As a manufacturer of EPS machinery, my name is Allen, and over the years, I’ve had countless conversations with business owners like Mark Thompson from the USA. They all face a similar, bulky problem: what to do with mountains of expanded polystyrene (EPS) waste. This lightweight, voluminous material clogs up warehouses, costs a fortune in disposal fees, and represents a significant environmental challenge. This article is your comprehensive guide to the ultimate solution: the EPS compactor. We will explore how this powerful machine can transform your waste management from a costly headache into a streamlined, profitable part of your operation, making your business more sustainable and efficient.

What is an EPS Compactor and Why is it Essential for Your Business?

An EPS compactor is a recycling machine designed specifically to tackle the challenge of EPS foam waste. Expanded Polystyrene, commonly known by the brand name Styrofoam, is famously composed of up to 98% air. This makes it an excellent material for packaging and insulation, but also incredibly difficult and expensive to handle as waste. The sheer volume of uncompacted EPS means it takes up a massive amount of space in dumpsters and warehouses, leading to high storage and transportation costs. Many businesses pay staggering fees for waste disposal, sending truck after truck of this lightweight material to the landfill.

This is where an EPS styrofoam polystyrene compactor becomes a game-changer. This piece of machinery takes bulky foam scrap and dramatically reduces its size. The primary function of the compactor is a machine that uses force to remove the air from the foam, transforming loose, cumbersome pieces into solid, dense blocks or logs. This process, known as foam compaction, can achieve incredible reduction ratios, often as high as 50:1. Imagine taking fifty bags of EPS waste and shrinking them down to the space of just one. For any company dealing with a steady stream of polystyrene foam, investing in a compactor is not just an operational upgrade; it’s a strategic financial decision that addresses logistical nightmares and environmental responsibilities head-on.

How Does a Styrofoam Compactor Machine Actually Work?

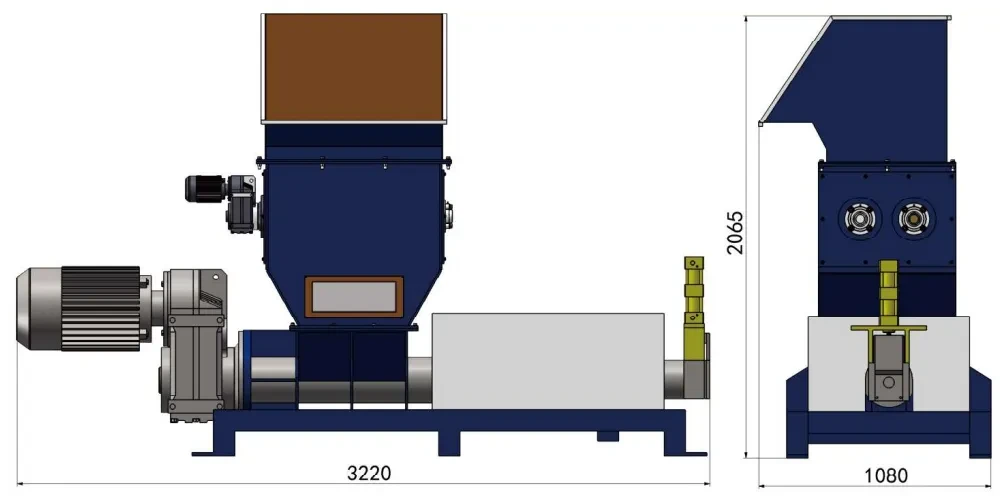

The process behind an EPS foam compactor is a marvel of engineering, designed for efficiency and simplicity. It all starts at the hopper, where the loose EPS foam waste is loaded, either manually or via a conveyor belt. Once inside, the material first encounters a shredder. This component features powerful blades that break the large, awkward pieces of Styrofoam into smaller, more manageable flakes. This pre-crushing step is crucial for ensuring a consistent flow of material into the core of the machine.

From the shredder, the EPS flakes fall into the compaction chamber, which houses the heart of the system: a large, powerful screw. This is why these machines are often called screw compactor units. The screw mechanism continuously turns, grabbing the shredded foam and forcing it down a channel. As the material moves along the screw, the channel gradually narrows, subjecting the EPS to immense pressure. This mechanical force is what performs the magic—it squeezes the air out of the foam cells, causing them to collapse and fuse together. The result is a continuous, hot, and highly dense log, known as a briquette, that is slowly extruded from the end of the machine. This entire process is a highly efficient method of reducing the volume of EPS without the use of chemical additives.

What are the Different Types of EPS Foam Compaction Machinery?

When looking for an EPS foam compactor for sale, you will encounter two primary technologies: cold compactors and hot melt densifiers. While both aim to reduce the size and volume of EPS waste, they achieve this through different methods, resulting in a different end product. Understanding this distinction is key to selecting the right recycling solution for your needs.

A cold screw compactor, often just called an EPS compactor, relies purely on physical force. The friction and intense pressure generated by the screw are enough to compress the foam into a dense briquette. This method is energy-efficient and produces no fumes, making it a popular choice for a wide range of facilities. The resulting compacted Styrofoam blocks have a high density and are easy to stack and transport.

A hot melt densifier, on the other hand, adds heat to the equation. As the screw pushes the EPS forward, heating elements melt the foam. The molten plastic is then extruded and cools into an even denser ingot, resembling a solid plastic block. This process can achieve higher compaction ratios, sometimes up to 90:1. The trade-off is higher energy consumption and the need for proper ventilation to handle the fumes produced during melting.

| Feature | Cold EPS Compactor | Hot Melt Densifier |

|---|---|---|

| Method | High-pressure screw compression | Heat and screw compression |

| Compaction Ratio | Up to 50:1 | Up to 90:1 |

| End Product | Dense briquette/log | Solid, melted ingot |

| Energy Use | Lower | Higher |

| Fumes | None | Yes (requires ventilation) |

| Best For | General foam recycling, high throughput | Maximum volume reduction, creating a high-value commodity |

We manufacture both types to suit different operational needs. Our standard EPS Compactor Machine is a robust cold-press system perfect for most applications, while our EPS Hot Melt Machine serves clients who need the absolute highest density for their recycling stream.

Can You Recycle All Types of Polystyrene Foam with a Compactor?

This is a frequent and important question. While the terms Styrofoam and polystyrene are often used interchangeably, there are different types of foam materials. An EPS compactor is specifically designed and optimized for Expanded Polystyrene (EPS), which is the most common type used in packaging for electronics, furniture, and food containers like fish boxes. The rigid, beaded structure of EPS is perfect for the shredding and screw compression process.

These machines can often handle other similar rigid foams as well. This includes:

- Expanded Polypropylene (EPP): A more flexible and durable foam used in automotive parts and high-end packaging.

- Expanded Polyethylene (EPE): A soft, semi-rigid closed-cell foam used for protective padding.

- Extruded Polystyrene (XPS): The rigid, often colored foam boards used for building insulation.

However, the performance and compaction ratio may vary depending on the specific material’s density and properties. It is always recommended to run a test with your specific foam types to ensure optimal results. These compactors are not suitable for soft, flexible polyurethane foams found in cushions or mattresses. Their primary purpose is to recycle the rigid polystyrene foam packaging that constitutes a major portion of industrial and commercial waste streams.

What are the Key Benefits of Compacting EPS Styrofoam?

Investing in a styrofoam compactor machine delivers a powerful return across multiple facets of your business. The benefits go far beyond simply tidying up your workspace. For business owners focused on the bottom line and operational efficiency, the advantages are clear, tangible, and swift.

Here are the primary benefits of compacting EPS:

- Massive Volume Reduction: This is the most immediate and impactful benefit. As mentioned, EPS foam is mostly air. By removing that air, a compactor drastically shrinks your waste footprint. A common industry metric is that a compactor reduces the volume of waste so effectively that what used to require 4 truckloads for disposal can now fit into a single one. This frees up invaluable floor space in your facility.

- Significant Cost Savings: The financial impact is twofold. First, you dramatically lower your waste disposal fees. Fewer dumpster pickups and lower landfill tonnage charges translate directly to monthly savings. Second, you reduce transport costs. Whether you are hauling waste yourself or paying a service, moving air is expensive. Shipping dense, compacted blocks is far more cost-effective.

- Creation of a Revenue Stream: This is where an EPS compactor transforms a liability into an asset. Compacted EPS is not trash; it is a valuable, sought-after commodity. The dense briquettes are purchased by recyclers and manufacturers who use them as raw materials for new products. Instead of paying to have your Styrofoam taken away, companies will pay you for it.

- Enhanced Environmental Responsibility: In today’s world, corporate sustainability is more important than ever. By diverting thousands of cubic meters of foam from the landfill, you are making a powerful statement about your company’s commitment to the environment. This can enhance your brand image and appeal to eco-conscious customers and partners. This is a truly sustainable waste management practice.

How Do You Choose the Right EPS Compactor for Sale?

Selecting the right EPS compactor requires a careful assessment of your specific needs. As a manufacturer, I advise my clients to look beyond the price tag and consider the factors that will ensure the machine is a reliable and efficient part of their workflow for years to come. A cheap, underpowered machine can quickly become a bottleneck.

First, consider capacity, which is typically measured in kilograms or pounds per hour. You need to estimate the volume of EPS waste your facility generates daily. Choose a machine with a capacity that can comfortably handle your peak waste production without running constantly. It’s better to have a slightly oversized machine than one that can’t keep up.

Next, examine the output density. The goal of foam recycling is to compress the material as much as possible to maximize shipping weight and value. A good compactor should produce a consistently dense and uniform briquette. Also, look at the features and build quality. Is the screw made from hardened, durable steel? Does the machine have automated features, like sensors in the hopper to start and stop the motor, preventing it from running empty? Is the electrical system compliant with your country’s standards? These details, which we build into all our machinery, are what separate a high-performance recycling machine from a basic one.

Which Industries Generate Significant Volumes of EPS Waste?

The problem of bulky EPS waste is widespread across many sectors. Any business that receives or ships large quantities of goods is likely a prime candidate for an EPS compactor. Over the years, I’ve supplied these machines to a diverse range of industries, all of whom were struggling with polystyrene foam management.

- Retail and Distribution Centers: Large retailers, especially those dealing in electronics and home appliances, are among the biggest generators of EPS packaging. Every TV, computer, and kitchen appliance is typically cushioned by custom-molded EPS foam.

- Manufacturing: Companies that produce goods use EPS to protect their products during shipping. Furniture manufacturers, for example, use large blocks and sheets of foam.

- Food Processing and Distribution: The seafood industry is a massive user of EPS. Insulated Styrofoam fish boxes are essential for transporting products like fresh salmon from places like Denmark and Norway to markets around the world. These boxes quickly pile up at processing plants and supermarkets.

- Pharmaceutical and Medical: Temperature-sensitive shipments of medicines and lab samples are often transported in EPS coolers, creating a steady stream of high-quality, clean recyclable waste.

For any of these businesses, a styrofoam compactor provides an on-site, practical, and profitable recycling solution, turning a constant stream of waste into a manageable and valuable resource.

What Happens to the Compacted EPS Briquettes After Processing?

This is the most exciting part of the recycling process because it demonstrates a true circular economy. The compacted EPS briquettes you produce are not the end of the line; they are the beginning of a new one. These dense blocks are a globally traded commodity. They are sold to a specialized recycler or processor, who will then take the material to the next stage.

At the recycling facility, the EPS logs are fed into a large grinder or granulator, which breaks them down into small, uniform beads or granule pellets. These pellets are the raw materials for a surprising variety of new products. This re-processed polystyrene is used to manufacture:

- Picture Frames and Architectural Moulding: Many ornate picture frames and crown moldings are made from recycled polystyrene.

- Hardwood Substitutes: The material can be used to create synthetic wood for park benches, decking, and fences.

- Coat Hangers and Office Supplies: Everyday plastic items are often made from recycled EPS.

- New Insulation Panels: The recyclable material can be used to create new rigid foam insulation boards.

- Lightweight Concrete: EPS granules can be mixed into cement to create a lightweight, insulating concrete used in construction.

By compacting your EPS, you are not just saving money; you are actively supplying the raw material for these industries, closing the loop and ensuring that this valuable plastic polymer is reused instead of being buried in a landfill.

How Do You Integrate an EPS Recycling Machine into Your Production Line?

Proper integration is key to maximizing the efficiency of your EPS recycling program. You don’t want your compactor to be an isolated island; it should be a seamless part of your facility’s waste handling workflow. The ideal setup often starts with a designated sorting area where EPS is separated from other waste materials like cardboard and plastic film.

From there, a conveyor system can be used to automatically feed the EPS scrap directly into the hopper of the compactor. This reduces labor costs and ensures a steady, continuous flow of material to the machine. For facilities that generate very large or intermittent volumes of EPS waste, a shredder and silo system can be installed upstream of the compactor. The foam is shredded and blown into a large storage silo. The compactor can then draw material from the silo as needed, allowing for a fully automated and continuous compaction operation.

We often work with clients to design a complete system. For instance, a facility might have a crusher and de-duster for cleaning dirty foam, which then feeds into a EPS Silo for storage before being processed by the compactor. Proper placement and workflow design turn your recycling machine from a standalone unit into a powerful component of your production line.

What is the ROI of an EPS Recycling Solution?

For any business owner, the final question always comes down to the return on investment (ROI). An EPS compactor is not an expense; it is a capital investment that pays for itself. The payback period is often surprisingly short, sometimes as little as one to two years, depending on the volume of EPS you process.

You can calculate your potential ROI with a simple formula:

Monthly Savings = (Old Monthly Disposal Costs) – (New, Lower Disposal Costs) + (Monthly Revenue from Selling Briquettes)

Payback Period in Months = (Total Cost of Compactor) / (Monthly Savings)

When you factor in the money saved on landfill and transportation costs and add the new revenue generated from selling the compacted EPS, the financial case becomes compelling. The machine works to save you money on waste and make you money on recycling simultaneously. It’s a clear win-win that improves your bottom line while also bolstering your company’s green credentials. It is one of the most direct and impactful investments you can make in efficient and sustainable operations.

Key Takeaways for EPS Compaction

Turning bulky Styrofoam waste into a valuable asset is not just possible; it’s a smart business strategy. A compactor is the key piece of machinery that makes it happen.

- Problem: EPS foam is 98% air, making it extremely costly to store and transport for disposal.

- Solution: An EPS compactor uses a powerful screw mechanism to compress the foam, reducing its volume by up to 50:1.

- Benefits are Financial and Environmental: You will drastically cut disposal and transport costs, create a new revenue stream by selling the compacted briquettes, and keep tons of foam out of landfills.

- Choose the Right Machine: Select a compactor based on your waste volume (capacity in kg per hour), desired output density, and robust, durable construction.

- A Valuable Commodity: Compacted EPS is not waste. It is a sought-after raw material used to manufacture a wide range of new consumer and construction products.

- Fast ROI: The combined savings and revenue often allow the machine to pay for itself in a surprisingly short period, making it one of the most effective investments in waste management.

Post time: 09-09-2025