for automotive bumpers, or insulated fish boxes. The core principle is the same as block moulding—using steam to fuse pre-expanded beads—but the execution is far more precise.

In shape moulding, a custom-made aluminum mold is used. This mold is a negative of the desired final product. The aged beads fill the mold cavity through fill guns, ensuring even distribution even in complex shapes. Steam is then applied, and the beads expand further and fuse together to perfectly replicate the shape of the mold. The EPS Shape Moulding Machine controls the steam, water cooling, and air pressure with extreme precision. After a short cooling cycle, the mold opens, and the final form—a perfectly molded foam product—is ejected, ready for use. This process allows for the mass production of complex parts with remarkable consistency and cost-effectiveness.

What Key Factors Ensure a High-Quality EPS Molding Process?

Achieving a high-quality, consistent EPS product isn’t just about having a molding machine; it’s about controlling every variable in the moulding process. As a machine manufacturer, I’ve worked with hundreds of clients, and the most successful ones are those who pay close attention to the details.

Here are the critical factors that determine the quality of the final EPS foam:

- Raw Material Quality: The journey begins with the polystyrene beads. Consistent bead size and pentane content are non-negotiable for predictable expansion and density.

- Steam Quality & Pressure: The steam used for expansion and fusion must be dry and delivered at a consistent pressure. Wet steam can lead to moisture pockets in the final product, compromising its insulation properties and strength.

- Pre-Expansion Control: As discussed, this stage sets the density. A reliable eps machine with precise controls is essential to hit the target density every single time.

- Aging Time: Rushing the aging process is a common mistake. Insufficient aging leads to poor fusion in the mold, resulting in a weak and brittle product.

- Mold Design and Condition: The mold itself is critical. For shape moulding, the mold must be well-designed with proper venting to allow steam to penetrate evenly and air to escape. The mold must also be clean to ensure a smooth surface finish on the product.

- Cooling Cycle: Proper cooling is essential to solidify the product and prevent post-molding warping or shrinkage. A vacuum-assisted cooling system can significantly speed up this step and improve dimensional stability.

What Happens to EPS After Moulding? The Finishing and Recycling Stages

The EPS moulding process doesn’t end when the product is ejected from the mold. For blocks, the next step is typically cutting. The large blocks of EPS are moved to a cutting line where hot wires slice them into sheets of various thicknesses. These sheets are then ready for use as insulation or for further fabrication. For molded foam products from shape moulding, they may need some minor finishing, but are often ready for packing and shipping immediately.

One of the most important post-moulding considerations is recycling. EPS is 100% recyclable, and managing scrap is both environmentally responsible and economically smart. Scrap from cutting or rejected parts can be ground up and mixed back in with virgin beads to create new EPS products. For external EPS waste, specialized recycling machines play a key role. An EPS Recycling Machine EPS Crusher + De-duster+ Dust compactor can process this waste efficiently. The foam is compacted or melted down into dense blocks or ingots, which dramatically reduces its volume and makes it economical to transport to recycling facilities where it can be turned back into polystyrene plastic for new uses.

How Do You Choose the Right EPS Moulding Machines for Your Factory?

For a business owner like Mark Thompson in the USA, purchasing an EPS molding machine is a significant investment. The decision goes beyond just the initial price. Based on my experience exporting to North America and Europe, here are the key concerns that should be at the forefront of your purchasing process:

- Performance and Reliability: The machine must perform consistently day in and day out. Look for manufacturers who use high-quality components from reputable brands (e.g., Siemens, Schneider). Ask about the machine’s frame construction—a robust, stress-relieved steel frame is a sign of durability.

- Automation Level: Labor costs are a significant factor in Western countries. A high level of automation, from material feeding to product ejection, reduces manual labor, minimizes human error, and increases production efficiency.

- Energy Consumption: Steam and electricity are major operational costs. Modern EPS moulding machines are designed with energy-saving features, such as superior insulation on the steam chamber and efficient vacuum systems, which can lead to substantial long-term savings.

- After-Sales Service and Support: This is where many overseas suppliers fall short. What happens when you need a spare part or technical support? A reliable supplier has a system in place for remote diagnostics, readily available spare parts, and clear communication channels. Ask about their support structure before you buy.

- Safety and Certifications: Ensure the machine complies with international safety standards and has the necessary certifications, such as CE marking for the European market. Safety features like emergency stops and interlock systems are non-negotiable.

Choosing the right machinery partner is about finding a company that understands your business needs, addresses your pain points, and stands behind their product for the long haul.

Key Takeaways

The EPS moulding process is a fascinating and precise science. To ensure success, remember these key points:

- It all starts with quality: The entire process, from the raw material to the final foam product, depends on high-quality inputs and controls at every stage.

- Pre-expansion is critical: This initial step determines the final density and is the foundation for the product’s physical properties.

- Choose the right molding process: Understand the difference between block and shape moulding to align your machinery with your market needs.

- Control the variables: Steam, cooling, and aging time are not just steps; they are critical variables that must be meticulously managed for consistent results.

- Invest in a reliable partner, not just a machine: Your machinery supplier should provide not only a durable, efficient molding machine but also the long-term support you need to keep your production running smoothly.

Post time: 08-18-2025