Hello, my name is Allen. For over twenty years, I’ve been manufacturing EPS and EPP foam machinery right here in China. I’ve spent countless hours at exhibitions talking to business owners like Mark Thompson from the USA—sharp, decisive leaders who need reliable equipment to stay competitive. They all face a similar challenge: how to cut Thermocol (also known as EPS or polystyrene) with the speed, precision, and consistency that modern production demands. Manual methods are slow, messy, and simply can’t produce the complex shapes customers want.

This is where the CNC Thermocol cutting machine comes in. This guide is my direct-from-the-factory floor explanation of this incredible technology. We will explore how this machine is working, its various applications, and what you need to know to choose the right one. If you’re looking to upgrade your production, reduce waste, and unlock new design possibilities, this article will provide the essential insights you need.

What is a CNC Thermocol Cutting Machine and How is it Working?

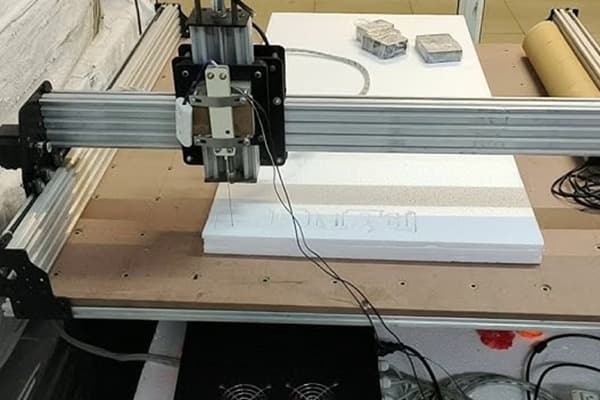

Let’s start with the basics. A CNC Thermocol cutting machine is a sophisticated piece of equipment that uses a heated wire to slice through Thermocol or EPS foam with incredible accuracy. The "CNC" part stands for Computer Numerical Control, which is the brain of the operation. Instead of a person guiding a cutting tool by hand, a computer precisely controls every movement. An operator creates a digital design on a computer, sends it to the machine, and the machine executes the cut flawlessly.

The working principle is both simple and brilliant. The machine doesn’t cut the Thermocol in the traditional sense, like a saw cuts wood. Instead, it uses a thin, taut nichrome wire that is heated to a specific temperature. This hot wire literally melts a very fine path through the foam as the machine guides it. Because the wire is so thin and the melting is localized, it leaves a smooth, sealed edge with almost no dust or debris. This process is clean, fast, and capable of producing intricate shapes that would be impossible to achieve by hand.

Why Use a CNC Machine to Cut Thermocol EPS?

For any business that works with EPS, the move from manual to CNC cutting is a transformative one. The benefits go far beyond just a cleaner cut. The primary advantage is the combination of precision and repeatability. A CNC machine can cut a design with an accuracy of a fraction of a millimeter. More importantly, it can produce that exact same part a thousand times without any deviation. This consistency is essential for industrial applications where every component must be identical.

The efficiency gains are also massive. A CNC cutting machine can work faster and for longer hours than any manual operator. It can optimize the cutting path to minimize waste, fitting as many parts as possible onto a single sheet of Thermocol. This not only saves on material costs but also speeds up production cycles dramatically. For companies in packaging, construction, or signage, this means faster turnaround times for customers and higher output. The versatility of a CNC machine allows a single piece of equipment to handle a huge range of jobs, from simple lettering to complex architectural moldings, making it an invaluable tool.

What are the Key Components of a CNC Thermocol Cutter?

When you look at a CNC Thermocol cutter, you’ll see several key parts working together. Understanding these components helps you appreciate how the machine achieves its precision and reliability. As a manufacturer, I can tell you that the quality of each part is critical to the machine’s overall performance.

- The Frame: This is the skeleton of the machine. It must be rigid and heavy to absorb vibrations and ensure that the cutting movements are perfectly stable. A flimsy frame will result in wavy, inaccurate cuts.

- The Control System: This is the brain. It’s a dedicated computer and electronic interface that reads the G-code from your design file and translates it into electrical signals that direct the motors. A user-friendly control system simplifies operation and reduces errors.

- Drive System (Motors and Guides): High-precision stepper or servo motors are used to move the cutting wire along the different axis points (X, Y, Z). These motors work with linear guides and ball screws to ensure smooth, precise motion without any backlash.

- The Hot Wire Assembly: This is the cutting tool. It consists of the nichrome wire, a tensioning system to keep the wire perfectly straight, and a power supply that provides the electricity to heat the wire to the correct temperature.

How Does the Hot Wire Cutting Process for Thermocol Work?

The magic of thermocol cutting lies in the physics of the hot wire. The wire itself, usually made of a nickel-chromium alloy (nichrome), has a high electrical resistance. When electricity is passed through it, it gets very hot. The key is to control this heat precisely. The goal is not to burn the Thermocol, but to melt it cleanly right at the point of contact. The temperature needs to be just right—hot enough to melt the EPS material effortlessly as the machine moves, but not so hot that it melts too wide of a path or causes the foam to char.

The speed at which the wire moves through the material is directly related to the wire temperature. A hotter wire allows for a faster cut, while a lower temperature will require a slower feed rate. Finding the perfect balance between these two parameters is essential for achieving a high-quality finish. A well-tuned machine will make a cut that is incredibly smooth, almost as if the piece was molded that way. This cutting-edge technology eliminates the need for sanding or other finishing steps, saving time and labor.

What Software is Necessary for CNC Thermocol Cutting?

You don’t need to be a computer programmer to operate a CNC thermocol cutting machine, but you do need to understand the two-step software workflow. This process takes your idea from a concept to a physical object.

- CAD (Computer-Aided Design): This is where you create your design. You can use a wide range of software programs, from simple 2D drawing programs to powerful 3D modeling software like AutoCAD, SolidWorks, or Rhinoceros. In this stage, you draw the exact shape and dimensions of the part you want to cut. The output of this stage is a digital file, like a DXF or an STL file.

- CAM (Computer-Aided Manufacturing): This software acts as the bridge between your design and the machine. The CAM program imports your CAD file and allows you to define the cutting strategy. You tell it the thickness of the material, the speed you want to cut at, and you generate the "toolpath"—the exact path the cutting tool (wire) will follow. The CAM software then exports a special file, usually in a language called G-code, which contains all the specific instructions the CNC machine needs to execute the cut.

What are the Main Industrial Applications for This Cutting Machine?

The versatility of the thermocol cnc cutting machine means it is widely used across many different industries. Its ability to quickly and affordably create custom shapes from a lightweight material makes it an invaluable tool.

Here are some of the primary fields where this machine is essential:

| Industry | Application Examples | Why it’s Suitable |

|---|---|---|

| Construction | Architectural moldings, insulation panel systems, concrete forms, decorative columns. | Ability to cut large, precise shapes for building components. |

| Packaging | Custom protective inserts for electronics, medical equipment, and fragile goods. | Quickly produces high-quality, perfectly-fitted cushioning for any product. |

| Signage & Displays | Large 3D logos, lettering for events, trade show booth elements, retail displays. | Cost-effective way to create eye-catching, large-scale visual elements. |

| Arts and Crafts | Movie props, theatrical sets, art installations, sculpture armatures, hobby models. | Offers incredible freedom for artistic expression, making complex designs easy to realize. |

This is just a snapshot. I have seen our machines used for everything from making giant chess sets to creating molds for fiberglass boat parts. The only real limit is your imagination.

Can You Cut Complex 3D Shapes with a CNC Thermocol Machine?

Absolutely. While basic machines are designed for 2D cutting (like cutting letters out of a sheet of Thermocol), more advanced machines offer the ability to create truly complex 3D shapes. This capability depends on the number of axes the machine can control.

A standard CNC thermocol cutting machine has at least two controllable axes (X and Y), which allows it to cut any 2D profile. However, more advanced machines use four axes. A 4-axis machine can move the two ends of the cutting wire independently of each other. This allows it to cut tapered shapes, like an airplane wing that is thicker at one end and thinner at the other.

For the most complex 3D work, a fifth rotary axis can be added. This is essentially a turntable that holds and rotates the Thermocol block while the hot wire cuts it. This combination of linear and rotational movement makes it possible to cut intricate shapes like columns with spiral flutes, spheres, and detailed sculptures. These advanced capabilities are what allow the machine to produce parts that were once only possible through painstaking hand-carving or expensive molding processes.

What Material Preparation is Required Before You Cut a Thermocol Sheet or Block?

The old saying "garbage in, garbage out" is very true for thermocol cutting. The final quality of your cut part is heavily dependent on the quality of the raw material you start with. For the best results, you need to use a high-quality block of Expanded Polystyrene (EPS). This means the foam beads should be well-fused together with a consistent density throughout the block. Low-quality Thermocol with large voids or poorly fused sections will result in a rough, uneven cut surface.

This is why the entire production chain is important. The process starts with a reliable block molding machine that can produce dense, stable blocks. For our customers who need full control over their material quality, we often recommend a system like our Mould Adjustable EPS Block Molding Machine, as it allows them to produce the perfect raw material for their cutting needs. Once you have a good block, the only other preparation is to ensure it is securely fastened to the machine’s cutting bed. Any movement or vibration during the cut will compromise the accuracy, so proper handling and clamping are essential.

How Do You Choose the Right CNC Thermocol Cutting Machine for Your Industry?

Choosing the right cutting machine is a critical decision. It’s an investment that should serve your business for years. As someone who speaks with buyers constantly, I advise them to focus on a few key areas beyond just the price tag.

First, consider the size. The machine’s work area must be large enough to handle the biggest project you plan to take on. It’s always better to have a slightly larger machine than one that is too small. Second, evaluate the machine’s construction. Look for a heavy, welded steel frame, high-quality motors, and reliable electronic components. A robust build is crucial for long-term industrial use.

Most importantly, consider the manufacturer. A good partner will provide more than just a machine; they will provide training, technical support, and a reliable supply of spare parts. This is a major pain point for many buyers, and it’s why a relationship with a dedicated manufacturer is so valuable. Whether you need a standalone CNC EPS Cutting Machine or a fully automated system like our Best Sale EPS Cutting Line, the level of support you receive is just as important as the hardware itself.

What are the Various Parameters to Control for a High-Quality Cut?

Achieving that perfect, glass-smooth finish on a cut piece of Thermocol comes down to fine-tuning a few key parameters on your cutting machine. While modern machines make this process easy, understanding what you are controlling is important.

The most critical parameter is the wire temperature. This needs to be adjusted based on the density of the EPS foam and the desired cutting speed. A higher density foam will require a slightly higher temperature or a slower speed to cut cleanly. The goal is a perfect melt without scorching the material.

The second key parameter is the cutting speed, or feed rate. This must be perfectly synchronized with the wire temperature. If you move the wire too fast for its temperature, it will drag and stretch, resulting in an inaccurate cut. If you move it too slowly, the wire will dwell in one spot for too long, melting an oversized kerf and potentially damaging the surface finish. Finding the sweet spot between these two variables is the secret to producing consistent, high-quality parts every time.

Post time: 09-29-2025