Hello, I’m Allen. For over twenty years, I’ve been immersed in the world of foam machinery, manufacturing the equipment that powers businesses across the globe. At countless exhibitions, I’ve spoken with business owners like Mark Thompson from the USA—sharp, decisive leaders who need to understand their materials inside and out to stay ahead. The one material that consistently forms the backbone of their operations is Expanded Polystyrene, or EPS. It’s the white, lightweight foam we all recognize, yet its incredible versatility and robust properties are often overlooked. This guide is my insider’s look into what EPS truly is, how it’s made, and why this remarkable, versatile material is a cornerstone of modern industry.

What Exactly is Expanded Polystyrene (EPS) and How is it Made?

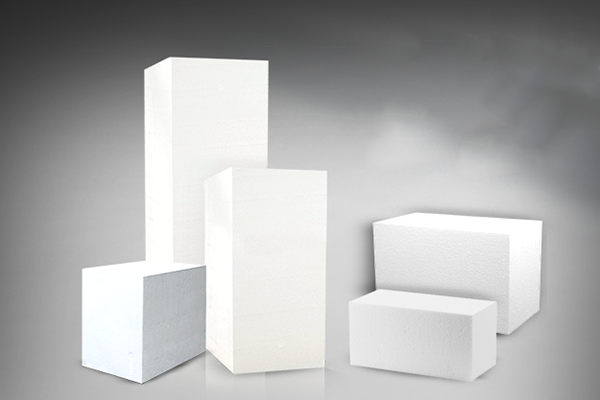

At its core, Expanded Polystyrene (EPS) is a rigid, cellular plastic foam material derived from styrene monomer. It’s the familiar white foam used for everything from a coffee cup to protective packaging for a new television. But what makes EPS so unique is its structure. It consists of thousands of tiny, individual spherical beads fused together. What you might not realize is that EPS is composed of about 98% air, making it an incredibly efficient material. This composition is the secret to many of its most valued properties.

The manufacturing process for EPS is a fascinating example of polymer science. The journey starts with tiny, hard beads of polystyrene resin. These solid beads of polystyrene contain a small amount of a blowing agent, typically a hydrocarbon like pentane. When these beads are exposed to steam, the pentane expands, causing the polystyrene bead to swell up to 40 times its original size. These expanded beads are then allowed to cool and stabilize before being molded. In a large mold, more steam is applied, causing a second expansion that fuses the individual beads together into a large, solid block of EPS foam. This block can then be cut into sheets or custom shapes, creating the EPS products we use every day.

What Makes EPS Such a Lightweight Yet Strong Material?

The first thing anyone notices about EPS is how incredibly lightweight it is. As mentioned, an EPS product is approximately 98% air, trapped within a closed-cell polymer matrix. This means a cubic meter of EPS can weigh as little as 10-15 kilograms, depending on its density. This property is a massive advantage in both packaging and construction. For packaging applications, it adds very little weight to packaging, which significantly reduces shipping costs. In construction, using lightweight foam components reduces the overall load on a building’s structure and makes them easier and safer for workers to handle on-site.

Despite being mostly air, the strength of EPS is remarkable, particularly its compressive strength. This strength comes from its unique closed-cell structure. Each tiny bead of EPS acts like a small, strong pocket of air. When these are all fused together, they form a rigid block that can support significant weight without deforming. The final compressive strength is directly related to the density of the EPS foam. By controlling the expansion process, manufacturers can produce EPS in a wide range of densities to meet specific performance requirements, from soft, flexible foam for fragile items to high compressive strength blocks used in civil engineering projects.

How Do the Thermal Properties of EPS Make it an Excellent Insulation Material?

One of the most valuable characteristics of Expanded Polystyrene is its exceptional ability to insulate. The reason EPS is such a fantastic insulation material comes back to its structure: all that trapped air. Air is a poor conductor of heat, and by trapping it in countless tiny pockets, EPS dramatically slows down the transfer of thermal energy. This property, known as low thermal conductivity, is what makes EPS a cornerstone of the energy-efficient building movement. When used as insulation, EPS helps keep buildings warm in the winter and cool in the summer, reducing the need for heating and air conditioning and lowering energy bills.

The thermal properties and thermal performance of EPS foam are stable and predictable. It provides a consistent R-value (a measure of thermal resistance) for the life of the building. This makes EPS a reliable and cost-effective choice for all types of insulation applications. You will find EPS being used in walls, roofs, and floors. It is particularly effective in systems like External Wall Insulation (EWI), under-slab insulation, and as a component in structural insulated panels (SIPs). The versatility of EPS means it can be used to insulate nearly any part of a building envelope, making it a go-to material for architects and builders aiming to create comfortable, energy-efficient spaces.

Is EPS Foam the Same as Extruded Polystyrene (XPS)?

This is a question I get all the time, and it’s an important distinction for anyone in the industry. While both EPS and Extruded Polystyrene (XPS) are rigid foam insulation materials made from polystyrene, their manufacturing processes and final properties are quite different. As we’ve discussed, EPS is manufactured by expanding spherical beads in a mold. This process creates a block of fused, closed-cell beads.

On the other hand, XPS is manufactured in a continuous extrusion process that produces a homogeneous, closed-cell structure. In this method, polystyrene crystals are melted along with special additives. A blowing agent is then injected, and the mixture is forced through a die, where it expands into the final shape of the XPS foam board. This process gives XPS its characteristic smooth, uniform surface and a more consistent cell structure compared to the beaded appearance of EPS.

Here’s a quick comparison:

| Feature | Expanded Polystyrene (EPS) | Extruded Polystyrene (XPS) |

|---|---|---|

| Manufacturing | Expanding and fusing beads in a mold. | Continuous extrusion process. |

| Appearance | White, made of visible fused beads. | Typically colored (blue, pink, green), smooth surface. |

| Water Resistance | Good, but can absorb some water between beads. | Excellent, very low water absorption. |

| Permeability | Semi-permeable, allowing some water vapor to pass. | Very low permeability ("vapor barrier"). |

| Cost | Generally more cost-effective. | Typically more expensive. |

| Environmental | Uses pentane, a low-impact blowing agent. | Historically used CFCs or HFCs; now shifting to better agents. |

While XPS may offer slightly better moisture resistance in certain applications, EPS provides superior value and design flexibility, making it the more popular choice for a vast range of insulation needs.

What are the Most Common Applications for EPS Foam?

The versatility of EPS is truly astounding. Because its properties can be tailored by adjusting its density, this foam material produced from polystyrene resin is used across a huge number of industries. It’s a true multi-purpose material.

In the construction industry, EPS is a superstar. It’s widely used for:

- Thermal Insulation: This is its primary role. EPS insulation is used in walls, roofs, and floors to create highly energy-efficient buildings. It’s also a key component in underfloor heating systems and beam and block construction.

- Geofoam: Large, lightweight blocks of EPS are used as a structural fill in civil engineering projects, such as building road or rail embankments on soft ground or creating stadium seating.

- Architectural Shapes: The ease with which EPS can be cut and shaped makes it perfect for creating decorative moldings, columns, and other architectural features.

Beyond construction, EPS is widely used in packaging applications. Its excellent shock-absorbing qualities and lightweight nature make it the ideal material for protecting fragile items during shipping, from delicate electronics to major appliances. You’ll also find EPS used in horticulture as seed trays and for soil aeration, in marine applications for flotation, and even in safety equipment like bicycle helmets. The list of products made from EPS is nearly endless.

How Does the EPS Manufacturing Process Work, from Bead to Block?

For a business owner like Mark, understanding how his core material is made is crucial. The production of EPS is a two-stage process that transforms tiny resin beads into massive blocks of foam. It all starts with the raw material: polystyrene beads. These solid beads of polystyrene, which look like small sugar crystals, are manufactured from polystyrene resin, a petroleum by-product derived from natural gas.

The first stage is called "pre-expansion." The raw bead is fed into a vessel where steam and a blowing agent (typically pentane) are applied. The heat from the steam softens the polystyrene and causes the pentane to vaporize, creating bubbles that expand the bead to many times its original size. After this step, the now-expanded bead is soft and unstable. The beads are stored in large, open-air silos for 6 to 48 hours. This "aging" period allows the beads to cool, harden, and reach a stable pressure equilibrium.

The second stage is "molding." The aged, expanded beads are transferred into a large block mold. More steam is injected, applying heat and pressure. This causes a final expansion, forcing the beads to press against each other and fuse together into a single, massive EPS block. After a short cooling period, the block is ejected from the mold and is ready for cutting. This entire process, from raw bead to finished block, is something we specialize in, providing robust EPS Block Moulding Machines that are the heart of any EPS production facility.

Why is the Compressive Strength of EPS So Important for Construction?

When we talk about construction applications for EPS, we’re often talking about situations where the material is under load. This is where compressive strength becomes a critical performance metric. Compressive strength is the ability of a material to resist forces that are trying to crush it. For a material that is 98% air, EPS boasts an impressive high compressive strength, which can be precisely controlled by its density. A higher density EPS block has thicker cell walls, giving it greater compressive resistance.

This property is what allows EPS to be used in demanding, load-bearing applications. For example, when EPS insulation is placed beneath a concrete floor slab, it must be strong enough to support the weight of the concrete and everything that will eventually be on that floor—furniture, equipment, people—without being crushed. The same is true when EPS is used as Geofoam. It can support the immense weight of roadways, airport runways, and building foundations.

The ability to engineer the strength of EPS makes it a highly reliable material used in construction. Engineers can specify the exact density and compressive strength required for a project, ensuring that the EPS product will perform safely and effectively for the life of the structure. It’s this combination of being lightweight yet strong that makes EPS a truly innovative engineering material.

Is EPS a Sustainable and Recyclable Material?

There is a common misconception that EPS is bad for the environment. The truth is, EPS is a surprisingly sustainable and recyclable material. First, EPS is made of a single polymer (polystyrene), which makes it easy to recycle. It is not a mixture of different plastics, which can be difficult to separate. In fact, EPS is 100% recyclable. There is a well-established market for recycled EPS, and many communities have collection points or special programs to recycle EPS foam packaging.

The recycle process is straightforward. The collected EPS is ground up, washed, and then either re-introduced into the EPS manufacturing stream to create new products with recycled content, or it’s melted and extruded into pellets of solid polystyrene. These pellets are then used to manufacture entirely new products like picture frames, park benches, and architectural molding. As a manufacturer of recycling equipment, we see firsthand how a dedicated EPS Recycling Machine can turn waste into a valuable resource, closing the loop on the material’s lifecycle.

Furthermore, the greatest environmental benefit of EPS comes from its primary use: insulation. The amount of energy saved over the lifetime of a building by using EPS insulation is many times greater than the energy used to produce the foam in the first place. EPS contributes significantly to reducing greenhouse gas emissions by creating energy-efficient insulation solutions. It also has a low carbon impact during manufacturing and is produced without the use of harmful CFCs or HFCs, ensuring it doesn’t harm the ozone layer and has good indoor air quality characteristics.

How Stable is EPS? Understanding its Resistance to Water and Chemicals.

For any material used in construction, long-term stability and durability are non-negotiable. EPS excels in this regard. Because it is a closed cell plastic, it has very low water absorption. While XPS is slightly more water-resistant, EPS performs exceptionally well in most conditions. Any water it might absorb is typically held in the tiny channels between the fused beads, not within the beads themselves. This water can easily dry out, and studies have shown that even after prolonged exposure, the thermal properties of EPS are not significantly affected.

EPS is also chemically inert, meaning it does not react with most common substances. It is highly resistant to aqueous solutions of salts and alkalis, which are often present in soil and concrete. This makes it an ideal material for below-ground applications like foundation or sub-slab insulation. It will not rot, decay, or provide nutrient value for mold, mildew, or pests.

The dimensional stability of EPS is also excellent. It is a thermoplastic, so it can be affected by extreme temperatures, but under normal service conditions, it remains very stable. Industry standards, such as ASTM Test Method D2126, confirm that the maximum dimensional change of EPS is very low. This means that once installed, the dimensional change of EPS foam is negligible, ensuring it will continue to provide effective insulation without shrinking or warping for the entire lifespan of the building.

What Does the Future Hold for this Versatile Material?

The future for Expanded Polystyrene looks incredibly bright. As the global focus on energy efficiency and sustainable building practices intensifies, the demand for high-performance insulation materials like EPS will only continue to grow. We are seeing continuous innovation in the EPS industry, with the development of new types of EPS that incorporate graphite or other materials to enhance their thermal properties even further. These advanced EPS products provide a higher R-value per inch, allowing for thinner walls while still meeting stringent energy codes.

The push for a circular economy is also benefiting EPS. As collection and recycling infrastructures improve, the perception of EPS is shifting from a single-use material to a fully recyclable resource. Companies are increasingly looking for ways to incorporate recycled content into their products, and EPS is perfectly suited for this. Innovations in chemical recycling promise to break down post-consumer EPS back into its original styrene monomer, allowing it to be reborn as a virgin-quality material over and over again.

From advanced building materials to smarter, more sustainable packaging, EPS will continue to be the versatile material that engineers, architects, and product designers rely on. Its unique combination of being lightweight, strong, insulating, and recyclable ensures that EPS will remain an essential component of a more efficient and sustainable future.

Key Takeaways About Expanded Polystyrene (EPS)

As we’ve seen, EPS is far more than just a simple foam. It’s a high-performance material with a unique set of properties that make it incredibly valuable across many industries.

- What it is: EPS is a rigid, lightweight foam made from expanded polystyrene beads, consisting of 98% air.

- Key Properties: It offers excellent thermal insulation, high compressive strength relative to its weight, and good moisture resistance.

- Major Applications: It is a dominant material in the construction industry for insulation and in the packaging industry for protecting goods.

- Manufacturing: EPS is manufactured by expanding tiny polystyrene beads with steam and fusing them together in a mold.

- Sustainability: EPS is 100% recyclable and plays a crucial role in reducing energy consumption in buildings, making it an environmentally responsible choice.

Post time: 12-03-2025