Hello, I’m Allen. For over twenty years, I’ve been manufacturing EPS and EPP foam machinery here in China. I’ve spoken with hundreds of business owners at exhibitions around the world, people just like Mark Thompson from the USA, who run successful companies but face one massive, lightweight problem: Styrofoam waste. It’s bulky, it’s everywhere, and it costs a fortune to get rid of. This article is your guide to the solution. We will dive deep into the world of the Styrofoam compactor, a powerful machine that can transform your waste disposal from a costly headache into a streamlined, efficient, and even profitable part of your operation. This is about more than just cleaning up; it’s about smart business and responsible manufacturing.

What is a Styrofoam Compactor and How Does it Revolutionize EPS Recycling?

A Styrofoam compactor is a specialized piece of equipment designed to solve the biggest problem with polystyrene foam: its volume. Expanded Polystyrene (EPS), commonly called Styrofoam, is about 98% air. This is what makes it such a great material for insulation and protective packaging, but it’s also what makes it a nightmare to recycle. A compactor tackles this problem head-on. It takes large, awkward pieces of waste foam and uses immense mechanical pressure to force the air out and compress the material into dense, solid blocks.

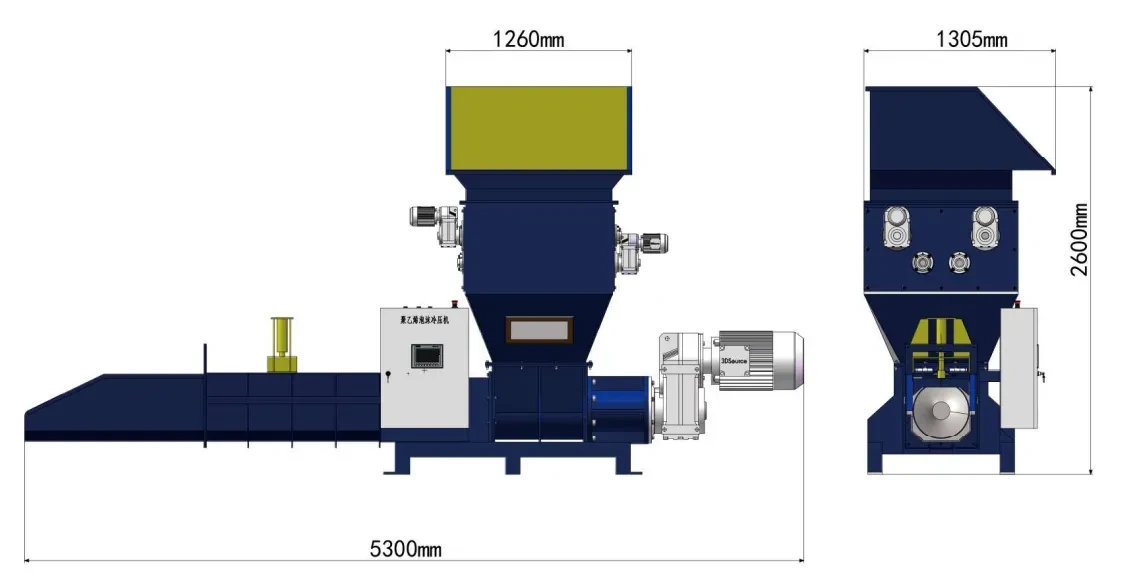

The most common type, a cold-press or screw compactor, works a bit like a giant meat grinder for foam. An operator feeds loose EPS waste into a hopper. Inside, a large screw auger grabs the foam, breaks it into smaller pieces, and pushes it forward with tremendous force into a chamber. This pressure collapses the foam’s cellular structure, squeezing out the air. The friction also generates a small amount of heat which helps the surface of the polystyrene melt slightly, acting as a binder. The result is a continuous, dense log or block of EPS that emerges from the machine. This process doesn’t change the chemical makeup of the plastic; it just changes its form, making it ready for the next stage of the recycling process.

This compaction process is the linchpin of modern EPS recycling. Without it, the logistics of collecting and transporting foam are economically impossible. By transforming a mountain of light, airy waste material into heavy, stackable blocks, the Styrofoam compactor makes it feasible to gather and ship the material to a recycler. It’s the key that unlocks the potential to recycle Styrofoam on an industrial scale, turning a landfill-bound problem into a valuable commodity.

Why is Compacting EPS Foam the Smartest Way to Recycle Polystyrene?

The simple answer is economics and logistics. Trying to recycle loose EPS foam is like trying to transport a truckload of feathers—you’re paying to ship air. Imagine your factory floor is cluttered with bulky EPS offcuts, used packaging, or rejected parts. You fill up a dumpster, and what’s inside? Mostly empty space. Your waste management bill reflects the volume, not the weight. This is a massive inefficiency that hits your bottom line directly.

A Styrofoam compactor flips this equation. By using compaction to reduce the volume of the foam, you can achieve reduction ratios of up to 50:1. This means the space that once held one pallet of loose foam can now hold the equivalent of 50 pallets of compacted foam. The impact is immediate:

- Drastically Lower Disposal Costs: Your dumpster pickups become far less frequent, saving you thousands of dollars per year.

- Valuable Floor Space Reclaimed: Instead of dedicating a significant area to bulky waste Styrofoam, you can store the dense, stackable blocks in a fraction of the space.

- Efficient Transportation: It becomes economically viable to ship the compacted blocks to a recycling center. A truck can be filled to its maximum weight capacity, making the journey worthwhile for a recycling company.

Beyond the direct economic benefits, compacting EPS is a powerful statement about your company’s commitment to sustainability. Instead of sending tons of non-biodegradable plastic to the landfill, where it will sit for centuries, you are actively preparing it for a new life. This is a crucial step in creating a circular economy for plastics and a powerful story to share with your customers and community. It is the most practical and environmentally friendly way to recycle this useful but problematic material.

What are the Different Types of Foam Compaction Machines?

When you begin looking for a foam compactor, you’ll find there are two primary technologies used to densify foam: cold compaction and thermal densification. Both aim to achieve the same goal—volume reduction—but they do it in different ways. Choosing the right one depends on your specific needs, the type of waste you have, and your operational goals.

| Feature | Cold Compactor (Screw Press) | Thermal Densifier (Hot Melt) |

|---|---|---|

| Method | Uses mechanical pressure from a screw to compress foam. | Uses heat to melt the foam into a dense, paste-like form which then cools into ingots. |

| Output Density | High (e.g., 200-400 kg/m³). | Very High (e.g., 600-800 kg/m³). |

| Energy Use | Lower. Relies on motor power for pressure. | Higher. Requires energy to heat the melting chamber. |

| Fumes/Odor | Minimal. Primarily a mechanical process. | Can produce fumes and odors as the plastic melts, requiring good ventilation. |

| Best For | General EPS, XPS, and EPE recycling. High-volume operations. | Businesses that need the absolute highest density for shipping, especially for long distances. |

| Complexity | Simpler, robust design. Easier to maintain. | More complex with heating elements and temperature controls. |

In my experience, the vast majority of businesses find that a cold compactor is the ideal solution. Screw compactors are incredibly reliable, energy-efficient, and can handle a wide variety of polystyrene foam products, from simple packaging to more challenging materials like wet EPS fish boxes. They are the workhorses of the foam recycling industry. Thermal densifiers, or what we call an EPS Hot Melt Machine, have their place for niche applications, but for most manufacturers and recyclers, the simplicity and efficiency of a cold press compactor make it the superior choice.

How Do Screw Compactors Work on Different Types of Foam Waste like Fish Boxes?

One of the great strengths of screw compactors is their versatility. While they are most commonly associated with standard white EPS foam from packaging and insulation, they can effectively handle various forms of expanded foam. This includes XPS (Extruded Polystyrene), often seen as colored insulation boards, and EPE (Expanded Polyethylene), a more flexible foam. The powerful screw mechanism is capable of breaking down and compacting these different types of foam.

A particularly challenging but important application is the recycling of EPS fish boxes. The seafood industry is a massive user of polystyrene for its excellent insulating properties. However, these boxes used for shipping are often wet and may have residual organic matter. A robust screw compactor is perfectly suited for this task. High-quality screw compactors, like the RUNI screw compactor models, are often built with stainless steel parts in key areas to resist corrosion from water and salt. The machine’s powerful screw can press the water out of the foam during the compaction process, effectively de-watering the waste EPS as it’s compacted.

This capability is a game-changer for fishing ports, seafood processors, and supermarkets. What was once a smelly, difficult-to-handle waste stream that was almost always sent to a landfill can be turned into a valuable resource. By compacting EPS fish boxes, they can be stored cleanly and shipped efficiently for recycling. The ability to handle this specific, challenging type of waste showcases the true power and utility of modern foam recycling technology.

Can a Styrofoam Compactor Really Make You Money?

Yes, absolutely. Investing in a Styrofoam compactor provides a clear and often rapid return on investment through two primary avenues: cost savings and revenue generation. These are the environmental and economic benefits that make the decision so compelling for business owners like Mark.

First, let’s talk about savings. Calculate how much you currently spend on waste disposal for your Styrofoam waste. This includes dumpster rental fees, hauling charges, and landfill tipping fees. For many businesses that generate even a moderate amount of foam scrap, this can amount to tens of thousands of dollars per year. A compactor can reduce your number of waste pickups by 90% or more. The machine often pays for itself within one to two years on these savings alone. You are also saving valuable employee time that was previously spent breaking down boxes, bagging loose foam, and managing a messy waste area.

Second, there is direct revenue. The compacted EPS blocks are not trash; they are a valuable commodity. There is a global market for recycled polystyrene. Recycling companies will purchase these dense blocks from you because they are an ideal feedstock for their operations. The price fluctuates with the market, but it is a consistent revenue stream. You transform an expense on your profit and loss statement into an asset. Instead of paying someone to haul away your foam, someone pays you for it. It’s one of the clearest win-win scenarios in modern waste management.

What Should You Look for in a High-Quality EPS Recycling Machine?

When you’re ready to purchase a compactor, you’re making a long-term investment in your facility’s infrastructure. It’s crucial to choose a machine that is reliable, safe, and efficient. As a manufacturer, I know the difference between a machine built to last and one that will cause problems.

Here are the key features to look for:

- Robust Construction: The machine should be built with a heavy-duty steel frame. The screw and chamber, the parts that do all the work, should be made from high-strength, wear-resistant steel to handle the immense pressure of compaction.

- Powerful and Efficient Motor: The drive system is the heart of the compactor. Look for a high-quality motor and gearbox from a reputable brand that provides high torque without consuming excessive energy.

- Intelligent Density Control: Advanced machines have sensors and automatic hydraulic jaws that control the back-pressure, allowing you to produce consistently dense blocks. This is critical for meeting the quality standards of recyclers.

- Safety First: The machine must have clear safety features, including an emergency stop button, safety interlocks on all access panels, and a hopper design that prevents accidental contact with the screw.

- Ease of Use and Maintenance: The control panel should be simple and intuitive. Components that require routine maintenance, like bearings, should be easily accessible.

Don’t just look at the price tag. Ask about the warranty, the availability of spare parts, and the level of technical support the supplier offers. A reliable partner who can provide support after the sale is just as important as the machine itself. An EPS Compactor Machine is a critical piece of operational equipment; choosing a high-quality unit from a reputable source is essential for long-term success.

How Do You Prepare Styrofoam for Recycling in a Compactor?

The principle of "garbage in, garbage out" applies perfectly to Styrofoam recycling. The quality of your output blocks is directly determined by the quality of the material you feed into the machine. To get the best price for your compacted EPS and to ensure the smooth operation of your compactor, you must feed it clean Styrofoam.

Before putting Styrofoam into the compactor’s hopper, it’s essential to remove any contaminants. This includes:

- Tape and Labels: Plastic tape and paper labels should be peeled off.

- Food Residue: For post-consumer packaging or fish boxes, the foam should be reasonably clean. A quick rinse can make a big difference.

- Other Materials: Ensure no wood, metal, paper, or other types of plastic are mixed in with the foam.

While some powerful screw compactors can handle a small amount of contamination, it’s always best practice to keep your waste foam stream as pure as possible. A simple sorting station next to the compactor can make this process efficient. By educating your staff on the importance of feeding only clean Styrofoam into the machine, you protect your investment, maximize the value of your recycled material, and contribute to a higher-quality recycling process downstream. A pile of clean, sorted foam is the first step to successful recycling of Styrofoam.

What Happens to the Compacted EPS Blocks After They Leave Your Factory?

The journey for your EPS foam doesn’t end when it leaves your facility as a dense block. This is really just the beginning of its second life. Those compacted EPS blocks are a raw material, and here’s what happens next:

- Transportation: The blocks are stacked on pallets and shipped to a specialized plastic recycling facility. Thanks to the compaction, this is now a cost-effective trip.

- Shredding and Cleaning: At the recycling center, the blocks are shredded or granulated into small, uniform beads or flakes. This material is then thoroughly washed and dried to remove any remaining dirt or contaminants.

- Melting and Extrusion: The clean polystyrene flakes are fed into an extruder. This machine melts the plastic and pushes it through a die to form long strands, similar to spaghetti.

- Pelletizing: These strands are immediately cooled in water and chopped into small pellets. These pellets are the final recycled product. They are uniform, easy to handle, and ready to be used as a raw material.

- Manufacturing New Products: These recycled polystyrene pellets are sold to manufacturers who use them to make a huge variety of new products. This includes items like picture frames, architectural moldings, park benches, coat hangers, and even new insulation and some types of construction materials. The foam you rescued from the landfill is now back in the consumer market, completing the circle.

Is it Truly Possible to Recycle Styrofoam Packaging?

Yes, it is 100% possible to recycle Styrofoam packaging. There is a persistent myth that Styrofoam is not recyclable. The material itself, the polystyrene plastic (marked with the number 6), is a thermoplastic, which means it can be melted and reformed again and again. The challenge has never been the material’s recyclability; it has always been the economics of collecting and transporting the bulky, lightweight foam.

This is precisely the problem that the Styrofoam compactor solves. It bridges the economic gap that made EPS collection so difficult to recycle in the past. By removing the air and creating a dense, valuable commodity, the compactor makes the entire recycling program viable. While you may not be able to put it in your home recycling bin because most curbside recycling programs aren’t equipped for it, it is absolutely recyclable through commercial and industrial channels.

Businesses that adopt compacting and recycling practices are the key to unlocking the potential of Styrofoam recycling. They act as crucial collection and pre-processing hubs. When a company invests in a foam compactor, they are not just managing their own waste; they are creating a node in the larger recycling network, proving every day that Styrofoam is recyclable and making the process a reality.

Where Can You Find a Reliable Styrofoam Compactor Supplier?

Choosing the right supplier for your Styrofoam compactor is as important as choosing the right machine. You need a partner who understands the technology, your industry, and is committed to your success. Look for a true manufacturer, not just a distributor. A manufacturer has direct control over the quality of the machine, from the steel they use to the components they source.

When evaluating suppliers, ask critical questions that address the common pain points I hear from buyers:

- "What is your process for ensuring on-time delivery and installation?"

- "What kind of training and technical support do you provide after the sale?"

- "How quickly can I get spare parts if I need them?"

- "Can you share case studies or connect me with existing customers in my region?"

A reliable supplier will have clear, confident answers. They will be transparent about their machine’s capabilities and work with you to select the right model for your specific volume of waste foam, whether it’s a smaller SK200 or a high-capacity machine designed to handle many tons per year. As a Professional EPS Machine Manufacturer, we believe our job isn’t done when the machine leaves our factory. We are invested in making sure it becomes a productive and profitable part of your operation for years to come.

Key Takeaways for Your Foam Recycling Strategy

Making the switch to compacting your Styrofoam waste is a smart business decision with far-reaching benefits. It streamlines your operations, improves your bottom line, and demonstrates a real commitment to the environment.

- Compaction is the Key: A Styrofoam compactor solves the biggest barrier to recycling—the foam’s high volume—by compressing it into dense, valuable blocks.

- Save Costs, Generate Revenue: Drastically reduce or eliminate waste disposal fees and sell the compacted EPS blocks as a commodity to recyclers.

- Choose the Right Technology: For most applications, a cold-press screw compactor offers the best balance of efficiency, reliability, and ease of maintenance.

- Quality In, Quality Out: Always feed your compactor clean Styrofoam free of tape, food, and other contaminants to maximize the value of your output.

- Styrofoam is Recyclable: Your business can be a vital part of the solution by using a compactor to make EPS recycling economically viable.

- Partner with an Expert: Select a reputable manufacturer who can provide a high-quality machine and the long-term support you need to succeed.

Post time: 09-23-2025