Imagine slicing through a massive block of white material as easily as a hot knife slides through butter. There is no dust, no noise, and the edge is perfectly sealed and smooth. This is not magic; it is the efficiency of a hot wire foam cutter. Whether you are a hobbyist building a model plane in your garage or a factory owner producing tons of insulation, understanding the physics and mechanics of this tool is essential. The process relies on a simple principle: using a heated wire to vaporize foam just ahead of contact, creating a precise cut without physical force.

In the world of EPS (Expanded Polystyrene) and EPP (Expanded Polypropylene) manufacturing, the hot wire is the industry standard. It transforms bulky raw blocks into intricate shapes, packaging, and construction panels. This guide will walk you through everything you need to know about the wire, the power supply, and the techniques required to master foam cutting. We will explore why nichrome wire is the king of cutters, how to manage heat, and how to choose the right cutting tool for your specific needs.

What Exactly is a Hot Wire Foam Cutter and How Does It Work?

At its core, a hot wire foam cutter is a remarkably simple device. It consists of a thin, taut metal wire stretched between two points, usually on a frame or a bow. When an electrical current passes through this wire, the resistance of the metal creates heat. This is the same principle used in a toaster or a space heater. However, instead of toasting bread, we use this controlled heat to melt through foam.

When you use a hot wire to cut foam, the wire itself typically does not touch the foam. The radiant heat vaporizes the material just fractions of a millimeter before the wire makes contact. This is why hot wire foam cutting leaves such a smooth surface. Unlike a saw, which tears the material and creates a "jag" or rough edge, the heat seals the cells of the foam as it passes. This prevents the mess of static-charged beads flying everywhere, which is a common headache with mechanical cutting.

The mechanism works best on thermoplastics like EPS and EPP that have a low melting point. The temperature of the wire must be carefully balanced. If the wire is too cool, it will drag and snap. If it is too hot, it will melt a wide cavern around the cut, ruining the precision. This balance is controlled by the voltage and amperage delivered by the power supply.

Why is Nichrome Wire the Gold Standard for Cutting Foam?

If you ask any professional or serious hobbyist what type of wire they use, the answer is almost always nichrome wire. Nichrome is an alloy made of nickel and chromium. It is the ideal material for a foam cutter for two main reasons: high electrical resistance and high melting point. High resistance means it gets hot very quickly when electricity flows through it.

Unlike copper wire, which conducts electricity too well and would simply short out your battery or transformer without generating enough heat, nichrome wire resists the flow, converting that energy into the heat needed to cut. Furthermore, nichrome wire does not oxidize or become brittle as quickly as other metals when heated repeatedly. It maintains its strength even when glowing red hot (though for foam, you rarely need it that hot).

You can find nichrome wire in various gauges. A thinner gauge (higher number) heats up faster and creates a finer kerf (the width of the cut), which is perfect for detailed RC models or architectural models. A thicker wire is more durable and better suited for large industrial machines that slice through massive blocks of insulation. You can often find this wire on eBay or even at a local vape shop, as it is used for vape coils.

Can You Use Steel or Stainless Steel Wire as an Alternative?

Many DIY enthusiasts try to save money by using steel wire, stainless steel welding wire, or even piano wire. While it is possible to cut foam with these materials, they come with significant drawbacks. Steel has a lower resistance than nichrome, meaning you need more amperage to get it hot enough.

The biggest issue with used steel or stainless steel wire is thermal expansion. All metal expands when heated, but steel tends to expand significantly. This causes the wire to go slack in the bow or frame as soon as it heats up. A loose wire leads to wavy, inaccurate cuts. To use steel effectively, you need a very strong spring tensioner system to take up the slack as the wire lengthens.

Additionally, steel wire becomes brittle after repeated heating and cooling cycles, leading to frequent snaps. Some people try using fishing trace wire or braid, but these often have coatings that burn off and create toxic fumes. While a guitar string (specifically the plain steel ones) can work in a pinch for a small hobby project, for reliable, consistent foam cutting, nichrome wire is worth the small investment.

How to Choose the Right Gauge Wire for Your Cutter

Selecting the correct gauge wire depends on what you are building. Wire diameters are measured in AWG (American Wire Gauge). The higher the number, the thinner the wire. For most handheld foam cutters used to make RC plane parts or small models, a 26 to 28 gauge nichrome wire is excellent. It heats up with very little power and creates intricate cuts.

For a larger, table-based cutter or a large bow cutter designed to slice 4-foot sheets of foam for insulation, you need something stronger. A 20 to 22 gauge wire is standard here. It is thicker, so it can withstand the tension required to keep a long span straight without breaking.

However, remember that a thicker wire requires more power. You will need a power supply capable of delivering higher amperage to get a thick wire to the cutting temperature. If you try to heat a thick welding wire with a small battery charger, you will likely overload the charger before the wire gets warm. You must calculate the resistance of your wire length to match it with your power source.

The Critical Role of the Power Supply and Transformer

The power supply is the engine of your hot wire foam cutter. You cannot simply plug a cutting wire into the wall outlet—that would be dangerous and would instantly melt the wire. You need a transformer to step down the voltage to a safe and usable level.

For many DIY setups, a 12v car battery or a LiPo battery is a convenient power source. They provide a steady current capable of heating thinner wires. However, a battery runs out. For continuous cutting, a variable DC power supply is ideal. This allows you to adjust the voltage and limit the current.

Why is variability important? Because the length of your wire changes the resistance. A short wire needs less voltage to get hot than a long wire. If you switch from a 12-inch bow to a 24-inch bow, you need to turn up the power. A dimmer switch (like the one used for house lights) connected to a transformer is a classic DIY solution to regulate the amount of heat. By turning the dimmer knob, you control the energy going into the transformer, which in turn controls the heat of the wire.

DIY vs. Professional: Building or Buying Your Foam Cutters?

Should you build a DIY cutter or buy a manufactured one? For simple hobby tasks, building a bow cutter from PVC pipe or wood is a fun project. You can use a battery holder for power and a simple switch. There are countless tutorials online for making a hot wire cutter using parts from a hardware store.

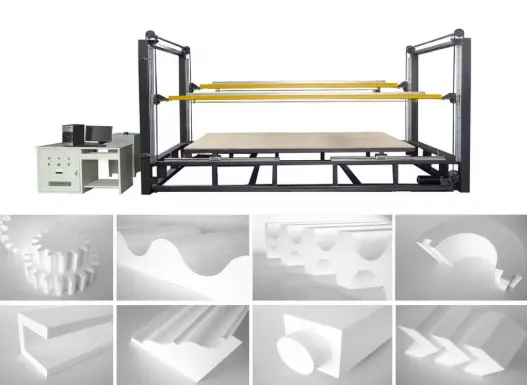

However, if you are running a business or need cutting tools for precise manufacturing, professional equipment is superior. Industrial foam cutters feature rigid frames, precise tensioning mechanisms, and sophisticated electronic controllers that maintain constant temperature even as the wire moves through the foam. This ensures that the cut is uniform from start to finish.

Professional machines, like our CNC EPS Cutting Machine, take this a step further. They use computer control to move the wire through complex 2D and 3D paths. These machines use heavy-duty nichrome wire or specialized alloys and high-output power supplies to run multiple wires simultaneously, dramatically increasing production speed for packaging and insulation products.

Mastering the Art of Foam Cutting: Speed, Heat, and Tension

Successfully cutting the foam is a skill that balances three variables: heat, speed, and tension.

- Heat: The wire should be hot enough to vaporize the foam just before contact, but not so hot that it glows bright red (unless cutting very rapidly). If you see excessive smoke, your wire is likely too hot.

- Speed: You must move the cutter at a steady pace. If you move too fast, the wire will drag, bend backward (creating a "U" shape), and ruin the accuracy. This is often called "drag." If you move too slow, the radiant heat will melt too much material, creating a wide, uneven cut.

- Tension: As mentioned, the wire will expand with heat. A spring tensioner on your bow or machine is vital to keep the wire straight.

The goal is to let the heat do the work. Do not force the wire through the foam. Apply gentle pressure and let the wire glide. If you feel resistance, slow down or increase the heat slightly.

Safety First: Handling Fumes and Electricity

Hot wire foam cutting is generally safe, but there are hazards. The most obvious is the heat. The wire can reach temperatures of over 300°C (572°F) instantly. Severe burns happen in a split second. Always be aware of where the wire is, even if it doesn’t look hot. The wire can stay hot for a few seconds after the power is cut.

The second hazard is fumes. Melting polystyrene releases chemicals. While EPS and EPP are generally considered less toxic than burning PVC or polyurethane, the fumes can still be irritating to the eyes and lungs. Always work in a well-ventilated area. Use a fan to vent the smoke away from your face, or wear a respirator rated for organic vapors.

Finally, respect the electricity. Even though you are likely working with low voltage (like 12V or 24V), the amperage can be high. Ensure all connections are insulated and that your power supply has a fuse or circuit breaker. Never leave a hot wire unattended.

Applications: From RC Wings to Industrial Insulation

The versatility of the hot wire foam cutter is unmatched. In the hobby world, enthusiasts use them to cut wing cores for RC airplanes. They use templates on either side of a foam block and guide the hot wire along the templates to create aerodynamic shapes.

In the industrial sector, hot wire machines are the backbone of EPS production. They are used to slice massive main blocks of EPS into sheets for building insulation. They cut intricate shapes for protective packaging that fits perfectly around TVs and appliances. They create decorative architectural moldings that look like stone but are lightweight foam.

For those interested in recycling, machines like the EPS Recycling Machine often work in tandem with cutting lines, processing the off-cuts and scraps generated during the hot wire process. This ensures that waste is minimized and materials are reused.

Troubleshooting Common Issues with Your Wire and Power Setup

Even the best setup can have issues. Here are a few common problems and solutions:

- The wire keeps breaking: You might be using a wire that is too thin for the tension, or you are forcing the cut too hard. Try a thicker gauge or increase the heat so you don’t have to push as hard. Also, check for sharp edges on your bow attachment points that might be cutting the wire.

- The wire heats up unevenly: This can happen if the connection points are dirty. Ensure the wire is securely clamped to the cable or terminals. A loose connection creates resistance and heat in the wrong place.

- The cut is wavy: Your tensioner is likely insufficient. As the wire heats and expands, it gets loose. Add a stronger spring.

- The transformer gets hot but the wire stays cold: You may have a short circuit, or your wire is too thick (resistance too low) for the transformer. The power supply is dumping all its energy but can’t overcome the load. You need a power supply with higher amp output.

Summary

The hot wire foam cutter is an indispensable tool for anyone working with foam. By understanding the properties of nichrome wire, the importance of a regulated power supply, and the balance of heat and speed, you can achieve professional results.

- Nichrome wire is the best material due to its high resistance and durability.

- A variable power supply or a dimmer setup gives you the control needed for different wire lengths and foam densities.

- Always use a tensioner to account for wire expansion.

- Ventilation is crucial to avoid inhaling fumes.

- Whether for a DIY hobby project or an industrial EPS Block Moulding Machine line, the principles of hot wire cutting remain the same.

Mastering this tool opens up a world of possibilities, from creating lightweight RC planes to building energy-efficient homes with EPS insulation.

Post time: 01-14-2026