Understanding the thermal properties of your materials is the secret ingredient to running a successful foam factory. If you are like my client Mark Thompson, you know that knowing the melting point of expanded polystyrene isn’t just science trivia; it is the difference between a perfect product and a melted mess. In this article, I will explain the melting point of EPS, how it behaves inside an EPS machine, and how you can use this knowledge to optimize your production line for better insulation and packaging results.

What Exactly is Expanded Polystyrene (EPS) and How is it Made?

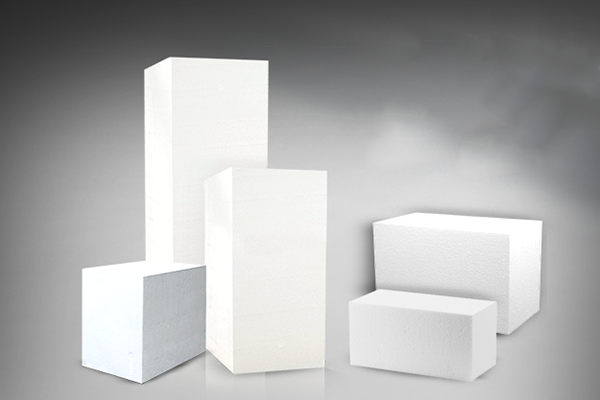

Expanded polystyrene, or EPS, is that lightweight, rigid white foam we see everywhere. But before it becomes a coffee cup or a helmet liner, it starts as small, solid beads. These are solid beads of polystyrene. The magic ingredient inside these beads is a blowing agent, usually a hydrocarbon called pentane.

When we want to make EPS foam, we don’t just melt plastic. We engage in a chemical reaction using heat. The process begins with EPS beads. These beads are tiny and hard. When we apply steam, the pentane gas expands, and the polystyrene softens. This causes the beads to grow to over 40 times their original size. This creates a closed-cell structure.

Most people don’t realize that EPS is 98% air. This is why it is so lightweight. The plastic material only makes up 2% of the volume. As a manufacturer of EPS machinery, I always tell my clients that you are mostly selling air, which is a great business to be in! The closed-cell nature of the beads is what gives EPS its strength and its amazing insulation properties. It traps air, and air is a terrible conductor of heat, which makes EPS an excellent insulator.

What is the Melting Point of Polystyrene and How Does Heat Affect EPS Foam?

Now, let’s talk about the melting point. This is the critical number for setting up your EPS machine. Technically, polystyrene is a thermoplastic. This means it becomes soft when heated and hard when cooled. It doesn’t have a sharp melting point like ice turning into water. Instead, it softens gradually.

The glass transition temperature of polystyrene is around 90°C to 100°C (194°F – 212°F). At this temperature, the solid plastic turns into a rubbery state. This is the sweet spot for molding. However, the actual melting point where it turns into a liquid is much higher, typically around 240°C (464°F).

For EPS foam, we are concerned with the softening point. If you heat EPS above 100°C, it starts to soften and fuse. This is exactly what we want to happen inside the mold. But if you go too high, say closer to the true melting point, the foam structure collapses. The air escapes, and you are left with a hard lump of plastic.

Understanding this temperature range is vital. In an EPS machine, we use steam to reach temperatures just above 100°C. This allows the beads to expand and stick together without melting completely into a liquid. If your steam is too hot, you ruin the product quality. If it is too cool, the beads won’t fuse, and the product will fall apart.

How Does the Manufacturing Process Utilize the Melting Point of EPS?

The manufacturing process of EPS is a dance with temperature. It happens in three main stages, and knowing the melting point helps you control each one.

First is pre-expansion. We use an EPS pre-expander. We feed the raw EPS beads into a chamber with steam. The heat softens the plastic (approaching that glass transition point) and the blowing agent expands. We must be careful here. If we hit the melting point, the beads will collapse.

Second is conditioning or aging. The expanded beads cool down. The air inside cools and contracts, creating a vacuum. Air from the outside rushes in to fill the air voids. This gives the beads their strength.

Third is molding. This is where the EPS shape moulding machine comes in. We put the loose, expanded beads into a mold. We close the mold and inject steam again. This time, we want the beads to soften just enough so they stick to their neighbors. We are flirting with the melting point here. The goal is fusion, not liquefaction.

Once the beads are fused into the shape of the mold, we must cool it down quickly. If we open the mold while the EPS is still near its softening temperature, the part will deform. We use water or vacuum cooling to bring the temperature down, solidifying the plastic so it keeps its shape.

EPS vs. XPS: What is the Difference Between Expanded and Extruded Polystyrene?

I often get asked about the difference between EPS and XPS. Both are made of polystyrene, so they share a similar base melting point, but the manufacturing method is different.

EPS (Expanded Polystyrene) is produced from solid beads that are fused together. Imagine a popcorn ball. You can see the individual beads if you look closely. It has tiny spaces between the beads, although the beads themselves are closed-cell.

XPS (Extruded Polystyrene) is made by extrusion. The polystyrene crystals are melted together with special additives and a blowing agent into a liquid. This liquid is then pushed through a dye (like a pasta maker) to extrude a continuous sheet of foam. This is why it is called extruded polystyrene.

XPS creates a completely uniform closed-cell structure without the gaps found in EPS. This gives XPS slightly higher moisture resistance and compressive strength. However, EPS is generally more cost-effective and flexible in terms of shape. You can mold EPS into complex 3D shapes for packaging, whereas XPS is mostly sold as flat boards. Both materials rely on managing the melting point of the plastic, but XPS takes the material past the melting point to mix it, while EPS keeps it just soft enough to expand.

What are the Main Benefits of EPS Foam for Industrial Applications?

There are many benefits of EPS that make it a favorite for business owners like Mark.

- Lightweight: Because it is 98% air, it adds almost no weight to packages. This reduces transportation costs significantly.

- Shock Absorption: The closed-cell structure acts like millions of tiny airbags. It is excellent for protecting fragile electronics.

- Thermal Insulation: It has a very low heat transfer rate. This makes it perfect for keeping things cold or hot.

- Moisture Resistance: While not waterproof, EPS does not absorb water easily. It resists mold and rot.

- Chemical Resistance: EPS is resistant to many chemicals, although it can be damaged by solvents.

- Cost-Effective: Compared to other foams like EPP (Expanded Polypropylene) or EPE foam is also an option, EPS is usually the most affordable.

When you combine these factors, you see why EPS foam typically dominates the market. It is the smart choice for businesses looking to balance performance and cost.

Why is EPS Insulation Considered One of the Best Thermal Solutions?

EPS insulation is a powerhouse in the construction industry. Because of its insulating properties, it is widely used to insulate walls, roofs, and foundations.

The magic lies in the stagnant air. Air is a poor conductor of heat. By trapping air in billions of tiny bubbles, EPS stops heat from moving through it. In the summer, it keeps the heat out. In the winter, it keeps the heat in. This makes buildings energy-efficient.

EPS insulation comes in various densities. High-density EPS has a higher R-value (resistance to heat flow) and is stronger. It can even be used under concrete slabs. Unlike fiberglass, EPS does not sag or settle over time. Its thermal insulation properties remain stable for the life of the building.

Another advantage is that EPS can be molded with flame retardants to meet fire safety codes. While polystyrene burns if exposed to a high enough flame (well above its melting point), the additive causes it to self-extinguish once the flame source is removed.

What are the Key Applications of EPS Products in Today’s Market?

The number of applications for EPS is staggering. Because we can control the density and shape using a shape molding machine, we can use it almost everywhere.

- Packaging: This is the most visible use. EPS packaging protects TVs, computers, and appliances. It is also used for food containers because it keeps food fresh.

- Construction: Beyond insulation material, EPS is used for architectural moldings (like fake columns), geofoam for road construction (to reduce load on soil), and insulated concrete forms (ICF).

- Automotive: EPS is used inside car bumpers and doors to absorb impact energy.

- Horticulture: Seedling trays made of EPS keep soil warm.

- Medical: EPS coolers are essential for transporting vaccines and organs within the distribution chain because they maintain a stable temperature range.

Whether you are shipping fresh fish or building a skyscraper, EPS products are likely involved.

How Does an EPS Shape Moulding Machine Create Complex Designs?

This is my favorite part. The EPS shape moulding machine is the artist of the factory. Unlike a block molding machine that just makes large blocks, a shape molding machine creates specific, detailed items.

Here is how it works:

- Mold Design: You create a metal mold (usually aluminum) in the negative shape of your product.

- Filling: The machine fills the mold cavity with pre-expanded EPS beads.

- Steaming: Steam is injected into the mold. This raises the temperature to the softening point (remember, near that 90°C mark, but not the full melting point).

- Fusion: The beads expand further and fuse together, taking the exact shape of the mold.

- Cooling: The machine cools the mold to set the plastic.

- Ejection: The mold opens, and the finished part pops out.

This process allows for various shapes and intricate details. You can mold logos, screw holes, and complex curves directly into the foam. The melting point plays a crucial role here. If the machine heats the beads too much (near the liquid melting point), the part will shrink and warp. If it’s too cool, the surface will look rough. A good machine controls this temperature precisely.

Is EPS Recyclable and Environmentally Friendly?

There is a misconception that EPS is bad for the environment. The truth is, EPS is recyclable. Because it is a thermoplastic, we can melt it down and use it again.

We use an EPS recycling machine to crush the waste foam and melt it. Since the melting point is relatively low (around 240°C to fully liquefy), it doesn’t take much energy to melt it down. The air escapes, and we are left with a dense plastic ingot.

This recycled material can be used to make picture frames, park benches, and even new insulation products. Recycling EPS keeps it out of landfills and reduces the need for new oil to make virgin plastic.

Also, EPS consists of 98% air. It does not contain CFCs or HCFCs that damage the ozone layer. By being so lightweight, it minimize fuel consumption during transport compared to heavier packaging materials. So, in many ways, EPS is an environmentally responsible choice when managed correctly.

How Can Understanding Melting Points Improve Your Product Quality?

For a factory owner, knowledge is power. Understanding the melting point and thermal behavior of EPS allows you to troubleshoot issues.

- Surface Defects: If your product looks melted or shiny, your steam temperature is likely too high, approaching the liquid melting point.

- Poor Fusion: If the beads fall apart, you aren’t reaching the softening temperature. You need more heat or time.

- Shrinkage: If the part shrinks after coming out of the mold, you might be ejecting it while it is still too hot (above the glass transition temperature). You need a longer cooling cycle.

By respecting the melting point, you can tune your EPS machine for peak performance. You ensure that every bead is used effectively, creating a product that is strong, accurate, and profitable.

Summary

- EPS is a lightweight, closed-cell foam made from polystyrene beads and a pentane foaming agent.

- The melting point of polystyrene is around 240°C, but EPS is molded at its softening point near 90°C-100°C.

- EPS machines use steam to expand and fuse beads without reaching the full melting point.

- EPS differs from XPS in its manufacturing (molding vs. extrusion) and structure.

- Key benefits include thermal insulation, shock absorption, and being lightweight.

- EPS insulation is energy-efficient and widely used in construction.

- The EPS shape moulding machine allows for complex designs by controlling temperature and pressure within a mold.

- EPS is recyclable and can be melted down to create new plastic products.

- Correctly managing processing temperatures relative to the melting point ensures high product quality and minimizes waste.

- YouLi provides advanced machinery like the EPS Shape Moulding Machine to help you master this process.

Post time: 12-31-2025