As a manufacturer, you know that the right machinery is the cornerstone of your business. It’s the difference between meeting demand and falling behind, between quality products and costly defects. When it comes to producing complex, lightweight, and protective items, the EPS Shape Molding Machine stands out as a critical asset. This article is your comprehensive guide to understanding this powerful equipment. We will delve into the entire molding process, from the raw EPS bead to the final product, and explore why choosing the right machine is a pivotal decision for your company’s growth and profitability. This is for leaders like you, who are decisive and seek both quality and value.

What Exactly is an EPS Shape Molding Machine?

An EPS foam shape molding machine is a specialized piece of equipment designed for one primary purpose: to transform tiny raw polystyrene beads into finished products of virtually any shape. Think of it as the heart of your EPS production line. This is not to be confused with an EPS Block Moulding machine, which creates large blocks of EPS foam that are later cut. Instead, a shape moulding machine uses a specific mould cavity to form intricate, ready-for-use items directly.

The machine controls a precise cycle of steam heating, cooling, and ejection to produce everything from protective packaging for fragile items to components for the construction and automotive industries. These moulding machines are engineered for precision and repetition, enabling manufacturers to produce large quantities of identical items with consistent quality and stable performance. The core function is to take pre-expanded EPS beads and fuse them together inside a custom-shaped mould, creating a solid, lightweight, and durable final product.

The technology behind these machines has evolved significantly. Modern EPS molding machines feature advanced PLC controls, energy-saving systems, and robust construction to handle the demanding cycles of industrial production. This allows for precise control over variables like steam pressure, temperature, and cycle time, which are all critical for achieving superior product quality and optimizing energy consumption. It’s a cornerstone technology for any serious EPS products manufacturer.

How Does the EPS Moulding Process Actually Work?

Understanding the working principle of an EPS shape molding machine is key to appreciating its value. The entire operation can be broken down into a few distinct, automated stages. It’s a fascinating process that turns small beads into robust products.

- Pre-Expansion: The journey begins not in the shape molding machine itself, but in an EPS pre-expander. Here, raw EPS beads, which contain a blowing agent (typically pentane), are heated with steam. This process is like making popcorn; the heat softens the polystyrene and vaporizes the pentane, causing them to expand up to 50 times their original size. This step determines the final density of the EPS product.

- Conditioning (Aging): After expansion, the hot, moist expanded beads are pneumatically conveyed to large, open-mesh silos to cool and mature. During this aging period (typically 6-12 hours), the pentane gas inside the beads condenses, creating a partial vacuum. Air slowly diffuses into the beads, stabilizing their internal pressure and making them ready for the final molding stage. This ensures the beads have the necessary elasticity for the final fusion.

- Molding: This is where the magic happens inside the shape moulding machine. The conditioned EPS beads are fed into a closed mould. The mould is then injected with steam a second time. This causes the pre-expanded beads to expand further and fuse together, perfectly taking the shape of the mould cavity. The application of steam is carefully controlled to ensure a complete and strong fusion without damaging the material.

- Cooling: Once fusion is complete, the mould must be cooled down rapidly. This is typically done by circulating water through channels within the mould or by using a vacuum system. The vacuum not only aids in cooling but also helps to remove residual steam and moisture, stabilizing the newly formed EPS product and reducing its internal pressure for easier ejection.

- Ejection: After the product is sufficiently cool and rigid, the mould opens, and an automated ejection system, often using compressed air or mechanical pins, pushes the finished EPS part out of the mould cavity, ready for use or post-processing. The entire cycle, from filling to ejection, can be as short as a minute, allowing manufacturers to produce thousands of parts per day.

Why is Expanded Polystyrene (EPS) the Material of Choice?

Expanded Polystyrene (EPS) has become a dominant material across many industries for a reason. Its unique combination of properties makes it incredibly versatile and cost-effective. The benefits of eps are numerous, which is why it’s so widely used.

First and foremost, EPS is incredibly lightweight. It’s composed of about 98% air, trapped within a closed-cellular structure. This extremely low weight has significant advantages. For protective packaging, it means lower shipping costs compared to other materials. The packaging material minimises the total weight of the shipment, which means that transport fuel consumption is improved and vehicle emissions are minimised. For construction, it makes handling large insulation panels easy and reduces the structural load on buildings.

The second key benefit is its excellent insulating and shock-absorbing capability. The trapped air within the EPS structure is a poor conductor of heat, giving it excellent thermal insulation properties. This is why it’s a popular choice for building insulation, keeping homes warm in winter and cool in summer, and for containers designed to keep food fresh throughout the distribution chain. Its ability to cushion and absorb impact makes it ideal for protecting sensitive electronics, appliances, and other fragile items during transit. It can effectively protect a wide range of goods.

Finally, EPS offers fantastic value. The raw material is relatively inexpensive, and the molding process is highly efficient, allowing for mass production at a low cost per unit. Furthermore, EPS is moisture-resistant, has high compression strength, and is 100% recyclable. The fact that the material is moisture resistant also means that it does not promote the growth of mold or bacteria, making it suitable for applications with the highest hygiene requirements, such as food trays or seed trays, without loss of strength. This combination of performance, durability, and cost-effectiveness makes EPS a superior choice for a wide range of applications.

What Are the Key Components of a High-Quality EPS Molding Machine?

When investing in an EPS molding machine, you’re not just buying a piece of equipment; you’re investing in your production line’s reliability and efficiency. As an experienced manufacturer, I can tell you that the quality is in the details. Here are the critical components that distinguish a superior machine from an average one.

- Machine Frame and Mould System: The foundation of the machine must be robust, typically built from high-strength, stress-relieved steel plates to withstand the constant pressure cycles without deforming. The mould itself, often made from high-grade aluminum alloy, should have a polished, Teflon-coated surface to ensure smooth ejection and long life.

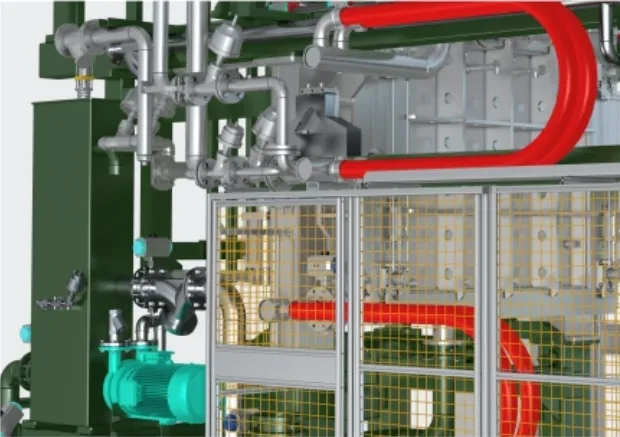

- Steam and Cooling System: This is the heart of the molding process. A high-quality machine will have a precise steam heating system with high-quality German or Japanese valves for accurate pressure and flow control. The cooling system, incorporating both water spray and a powerful vacuum system, is just as crucial for reducing cycle times and ensuring dimensional stability of the EPS products.

- Feeding System: An automated feeding system with level sensors ensures the mould is filled with the exact amount of EPS beads for every cycle. A reliable system prevents under-filling, which leads to weak products, and over-filling, which wastes material and can strain the machine.

- Control System (PLC): The brain of the operation. A user-friendly PLC (Programmable Logic Controller) with a touchscreen interface allows operators to easily set and monitor all parameters—steam time, cooling time, pressure, etc. This ensures consistent product quality, provides diagnostic information, and allows for storing recipes for different products.

- Safety Features: A reliable machine must prioritize safe operation. This includes safety doors with interlock systems, emergency stop buttons, pressure relief valves, and clear warning indicators. Compliance with international standards like CE marking is a non-negotiable indicator of a well-built, safe machine.

Can You Customize the Mould for Different EPS Products?

Absolutely. The versatility of an EPS shape molding machine lies in its ability to use interchangeable moulds. This is a fundamental feature that allows manufacturers to produce a vast array of various shapes and sizes using the same machine. The mould is the component that defines the final product, and its design is a critical aspect of the production setup.

The customization process begins with the product design. Whether you need a complex insert for automotive parts, a custom-fit packaging cushion for a new electronic device, or a decorative cornice for a building, a custom mould can be created. The mould is precision-engineered, typically using CNC machines, from a block of aluminum alloy. It includes the main cavity, core vents for steam to penetrate and air to escape, and channels for cooling water.

Changing a mould is a standard procedure. A well-designed EPS molding machine facilitates quick mould changes to minimize downtime between production runs of different items. This flexibility allows businesses to adapt to changing market demands, take on custom orders, and diversify their product offerings. From a simple tray to a complex bicycle helmet, the right mould is all it takes to transform your production capabilities and produce various shapes.

What Industries Rely on EPS Shape Moulding?

The applications for EPS foam products are incredibly diverse, touching almost every major industry. The unique properties of EPS make it an indispensable material for countless products, and the EPS foam shape molding machine is the key technology that makes it all possible.

Here’s a breakdown of key industries:

| Industry | Primary Use Cases | Key Benefits Leveraged |

|---|---|---|

| Packaging | Protective packaging for electronics, appliances, furniture, and medical equipment. Insulated boxes for shipping food and pharmaceuticals. | Shock absorption, lightweight, thermal conductivity, moisture resistance. |

| Construction | Insulated Concrete Forms (ICFs), geofoam for soil stabilization, architectural shapes, and panel insulation. | Excellent thermal insulation, lightweight, high compressive strength. |

| Automotive | Bumper cores, sun visors, interior padding, and components for child safety seats. Epp is also widely used. | Impact resistance, energy absorption, lightweight for fuel efficiency. |

| Horticulture | Seed trays and germination boxes. | Insulation to protect roots, moisture resistant, lightweight, durability. |

| Consumer Goods | Bicycle helmets, surfboards, bean bag filler, and insulated coolers. | Impact protection, buoyancy, insulation, lightweight. |

This widespread adoption is a testament to the versatility of EPS. A single high-quality EPS Shape Moulding Machine can empower a manufacturer to serve clients across multiple sectors, providing a stable and diversified business model. The ability to produce packaging materials one day and construction components the next is a powerful advantage.

How Can Automation in EPS Molding Boost Your Production Efficiency?

In today’s competitive market, efficiency is everything. Automation is no longer a luxury; it’s a necessity for any manufacturer looking to scale operations, reduce costs, and improve product quality. In EPS molding, integrating automation into your production line offers transformative benefits.

The core of this is the EPS foam shape molding machine itself, which automates the complex molding process. But true efficiency comes from automating the steps before and after the moulding. Imagine a seamless flow where manual intervention is minimized. This can involve an automatic feeding system linked directly from the conditioning silos to the moulding machines, eliminating the need for manual transport of pre-expanded beads.

After the part is ejected from the mould, downstream automation takes over. This can include:

- Robotic Arms: To pick the finished EPS parts from the machine and place them on a conveyor belt.

- Automated Conveyors: To transport parts to the next station, whether for quality control, drying, or packaging.

- Stacking and Packing Machines: To automatically stack, wrap, and prepare the EPS products for shipment, significantly reducing labor costs and manual handling errors.

By investing in an automated line, you can achieve higher throughput, ensure consistent cycle times, reduce labor dependency, and improve workplace safety. For a business owner like Mark, this translates directly into a healthier bottom line and a more reliable production output.

What Should You Look for When Choosing an EPS Shape Moulding Machine Supplier?

Choosing the right supplier for your EPS machinery is just as important as choosing the machine itself. A great machine from a poor partner can lead to frustration and downtime. As someone who has been in this business for decades, I understand the pain points our customers face. Here’s what you, as a discerning buyer, should prioritize.

First, look for expertise and a proven track record. Your supplier should be more than just a salesperson; they should be a technical partner. Do they manufacture the machines themselves in their own factory? Can they provide detailed technical specifications and offer customization options? A true specialist will understand the nuances of EPS production and can guide you to the best solution for your needs, whether you need one shape molding machine or a full turnkey plant.

Second, evaluate their commitment to after-sales service and support. This is where many relationships break down. Ask the tough questions:

- What does your installation and training process look like?

- How quickly can you provide technical support if we have an issue?

- Do you stock critical spare parts, and how fast can you ship them?

- Is your team fluent in English and accustomed to working with international clients?

Inefficient communication and slow support are major pain points that can halt your production. A reliable partner will offer comprehensive training, readily available spare parts, and responsive technical support to keep your operations running smoothly.

How Do You Ensure Safe Operation and Maintenance of an EPS Moulding Machine?

Operating heavy industrial machinery requires a steadfast commitment to safety and maintenance. An EPS shape molding machine involves high-pressure steam, automated moving parts, and electrical systems, making a proactive approach to safety essential. Durability means little if the machine isn’t operated correctly.

Proper training is the first line of defense. Your team should be thoroughly trained by the supplier on all aspects of the machine’s operation, including the control panel, emergency procedures, and daily safety checks. Operators must understand the function of every safety interlock and guard and never bypass them.

Regular maintenance is the second pillar of safe and reliable operation. This includes:

- Daily Checks: Inspecting for steam or water leaks, checking safety guards, and ensuring the work area is clean.

- Weekly Maintenance: Cleaning the mould surfaces, checking the lubrication of moving parts, and inspecting filters.

- Monthly/Annual Inspections: A more thorough check of the electrical systems, hydraulic/pneumatic components, and valve performance.

A good supplier will provide a detailed maintenance schedule. Following it diligently not only ensures safe operation but also extends the life of the machine, prevents unexpected breakdowns, and maintains consistent product quality.

What is the Future of EPS Molding and Recycling?

The future of the EPS industry is bright, driven by innovation in both materials and machinery. One of the most significant areas of focus is sustainability. While EPS is already 100% recyclable, the industry is continuously improving the efficiency of the recycling process.

This is where technologies like the EPS Recycling Machine come into play. These systems can take post-consumer or production scrap EPS, crush it, de-dust it, and prepare it to be re-integrated into new foam products. Other machines, like compactors and hot-melt densifiers, reduce the volume of EPS waste, making it economical to transport to recycling facilities. This focus on a circular economy is crucial for reducing waste and enhancing the environmental profile of EPS.

On the machine side, the trend is towards "Industry 4.0" integration. This means smarter moulding machines with enhanced sensors, data logging capabilities, and remote diagnostic tools. Imagine being able to monitor your production line’s efficiency, energy consumption, and maintenance needs from your office or even your phone. This connectivity will lead to more predictive maintenance, less downtime, and even higher levels of automation. The core technology of the EPS shape molding machine will continue to evolve, becoming faster, more energy-efficient, and more intelligent.

Key Takeaways

- Versatile Technology: The EPS Shape Molding Machine is a specialized piece of equipment that uses steam and a custom mould to create a vast array of lightweight, durable, and insulating products.

- Efficient Process: The moulding process is a multi-stage cycle of pre-expansion, conditioning, molding, cooling, and ejection that is highly automated for mass production.

- Superior Material: Expanded Polystyrene (EPS) is the material of choice due to its excellent insulation, shock absorption, low weight, and cost-effectiveness.

- Quality is Key: A high-quality machine is defined by its robust frame, precise control systems (PLC), and efficient steam and vacuum systems.

- Automation Drives Profit: Integrating automation before and after the molding stage significantly boosts efficiency, reduces labor costs, and improves consistency.

- Choose Your Partner Wisely: Your machine supplier is a long-term partner. Prioritize their technical expertise, after-sales support, communication, and availability of spare parts.

- Sustainability is the Future: The EPS industry is committed to recycling, with advanced machinery available to create a circular economy and reduce environmental impact.

Post time: 06-09-2025