Hello, my name is Allen. For years, I’ve managed the production lines at our factory, specializing in EPS and EPP foam machinery. At international exhibitions, I meet countless business owners like Mark Thompson from the USA. They are sharp, decisive leaders who need reliable, efficient equipment to stay competitive. They often ask, "What should I really be looking for in a thermocol cutting machine?" They’re tired of vague answers and inconsistent performance. This guide is my answer. It’s a look from inside the manufacturing world, designed to give you the clarity you need to select the right machine that will cut your thermocol blocks perfectly, enhance your production, and boost your bottom line.

What Exactly is a Thermocol Cutting Machine and Why is it Essential?

First, let’s clear up the terminology. "Thermocol" is a brand name that has become synonymous with Expanded Polystyrene (EPS), a lightweight, rigid foam used everywhere. So, a thermocol cutting machine is simply an industrial machine designed to slice large blocks of EPS foam into usable sheets, custom shapes, or detailed designs. This piece of machinery is the heart of many businesses in packaging, construction (for insulation panels), signage, and decorative arts. Without an effective cutting machine, a large thermocol block is just a bulky object with limited value.

The essential role of this machine is transformation. It takes a raw, oversized block and turns it into a finished product ready for market. Think about the custom foam inserts that protect a new television, the intricate architectural moldings on a building, or the lightweight letters for a large sign. All these products are born from a thermocol cutting machine. Investing in the right equipment is not just an operational decision; it’s a strategic one that directly impacts your product quality, production speed, and overall profitability. A good machine reduces waste, improves accuracy, and allows you to take on more complex jobs, opening up new revenue streams.

How Does a Hot Wire EPS Foam Cutting Machine Actually Work?

The magic behind the most common type of foam cutting machine is surprisingly simple yet incredibly effective: heating. A hot wire EPS foam cutting machine uses one or more high-resistance wires, typically made of a nickel-chromium alloy. When an electric current is passed through these wires, they heat up instantly, much like the element in a toaster. The machine frame holds these wires under tension, and a control system moves either the wires or the EPS foam block with precise movements. As the hot wire makes contact with the thermocol, it doesn’t mechanically cut it; it melts a very thin path through the material.

This melting process is what makes the hot wire method so ideal for EPS foam. It results in a perfectly smooth, sealed edge with virtually no dust or debris, which is a significant advantage over mechanical cutting methods that can create a mess. The speed and temperature of the wire are critical variables. Too hot or too slow, and the cut will be too wide. Too cool or too fast, and the wire might drag or break. Modern automatic machines use sophisticated control systems to maintain the perfect wire temperature and cutting speed, ensuring a consistent and accurate cut every single time. It’s a clean, efficient, and precise way to process EPS.

What are the Main Types of Thermocol Cutting Machines on the Market?

When you start exploring the market, you’ll find that thermocol cutting machine models fall into a few main categories. Choosing the right type depends entirely on your production volume, the complexity of the cuts you need, and your budget. As a supplier, I always advise clients to think about their future needs, not just their current ones.

Here’s a simple breakdown of the most common types of this machine:

| Machine Category | Description | Best For | Key Trade-off |

|---|---|---|---|

| Manual Machine | The operator manually pushes the EPS block through a stationary hot wire. | Small workshops, hobbyists, or very low-volume production. | Low cost, but inconsistent results and slow. |

| Automatic Machine | Uses motors to feed the block or move the wire array automatically. Set up for repetitive cuts. | High-volume production of standard sheets and simple rectangular blocks. | High speed and efficiency for one task, but limited flexibility. |

| CNC Machine | Computer Numerical Control (CNC) moves the hot wires along multiple axes based on a digital design file. | Custom shapes, complex profiles, architectural designs, and high-precision parts. | Highest versatility and precision, but higher initial investment. |

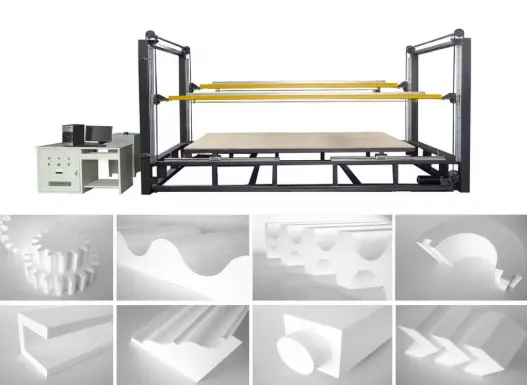

Most serious industrial operations will choose between an automatic or a CNC machine. An automatic cutting machine is a workhorse, perfect for businesses that need to produce thousands of standard EPS insulation sheets per day. A CNC foam cutting machine, on the other hand, is for the creator. It’s the machine you need if your product line involves custom packaging, architectural moldings, or any design that isn’t a simple straight line. Many modern machines combine both functions, offering a vertical and horizontal set of wires for both block squaring and sheet cutting in one automated process.

Why Should You Choose a CNC Thermocol Cutting Machine for High Precision?

When accuracy and complexity are your top priorities, a CNC thermocol cutting machine is the only real option. The "Computer Numerical Control" element means that every movement is dictated by a software program. You create a design file on a computer (using CAD software), send it to the machine, and the CNC controller executes the cuts with a level of high precision that is simply impossible to achieve manually. This technology allows you to cut eps foam into virtually any shape you can imagine.

The benefits are enormous. A CNC machine can produce intricate 2D profiles and even complex 3D thermocol cutting by using multiple, independently controlled wires. Think of tapered columns or detailed logos. The PLC (Programmable Logic Controller) system ensures that every single product is an exact replica of the last, which is crucial for customers who require tight tolerances. This repeatability minimizes errors and material waste. Furthermore, a CNC 3D cutting machine opens the door to high-margin projects that an automatic cutter could never handle. It turns your operation from a simple sheet producer into a custom fabrication specialist. For companies looking to innovate and lead, a high-performance CNC EPS cutting machine is an essential tool.

What Factors Influence the Price of an Industrial Thermocol Cutting Machine?

"What’s the price?" This is always one of the first questions I hear. The truth is, the price of an industrial thermocol cutting machine can vary dramatically. It’s like asking the price of a car—it depends on what you need it to do. As a buyer, your goal is to find the best value, balancing cost with performance and reliability. I always tell my customers that the purchase price is only one part of the equation; the total cost of ownership is what really matters.

Several key factors determine the final price of the machine:

- Automation Level: A fully automatic CNC machine with multiple cutting axes will cost significantly more than a basic manual or semi-automatic machine.

- Size and Capacity: The maximum size of the EPS block the cutting machine can handle directly impacts its cost. A larger machine requires a more robust frame and more powerful motors.

- Build Quality: The quality of the components—the steel frame, the electronics, the motors—plays a huge role. A cheaper machine might save you money upfront, but if it breaks down frequently, the lost production will cost you far more.

- Supplier and Warranty: A reputable supplier who offers a solid warranty, training, and after-sales support will likely have a higher initial price. However, this support is invaluable and a critical consideration for any serious business. This is a major concern for buyers, and a good supplier understands its importance.

Ultimately, you are not just buying a piece of equipment; you are investing in your production capability. A reliable machine from a trusted supplier is an asset that pays for itself.

How Do You Integrate a Block Cutting Machine into a Full EPS Production Line?

For maximum efficiency, a thermocol cutting machine should not operate in isolation. It should be an integrated part of a complete EPS production line. I’ve designed and overseen the installation of many such lines in factories around the world. A seamless workflow is what separates a good operation from a great one. The process typically starts with an EPS block moulding machine, which creates the large, raw blocks of thermocol.

From there, an automatic conveyor system, which we can call a transfer line, moves the freshly cured eps block to the block cutting machine. The first stage is often a squaring machine that trims all sides of the block to ensure it’s perfectly rectangular. Then, the block moves into the main cutting machine, which slices it into sheets of the desired thickness. These sheets can then be automatically stacked, packed, and prepared for shipping. When the entire process is connected, you minimize manual handling, reduce the risk of damage, and dramatically increase throughput.

This is the power of a complete automated system. A fully integrated complete automated EPS cutting line transforms your factory‘s workflow. The entire operation, from raw block to finished product, is streamlined. It reduces labor costs, improves safety, and gives you a consistent, predictable output. This level of automation is the future of efficient EPS foam manufacturing.

What are the Key Features to Look for in a High-Quality Thermocol Sheet Cutting Machine?

When you’re evaluating a specific thermocol sheet cutting machine, you need to look beyond the brochure and examine the engineering. From my experience on the factory floor, I can tell you that small details in the design make a big difference in day-to-day operation. When a potential customer asks for my advice on a cutting machine, I tell them to check these critical features for any quality thermocol cutting machine.

Here is a checklist of what to look for in a new machine:

- Robust Frame: The machine frame should be made of heavy-gauge, welded steel to prevent vibration. A flimsy frame will lead to inaccurate cuts, especially at high speeds.

- High-Quality Cutting Wires: The wires should be from a reputable supplier and made of a durable nickel-chromium alloy that can withstand constant heating and tension without breaking.

- Automatic Wire Tensioning: The best machines have a pneumatic or spring-loaded system that keeps the wires perfectly taut, even as they expand with heat. This is crucial for maintaining cutting accuracy.

- User-Friendly Control Panel: Look for an intuitive interface, preferably a touchscreen PLC system, that makes it easy to set cutting parameters and troubleshoot errors.

- Safety Features: Ensure the machine has emergency stop buttons, safety guards around the cutting area, and wire-break detection systems. Safety should never be a compromise.

- Efficient Power Consumption: Ask about the machine’s energy usage. An efficient transformer and control system can save you a significant amount on electricity bills over the life of the equipment. This is a key requirement for modern manufacturing.

How Can You Ensure Safety and Efficiency When Operating Your Machinery?

Owning a great machine is only half the battle. Operating it safely and efficiently is what truly drives your success. Efficiency isn’t just about cutting fast; it’s about minimizing downtime, reducing waste, and ensuring your team is safe. The best-built machinery can become a liability in the hands of an untrained operator.

First and foremost is training. Every operator should be thoroughly trained on the machine’s functions, safety protocols, and basic maintenance procedures. They need to understand how to properly set up a job, change wires, and, most importantly, how to react in an emergency. Second, a consistent maintenance schedule is non-negotiable. This includes regularly cleaning the machine, checking wire tension, and inspecting electrical components. A well-maintained piece of equipment is a reliable piece of equipment.

Finally, think about your overall workflow. Keep the area around the machinery clean and organized. Have a clear system for staging the EPS blocks and removing the finished sheets. Energy efficiency is also a key part of operational efficiency. Powering down the machine during long idle periods and ensuring the heating elements are working correctly can help control your operational costs. A safe and efficient operation is a profitable one.

What’s the Difference Between a Laser Cutter and a Hot Wire Foam Cutter?

Occasionally, clients ask me about using a laser cutting machine for thermocol. While laser technology is fantastic for many materials like acrylic and wood, it is generally not the right tool for cutting EPS foam. A hot wire foam cutter is superior for this specific application for several important reasons.

The primary issue with using a laser on thermocol is the fumes. The intense heat of the laser beam vaporizes the polystyrene, which can release hazardous fumes that require specialized and expensive ventilation and filtration systems. A hot wire, on the other hand, simply melts the foam, which produces far fewer emissions. Additionally, the cost of a large-format laser machine capable of cutting through a thick EPS foam block is significantly higher than that of an equivalent hot wire machine. The hot wire foam cutter is also much faster for cutting thick materials. A laser beam loses focus and power as it cuts deeper, whereas a hot wire maintains its effectiveness through the entire thickness of the block. For industrial thermocol cutting, the hot wire machine remains the undisputed champion of cost, speed, and safety.

How Do You Choose a Professional and Reliable Supplier for Your EPS Machinery?

Choosing your supplier is perhaps the most critical decision you will make. This is where you avoid the pain points that so many buyers complain about: poor communication, delivery delays, and non-existent after-sales service. A great product from a bad supplier can quickly become a nightmare. As a manufacturer and supplier myself, I’ve built my business on being the partner our clients can trust.

Look for a supplier who is a genuine professional manufacturer, not just a trading company or agent. A true factory has deep technical knowledge of its own machinery. They can provide better support, have spare parts readily available, and can even offer customization. Ask your potential supplier tough questions. What does their after-sales support look like? Do they offer installation and training? What is their warranty policy? Can you speak to some of their existing customers? A confident and reliable supplier will be happy to answer these questions.

Don’t let the price be your only guide. A slightly cheaper machine from an unknown supplier with a questionable support structure is a huge risk. Look for a long-term partner. A great supplier wants to see your business succeed because your success is also their success. They provide a quality product, fair pricing, and stand behind their machinery with excellent service. When you are evaluating your options, remember that you are not just buying a machine; you are entering into a relationship. Choose a professional EPS machine manufacturer who is committed to providing not just a product, but a complete solution.

Key Takeaways for Your Thermocol Cutting Machine Investment

Investing in a new thermocol cutting machine is a major step. By focusing on the right features and choosing the right partner, you can ensure it’s a profitable one.

- Know Your Needs: Decide whether a manual, automatic, or CNC machine best fits your production requirements for cutting thermocol.

- Focus on Quality: A robust frame, high-quality wires, and reliable electronics are more important than the lowest initial price.

- CNC for Versatility: For high precision and the ability to cut complex shapes, a CNC machine is the superior choice and a worthwhile investment.

- Think in Systems: For the best efficiency, integrate your cutting machine into a complete production line, from block moulding to finished product.

- Choose Your Supplier Wisely: Partner with a reputable manufacturer who offers a solid warranty, transparent communication, and excellent after-sales support. This is the most crucial step.

Post time: 11-05-2025