Welcome. My name is Allen, and as a manufacturer in the EPS and EPP foam machinery industry for many years, I’ve had countless conversations with business owners like you. The heart of any successful Expanded Polystyrene (EPS) operation isn’t just the final product; it’s the efficiency and reliability of the machines that create it. The pre-expander machine is arguably the most critical component in this entire process. This article is your guide to understanding this pivotal piece of equipment, specifically focusing on the differences between batch and continuous models. We’ll explore how choosing the right expander can dramatically increase your output, lower your costs, and set your business up for long-term success. If you’re looking to optimize your EPS production, this is worth your time.

What Exactly is an EPS Pre-Expander and Why is it the Heart of Your Production Line?

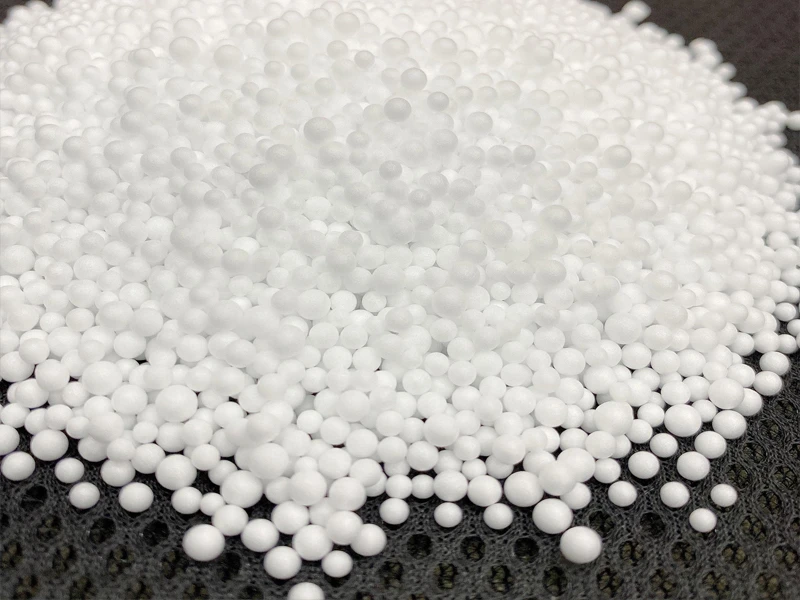

Before you can mold a block, shape a package, or cut an insulation board, you must first transform your raw material. This is the fundamental role of the EPS pre-expander. It takes tiny, solid polystyrene beads (your EPS raw material) and expands them using steam into the familiar, lightweight foam beads we all recognize. Think of it like making popcorn. You start with small, dense kernels and apply heat, causing them to ‘pop’ and expand to many times their original size. The pre-expander machine does this with incredible precision, controlling the final density and quality of the expanded polystyrene bead.

This initial pre-expansion stage is non-negotiable. The quality of the expanded bead produced here directly impacts every subsequent step in your production line. If the beads are inconsistently expanded, have non-uniform density, or contain too much moisture, you’ll face problems in the block molding or shape molding stages. This can lead to weak products, material waste, and production delays. That is why I always tell my clients, from seasoned operators like Mark Thompson in the USA to new ventures in Europe, that investing in a reliable pre expander is the most crucial decision you’ll make for your factory’s efficiency and profitability. It’s the true starting point of quality control.

Batch vs. Continuous Pre-Expander: Which is Right for Your Business?

One of the first questions you’ll face is whether to choose a batch or a continuous pre-expander. The choice depends heavily on your production volume, product requirements, and operational strategy. A batch pre-expander works, as the name implies, in distinct cycles. It completes one full cycle of feeding, heating, expansion, and discharging before starting the next. A continuous pre expander, on the other hand, performs all these steps simultaneously in a constant, uninterrupted flow.

To help you decide, let’s break down the core differences:

| Feature | Batch Pre-Expander | Continuous Pre-Expander |

|---|---|---|

| Production Model | Works in cycles (e.g., 2-4 minutes per batch) | Uninterrupted, continuous production |

| Best For | Lower volume needs, frequent density changes, specialty EPS | High-volume production, consistent density runs |

| Density Control | Very precise control for each individual batch | Excellent consistency for large runs, less flexible for rapid changes |

| Operational Labor | May require more manual intervention between batches | Highly automated, reduces labor costs |

| Footprint | Generally smaller | Can be larger due to the design |

| Initial Cost | Often lower | Typically a higher initial investment |

| Throughput | Lower overall output | Significantly higher production capacity |

For a company that needs to produce a wide variety of products with different densities throughout the day, a batch pre-expander machine might offer the required flexibility. However, for a business focused on high-volume production of standard items like insulation boards or large packaging blocks, the continuous eps pre-expander is the undisputed champion of efficiency. It’s designed to run for hours on end, churning out a consistent, high-quality bead that keeps the rest of your eps production line fed and productive.

How Does a Continuous EPS Pre-Expander Machine Work?

Demystifying the process helps you appreciate the engineering behind the machinery. A continuous EPS pre-expander machine operates through a seamless, automated sequence. First, the raw polystyrene beads are transported from a storage unit to the expander machine‘s loading hopper, often using a screw conveyor. An electronic weighing system ensures the correct amount of raw materials enters the system, which is the first step in achieving the target density.

From the hopper, a precise feeding mechanism, typically a rotary valve or screw, introduces the beads into the main expansion chamber. This chamber is where the magic happens. It’s a vertically oriented, sealed vessel where the beads are agitated and fluidized while controlled amounts of steam are injected. The heat from the steam softens the polystyrene and activates the pentane (a blowing agent) within each bead, causing it to expand. As the beads expand, their density decreases, and they become lighter. This causes them to rise to the top of the chamber.

Once the expanded beads reach the top, they are discharged into a fluid bed dryer. This critical step uses warm air to remove surface moisture and further cure the beads, preventing them from clumping together. Finally, the cool, dry, and stable eps beads are transported to a large storage silo, ready for the next stage of production. The entire process, from material feeding to silo loading, is a synchronized, continuous flow managed by the machine’s control system, requiring minimal manual intervention.

What Key Features Should You Look for in a High-Quality EPS Pre-Expander?

When you’re evaluating a pre-expander machine, especially from an overseas manufacturer, you need to look beyond the price tag. As an experienced machine manufacturer, I advise customers to focus on the features that guarantee reliability, efficiency, and longevity. Here’s a checklist of what truly matters:

- Construction Material: The expansion chamber and fluid bed dryer should be made of high-quality stainless steel. This resists corrosion from the steam and ensures the purity of your expanded polystyrene eps beads, preventing rust contamination.

- Precision Feeding System: Look for a machine with a reliable screw feeder and an accurate electronic weighing system. The ability to precisely control the amount of raw material entering the chamber is fundamental to consistent density.

- Advanced Steam Control: The machine should have high-quality pressure reducing valves and control valves from reputable international brands. Stable temperature and pressure are essential to expand the beads uniformly. Poor steam control is a common cause of inconsistent product quality.

- Efficient Fluid Bed Dryer: An integrated fluid bed dryer is not just an add-on; it’s essential. It ensures the beads are properly dried and cooled, which is critical for their stability during aging in the silo.

- Intelligent Sensor Technology: Modern pre-expanders use level sensors inside the expansion chamber to automatically control the material feed rate. This intelligent feedback loop ensures the main expansion process remains stable and produces a consistent output.

- Reputable Components: Pay attention to the brand of the electrical and pneumatic components. Using globally recognized brands means easier access to spare parts and greater overall reliability, addressing a common pain point for international buyers.

A machine with these features might have a higher upfront cost, but it will pay for itself through reduced downtime, lower waste, and consistent, high-quality eps production for years to come.

How Can a Continuous Pre-Expander Improve Production Efficiency and Lower Costs?

The primary advantage of a continuous pre-expander is its impact on your bottom line. The benefits are multifaceted. First and foremost is the sheer production capacity. A continuous machine can process significantly more material per hour than a batch unit, making it the ideal machine for factories with high demand. This increased throughput means you can fulfill larger orders faster, improving customer satisfaction and cash flow.

Secondly, automation is a major cost-saver. These machines are designed to automate the entire pre-expansion process. This drastically reduces the need for constant operator supervision, freeing up your workforce to focus on other value-added tasks and significantly cutting down on labor costs. The consistent, automated process also minimizes material waste. Unlike manual intervention, where human error can lead to spoiled batches, a continuous eps pre-expander produces a uniform product hour after hour. This means more of your expensive raw materials are converted into sellable product. Finally, modern expander machines are designed with energy consumption in mind, utilizing efficient steam systems and motors to keep your operational costs in check. The combination of higher output, lower labor, reduced waste, and better energy efficiency makes the continuous pre-expander a powerful tool for profitability.

What Role Does the PLC System Play in a Modern Expander Machine?

The Programmable Logic Controller (PLC) is the brain of a modern pre-expander machine. If you’re a business owner like Mark, who is decisive and focused on performance, understanding the PLC‘s role is key. It’s a robust industrial computer that manages and monitors every aspect of the machine’s operation. It’s the core of the machine’s automation capability. All the parameters—feeding speed, steam pressure, heating time, material level—are programmed into the PLC.

This provides several enormous advantages. The most important is repeatability. Once you dial in the perfect specification for a certain density, the PLC ensures that every single bead produced meets that exact standard. This eliminates the inconsistencies that can arise from manual adjustments. The control systems also feature a user-friendly touch screen interface, which simplifies operation. Your technicians can easily set recipes, monitor the machine’s status in real-time, and diagnose any potential issues through the on-screen alerts. This level of precise control not only guarantees product quality but also enhances safety by automating critical functions and providing immediate feedback. For any business serious about producing high-quality, consistent Styrofoam products, a reliable PLC system is not a luxury; it’s a necessity.

How Do You Ensure Uniform Density of Expanded Polystyrene (EPS) Beads?

Achieving a uniform density is the ultimate goal of the pre-expansion process. This consistency is vital for the structural integrity and performance of your final products, whether it’s protective packaging or thermal insulation boards. Several factors, all managed by a well-designed pre-expander, work together to achieve this.

The process starts with the electronic weighing system. By ensuring the exact same weight of raw material enters the pre expander machine for a given volume, you establish the foundation for your target density. The second key element is the steam control system. A high-quality pressure-reducing valve and precise control valve maintain a perfectly stable steam pressure and temperature inside the expansion chamber. Fluctuations in steam are a primary cause of density variations. Finally, the material level sensor inside the chamber provides real-time feedback to the PLC. It automatically adjusts the material feeding rate to maintain a constant level, ensuring that every bead spends the optimal amount of time in the heating and expansion zone. This closed-loop control system is what separates a basic expander machine from a truly professional one, capable of delivering the consistent quality that discerning customers demand.

What Should You Ask a Machine Manufacturer Before Purchasing an EPS Pre Expander Machine?

Choosing a partner for your machinery is as important as choosing the machine itself. As someone who has exported machines to North America, Europe, and Australia, I know that clear communication and trust are paramount. Here are the questions I encourage my potential customers to ask me, and that you should ask any manufacturer:

- What brand of PLC, electrical, and pneumatic components do you use? This tells you about the machine’s reliability and the ease of sourcing spare parts in your country.

- Can you provide a detailed technical specification sheet and explain each parameter? A good machine manufacturer will be transparent and able to explain how each dimension and specification relates to performance.

- What is your process for after-sales service and technical support? Ask about installation support, operator training, and how they handle troubleshooting. This is a major pain point for many buyers, and a clear answer is crucial.

- What is your typical lead time, and what guarantees do you provide for on-time delivery? Delays can be costly, so understanding the production and shipping timeline is essential.

- Can you provide references or case studies from customers in my region (e.g., the USA)? Speaking with an existing customer is one of the best ways to gauge a manufacturer’s performance and reliability.

- What safety features are included, and does the machine comply with international standards like CE marking? This is critical for protecting your workers and ensuring compliance with local regulations.

A professional eps manufacturer will welcome these questions and provide clear, confident answers. Vague responses or an unwillingness to discuss these points should be considered a major red flag.

Understanding the Technical Specification: What Do the Numbers Mean?

When you receive a quotation, the technical specification sheet can look intimidating. Let’s break down some of the key numbers for a continuous eps pre-expander machine:

- Chamber Dimension (Diameter x Height): This determines the machine’s physical size and its raw processing volume at any given moment.

- Production Capacity (kg/hr): This is one of the most important figures. It tells you the machine’s output for a specific density. For example, it might say "600 kg/hr @ 15g/L." Be aware that the capacity will decrease as the target density increases. Always ask for the capacity at the density you plan to produce most often.

- Expanded Density Range (g/L): This tells you the flexibility of the machine. A typical range might be 8-30 g/L. Ensure the machine can comfortably achieve the densities your products require.

- Steam Consumption (kg/ton): This is a critical operational cost factor. It tells you how many kilograms of steam are needed to produce one ton of expanded beads. A lower number means better energy consumption and a more cost-effective operation.

- Total Power (kW): This indicates the total electrical power consumption of all the motors on the machine, which helps you plan your factory’s power infrastructure.

Understanding these figures allows you to make a true apples-to-apples comparison between different models and manufacturers. It empowers you, the buyer, to move beyond the sales pitch and focus on the real-world performance and production needs of your factory. Choosing the right eps machine starts with understanding its capabilities on paper.

Beyond the Pre-Expander: Integrating it into a Full EPS Production Line

The EPS Pre-expander Machine is the first, vital step, but it’s part of a larger ecosystem. The expanded beads it produces are the lifeblood for the rest of your factory. From the aging silos, these beads are fed into other machines to create the final products. This is where a fully integrated system from a single, reliable supplier can prevent many of the headaches associated with mismatched equipment.

After pre-expansion, the beads typically go to an EPS Block Moulding Machine, where they are fused together into large blocks of Styrofoam. These blocks are then transferred to a complete EPS production line that cuts them into sheets of any desired thickness for insulation or construction. For more complex products, the beads are sent to an EPS Shape Moulding Machine to create custom packaging, helmets, or other intricate shapes. The process doesn’t end there; efficient operations also incorporate EPS recycling solutions to crush and reuse scrap material, minimizing waste and maximizing profit. As a Professional EPS Machine Manufacturer, we design our machines to work together seamlessly, creating a smooth, efficient, and highly productive workflow from raw bead to final product.

Key Takeaways to Remember

Making the right investment in an EPS pre-expander machine is foundational to your success. Here are the most important points to remember from our discussion:

- The Pre-Expander is Critical: The quality of your expanded beads determines the quality of your final products. Don’t compromise on this machine.

- Batch vs. Continuous: Choose a batch pre-expander for flexibility and lower volumes. Choose a continuous pre-expander for high-volume production, efficiency, and automation.

- Focus on Key Features: Prioritize stainless steel construction, precision feeding and steam controls, an integrated fluid bed dryer, and a reliable PLC system.

- Automation Drives Profit: A continuous machine’s ability to automate the process reduces labor costs, minimizes waste, and increases overall production capacity.

- Ask the Right Questions: Vet your manufacturer thoroughly. Inquire about component brands, after-sales support, delivery timelines, and safety certifications.

- Look at the Whole System: Consider how your pre expander will integrate with the rest of your production line to create a seamless and efficient operation.

Post time: 08-11-2025