Imagine a material that is 98% air yet strong enough to insulate skyscrapers and protect the most fragile electronics during shipping. That is the reality of Expanded Polystyrene (EPS), often referred to simply as styrofoam or thermocol. However, the magic doesn’t happen in the material itself; it happens in the machine. For a manufacturer looking to dominate the market, understanding the synergy between the thermocol block moulding machine and the foam cutting machine is the difference between profit and loss. This article delves into the mechanics, efficiency, and selection strategies for these critical pieces of equipment, ensuring you get the best product out of every thermocol block.

What is a Thermocol Block Moulding Machine and How Does It Work?

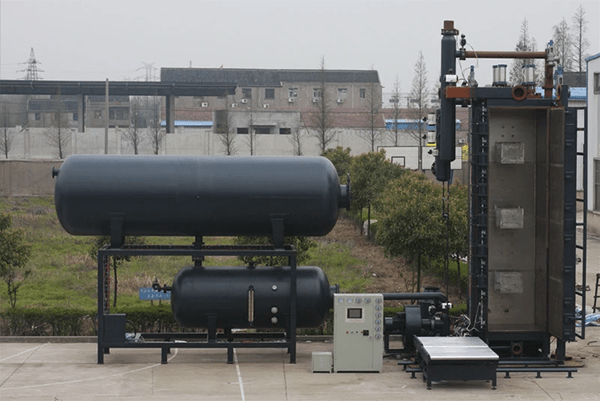

The journey of every EPS product begins with the thermocol block moulding machine. This is the heart of any EPS factory. Before we can think about shapes or sheets, we must create the canvas: the eps foam block. The process is a fascinating display of engineering. Raw EPS beads, which have been pre-expanded, are fed into the moulding machine.

Inside the machine, steam is the primary driver. The beads are subjected to heat and pressure, causing them to expand further and fuse together within the mold cavity. A high-quality block moulding machine ensures consistent density throughout the block. In my experience manufacturing these machines, the cooling phase is just as critical as the heating phase. The machine must use a vacuum system to cool the block rapidly to stabilize it. If the cooling is inefficient, the thermocol block might warp or retain too much moisture, making it a nightmare for the cutting machines later on.

Modern machinery focuses heavily on energy saving. Old models were steam hogs, wasting massive amounts of energy. Today, a professional eps block machine utilizes precise steam valves and insulation to minimize waste. This efficiency is a strict requirement for any factory aiming to stay competitive in the global market.

Why is the EPS Foam Block the Foundation of the Industry?

The eps foam block is the universal currency of the EPS world. Whether you are making insulation panels for construction or decorative cornices, it all starts here. The thermocol block allows for mass production. Instead of molding individual sheets, which would be incredibly slow, we mold massive blocks—often 6 meters long—and then slice them down.

The quality of the block dictates the quality of the final product. If your thermocol block machine produces blocks with uneven density—hard in the corners but soft in the center—your foam cutting machine will struggle. The wires will drag, creating rough surfaces. Therefore, investing in a robust eps thermocol block molder is not just about capacity; it is about providing a stable foundation for the entire production line.

How Do Automatic EPS Cutting Machines Transform Production?

Once the block is cured and dried, it moves to the cutting machines. This is where precision meets speed. An automatic eps cutting machine is designed to take that massive block and slice it into sheets or specific profiles with high efficiency.

The transition from manual to automatic cutting has revolutionized the industry. In the past, operators had to manually adjust wires, leading to human error and wasted material. Now, a modern foam block cutting machine uses a computer control system. You input the dimensions, and the machine adjusts the wires automatically. This device can handle horizontal, vertical, and cross-cutting simultaneously.

For a business owner like Mark, whom I often speak with at exhibitions, the speed of the cutting machine eps is a major selling point. When you have a continuous flow of blocks coming from the molder, you cannot afford a bottleneck at the cutting stage. High-speed cutting machines ensure that the production flow remains uninterrupted.

Hot Wire EPS Foam Technology: Precision Meets Efficiency

The core technology behind most eps foam cutting is the hot wire. It sounds simple, but the engineering behind a hot wire eps foam cutter is sophisticated. The wire, usually made of a nickel-chromium alloy, is heated to a specific temperature. It doesn’t physically "saw" the foam; it vaporizes it just ahead of the wire.

This results in a sealed, smooth surface that mechanical saws cannot replicate. However, the tension and temperature control must be perfect. If the wire is too hot, the cut is too wide (large kerf). If it’s too cold, the wire drags and breaks. A professional foam cutting machine includes transformers and tensioners that maintain these parameters in real-time.

Furthermore, high precision is achieved through the frame stability. A rigid frame prevents vibration. When I design a machine, I ensure the structure is heavy enough to dampen any movement, ensuring that the sheet or panel produced is perfectly flat and consistent.

CNC Foam Cutting Machine: The Solution for Complex Shapes

While standard cutting machines are great for sheets, what happens when you need a 3D shape or a complex architectural profile? This is where the CNC (Computer Numerical Control) foam cutting machine comes into play.

A CNC eps machine takes a digital design file and translates it into movement. It can guide the cutting wire through intricate paths that would be impossible for a human hand. This equipment is essential for producing eps shape products like column molds, movie props, or custom packaging inserts.

The cnc aspect adds a layer of versatility to your factory. You are no longer limited to straight lines. You can offer thermocol plate designs or artistic sculptures. For a manufacturer looking to expand their product catalog, a CNC eps foam cutting machine is the logical next step.

Integrating an EPS Block Machine into a Continuous Production Line

Efficiency is not just about one fast machine; it’s about how the machines talk to each other. In a modern production line, the eps block machine and the cutting machines are linked via an automatic conveyor system.

This setup creates a machine continuous workflow. The block is ejected from the moulding machine, weighed, placed on a storage rack for curing, and then automatically fed into the eps cutting machine. This reduces labor costs significantly. There is no need for forklifts to constantly move blocks around, reducing the risk of damaging the eps foam block.

When setting up a factory, I always advise clients to look at the "flow." The machinery should be arranged to minimize travel distance. A machine thermocol block setup that feeds directly into a cutting line is the gold standard for high-volume manufacturing.

Key Features to Look for in a Professional Machinery Manufacturer

Choosing the right machinery manufacturer is as important as choosing the machine itself. Not all cutting machines are created equal. As a professional in this field, here is what I suggest you look for:

- Steel Quality: The machine frame should be made of high-grade steel to resist corrosion and vibration.

- Component Sourcing: Does the manufacturer use reputable brands for the PLC, motors, and pneumatics? A machine eps foam unit is only as reliable as its weakest component.

- After-Sales Service: EPS machinery requires maintenance. You need a supplier who provides spare parts and technical support.

- Customization: Can the factory adapt the machine to your specific requirement? Perhaps you need a wider cutting bed or a taller vertical cut.

Don’t just look for the best price; look for the best value. A cheap machine that breaks down every week will cost you more in lost production than a premium machine costs upfront.

From Insulation to Packaging: Applications of EPS Styrofoam Blocks

The versatility of the eps thermocol block is why this industry is so resilient. The product coming off your cutting machines has endless applications.

- Construction: This is the biggest market. EPS is used for wall insulation, roof panels, and floor heating systems. The block machine eps must produce high-density foam for these load-bearing applications.

- Packaging: From electronics to fish boxes, eps styrofoam is the king of protection. CNC machines often cut these custom shapes.

- Decoration: Thermocol making for events, weddings, and theater sets relies on the smooth finish provided by hot wire eps foam cutters.

Understanding the end application helps you calibrate your machine. For insulation, density consistency is key. For packaging, the speed of the eps cutting machine is the priority.

Maintenance and Safety for Your EPS Thermocol Equipment

To get the longest life out of your machinery, maintenance is non-negotiable. An eps foam cutting machine involves high voltage and high heat. Safety guards and emergency stops must be functional.

Routine checks should include:

- Wire Tension: Loose wires lead to bad cuts.

- Steam Valves: Leaky valves on the moulding machine waste energy.

- Rail Lubrication: The moving parts of the cutting machines need to glide smoothly to ensure precision.

A well-maintained device not only lasts longer but also produces a better product. In my factory, we emphasize a strict maintenance schedule for every machine styrofoam unit we operate.

How to Balance Price and Quality When Buying EPS Machinery

Finally, let’s talk about the sales aspect. Buyers often come to me asking for the wholesale price. While price is important, you must consider the Return on Investment (ROI).

A high-speed automatic eps cutting machine might cost 20% more than a semi-automatic one, but if it doubles your output, it pays for itself in six months. Similarly, an energy saving thermocol block moulding machine might have a higher price tag, but the savings on steam generation will add up to thousands of dollars a year.

When evaluating a model, look at the cycle time, the energy consumption per block, and the scrap rate of the cutting machines. These operational costs are far more significant than the initial purchase price of the machine.

Summary

The world of EPS manufacturing is driven by the capabilities of the machine. From the massive thermocol block moulding machine that creates the raw material to the precise foam cutting machine that shapes it, every piece of equipment plays a vital role.

- Foundation: The thermocol block moulding machine sets the quality standard for the entire process.

- Precision: Automatic cutting machines ensure consistency and reduce waste.

- Technology: Hot wire eps foam and CNC technologies enable complex shapes and smooth finishes.

- Integration: A continuous production line maximizes efficiency and minimizes labor.

- Value: Choose a professional manufacturer and focus on long-term ROI rather than just the initial price.

By investing in the right machinery, such as our EPS Cutting Machine or a robust EPS Block Moulding Machine, you position your business to lead in the competitive eps market. Whether you are producing insulation sheets or intricate thermocol plate designs, the right machine makes all the difference.

Post time: 01-07-2026