Expanded Polystyrene, or EPS, is one of the most versatile materials in modern industry. You know it as the protective packaging for a new appliance, the lightweight take-out container for your lunch, or the efficient insulation in building walls. But this utility comes with a question I hear often from my clients: why is Styrofoam so hard to recycle? As someone who has spent over two decades manufacturing the machinery that creates and recycles this foam, I want to offer you an insider’s perspective. This article will demystify the challenges of polystyrene recycling, explore the cutting-edge solutions available, and show you why investing in the right technology is not just good for the planet, but great for your bottom line. It’s a complex topic, but the solutions are more accessible than you might think.

What Exactly Is Expanded Polystyrene (EPS) and Why Is It Everywhere?

Expanded Polystyrene, commonly known by the trademarked name Styrofoam, is a rigid cellular plastic made from styrene monomers. The magic of EPS is in its manufacturing process. Tiny solid polystyrene beads are expanded with steam, causing them to puff up like popcorn. These expanded beads, which are now about 98% air, are then molded into large blocks or custom shapes. This process creates a material that is incredibly lightweight, yet strong and durable, with excellent insulation and shock-absorbing properties. It’s a marvel of material science.

This unique combination of features is why EPS has become ubiquitous. In the packaging industry, it’s the gold standard for protecting fragile electronics, appliances, and medical supplies during shipping. Its low weight reduces transportation costs, and its ability to be molded into any shape provides a perfect, secure fit. In construction, EPS foam is a go-to material for thermal and acoustic insulation in walls, roofs, and floors, contributing significantly to energy efficiency. And of course, in the food service industry, its insulating properties keep hot food hot and cold food cold, making it a popular choice for a disposable coffee cup or take-out container. The versatility of this plastic is undeniable.

Is Polystyrene Plastic Actually Recyclable?

This is the big question, and the answer is an emphatic yes. Technically, EPS is recyclable. The material itself, the polymer known as polystyrene, can be melted down and reformed into new products. The challenge isn’t with the material’s inherent properties but with the logistics and economics of the recycle process. When we say something is "hard to recycle," we are usually talking about the practical barriers that prevent it from being widely processed by municipal recycling facilities.

The common misconception that EPS is not recyclable stems from its frequent exclusion from curbside recycling bin programs. However, there is a growing network of specialized facilities and drop-off locations with the capability to recycle this specific type of plastic. The recycled EPS material, often called "regrind," can be used to manufacture new foam products or densified into ingots. These ingots are then sold as a commodity to create products like picture frames, park benches, and architectural molding. So, while it’s not as simple as tossing a cardboard box into the bin, the pathways to recycle polystyrene do exist and are becoming more robust. The key is separating the technical possibility from the current public infrastructure limitations.

Why Don’t Most Curbside Recycling Programs Accept EPS Foam?

The primary reason EPS is rejected by most curbside recycling programs is its physical nature. As I mentioned, EPS foam is 98% air. This makes it extremely lightweight but also incredibly bulky. A truck full of uncompressed EPS foam contains very little actual plastic material by weight. For municipal waste management programs that operate on tight budgets, collecting and transporting this bulky material is not economically viable. The cost of transportation far outweighs the value of the recovered polystyrene. It’s simply expensive to process for the small amount of raw material you get back.

Furthermore, standard municipal sorting facilities (often called Material Recovery Facilities or MRFs) are designed to separate heavier materials like glass, metal, and other plastics like PE and PP. Lightweight EPS foam often gets mis-sorted. It can fly off conveyor belts, get mistaken for paper, or break into small pieces that contaminate other recycling streams, preventing other materials from being properly recycled. This makes it hard to recycle the entire batch of materials. Because of these logistical and mechanical challenges, many local governments have decided to exclude it from their programs to maintain the efficiency and cleanliness of their overall recycling operations. The focus is on materials that are easier and more profitable to recycle.

How Does Contamination Make EPS So Difficult to Recycle?

Contamination is the arch-nemesis of all recycling, but it poses a particularly severe problem for polystyrene recycling. The most common source of contamination for post-consumer EPS is leftover food residue. Think of a greasy hamburger container or a coffee-stained cup. This food packaging residue cannot be easily washed off the porous surface of the foam. When this contaminated plastic is processed, the food waste can ruin the entire batch of recycled material, making it unusable. The high level of contamination makes it a significant barrier for any recycler.

Beyond food waste, other contaminants like tape, labels, and dirt also present a major issue. A recycling center requires a pure stream of material to produce high-quality recycled plastics. Workers at a facility are often unable to separate these small bits of tape and paper from the foam efficiently. This contamination not only lowers the quality of the final product but can also damage the processing machinery. For a successful recycle operation, the EPS feedstock must be as clean as possible, which is difficult to ensure when collecting it from millions of individual households. This is why many successful polystyrene recycling programs focus on industrial or commercial sources where the material is cleaner and more uniform.

What Are the Main Economic Hurdles to Polystyrene Recycling?

The economic viability of recycling any material is a simple calculation: does the cost of collection, sorting, and processing exceed the market value of the resulting raw material? For EPS, this calculation is often unfavorable. The primary economic hurdle, as we’ve touched on, is its low density. Transporting a truckload of air is not cheap. This is a major reason why polystyrene is so hard to manage profitably through traditional collection models. Unless there is a facility that accepts it nearby, the shipping costs can be prohibitive.

To overcome this, the industry developed densification technology. Machines like compactors and densifiers can reduce the volume of EPS foam by up to 90:1. This makes transportation economically feasible. However, this machinery represents a significant capital investment. A business or recycling center must be able to collect enough clean EPS to justify the cost of the equipment. Furthermore, the market price for recycled polystyrene can fluctuate. When the price of virgin plastic is low, it can be cheaper for manufacturers to buy new material rather than recycled plastics, reducing the demand and depressing the price for the material you worked so hard to recycle. This market dynamic presents a constant challenge to the profitability of the EPS recycle industry.

Can You Recycle EPS in a Different Way? Exploring Chemical Recycling

While mechanical recycling (shredding, melting, and reforming) is the most common method, an exciting and advanced alternative is gaining traction: chemical recycling. This process, also known as advanced recycling or feedstock recycling, uses heat and chemical processes to break the polystyrene polymer back down into its original building block: styrene monomer. This resulting liquid styrene is indistinguishable from virgin styrene produced from petroleum.

This is a game-changer for several reasons. First, chemical recycling can handle a wider range of contaminated plastic waste, including EPS with food residue or other impurities that would be problematic for mechanical recycling. The purification process effectively removes these contaminants. Second, the output is a high-quality raw material that can be used to make new food-grade packaging, creating a true closed-loop system. This overcomes the "downcycling" issue where a plastic is recycled into a lower-quality product. While the technology is still maturing and requires significant energy, it holds immense promise for transforming how we recycle materials that are traditionally hard to recycle, like single-use foam products.

Here’s a simple breakdown of the two main methods:

| Feature | Mechanical Recycling | Chemical Recycling |

|---|---|---|

| Process | Shreds, melts, and reforms the plastic. | Breaks polymer down into its original monomer (styrene). |

| Input Quality | Requires very clean, sorted EPS. | Can handle more contamination. |

| Output Quality | Often "downcycled" into non-food grade products. | Creates virgin-quality styrene for new food-grade products. |

| Maturity | Well-established and widely used technology. | Emerging technology, higher energy and capital costs. |

| Best For | Clean, industrial post-production scrap. | Mixed or contaminated post-consumer plastic waste. |

What is the Role of Technology in Making EPS Recycling Feasible?

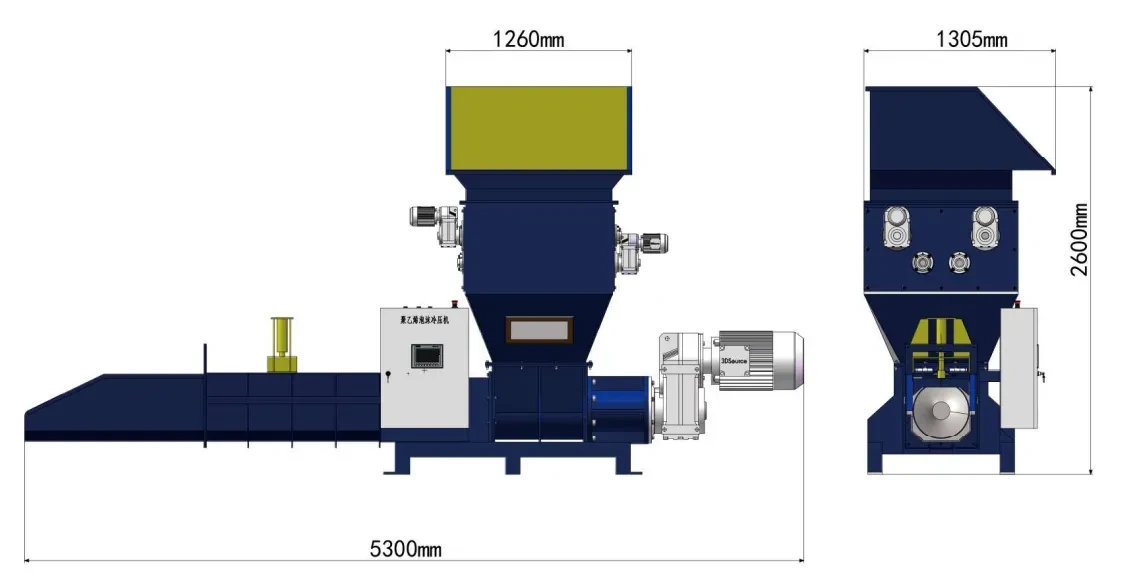

As a manufacturer, this is where I get excited. Technology is the bridge that closes the gap between "technically recyclable" and "practically recycled." For business owners like my client Mark in the USA, investing in the right machinery is the single most effective step toward sustainable and profitable EPS management. The first and most crucial pieces of equipment are compactors and densifiers. By dramatically reducing the volume of foam scrap, these machines slash transportation costs and turn a bulky waste problem into a valuable, shippable commodity. An efficient EPS Compactor Machine is the cornerstone of any serious polystyrene recycling program.

Beyond compaction, a complete recycling line can offer even greater value. For manufacturers, integrating a system that can process production scrap is a massive efficiency gain. A comprehensive EPS Recycling Machine that includes a Crusher, De-duster, and Dust compactor can take leftover material, grind it into "regrind," clean it, and feed it right back into the production process. This reduces waste disposal costs and lowers the need to purchase virgin raw materials. Automation plays a huge role here as well. Systems like an Automatic EPS Block Conveyor can streamline the movement of blocks and scrap, minimizing labor and maximizing throughput. The right technology transforms plastic waste from a liability on your balance sheet into an asset.

How Can Businesses Improve Their In-House EPS Recycle Rates?

For any company that produces or receives large quantities of EPS—whether you’re a manufacturer, a retailer, or a logistics firm—the most impactful changes you can make happen within your own four walls. Waiting for municipal programs to catch up is not a proactive strategy. The first step is source separation. Designate a specific, clean, and dry area for collecting all EPS scrap and packaging. This prevents it from getting mixed with other waste and contaminated. Train your staff on what can and cannot be placed in the EPS collection bins—no plastic bags, no coffee cups, no tape.

The second, and most transformative, step is investing in on-site volume reduction. As discussed, a cold compactor or a thermal densifier is essential. This immediately solves the storage and transport problems. A pile of bulky foam that would fill a dumpster can be reduced to a few dense, stackable blocks. These blocks are far more attractive to a recycler and command a higher price. By creating a clean, dense, and uniform commodity, you become a reliable supplier in the recycling chain, not just another company trying to offload waste. This proactive approach to sustainability gives you control over your waste stream and can even create a new revenue stream for your business. You can recycle your own material and become part of the solution.

Are There Alternatives to Single-Use Polystyrene Packaging?

The conversation around sustainability inevitably includes a discussion of alternatives. Materials like molded pulp, mushroom packaging, and cornstarch-based foams are emerging as potential replacements for some applications. For certain uses, especially simple food packaging where insulation is less critical, materials like cardboard or other plastics (polypropylene, for example) can be effective. These materials often have more established recycling streams, making them an easier choice for consumers and municipalities. The drive to reduce single-use items is a powerful force in the market.

However, it’s crucial to evaluate these alternatives based on a full life-cycle analysis. Some alternatives require more energy to produce, are heavier (increasing transport emissions), or may not offer the same level of product protection, potentially leading to more damaged goods and waste. The truth is, for high-performance applications requiring superior insulation, shock absorption, and low weight, EPS remains one of the most effective materials available. The challenge isn’t necessarily to replace it everywhere, but to build a robust system to reuse and recycle it effectively. The goal is to move towards a circular economy where the polystyrene is not seen as disposable waste, but as a valuable resource to be captured and remade. Even a simple peanut used in packing peanuts can be part of this cycle.

What Does the Future of Polystyrene Recycling Look Like?

I am incredibly optimistic about the future of polystyrene recycling. The narrative that "styrofoam is so hard" to recycle is being rewritten by technology and innovation. We are seeing a convergence of factors that will make EPS recycling more widespread and efficient. Public awareness and consumer demand for sustainable solutions are putting pressure on brands and governments to act. This is driving investment in new collection infrastructures and advanced recycling technologies like the chemical recycling processes we discussed. The problem of essentially non-biodegradable waste in a landfill is a powerful motivator.

From my perspective as a machinery manufacturer, I see the technology advancing rapidly. Machines are becoming more efficient, more automated, and more accessible to a wider range of businesses. We are designing complete systems, from Best Sale EPS Cutting Lines that minimize waste from the very start of production to sophisticated recycling plants that can close the loop entirely. The future is a hybrid model where clean, industrial scrap is mechanically recycled on-site, and more challenging post-consumer waste is handled by advanced chemical recycling facilities. Polystyrene is not a "bad" material; we’ve just been bad at managing its end-of-life. That is changing, and for businesses ready to embrace the change, the opportunity is immense. The journey to recycle this valuable plastic is well underway.

Key Takeaways to Remember

- EPS is 100% Recyclable: The material itself can be recycled. The challenges are economic and logistical, not technical.

- Density is the Main Problem: EPS foam’s light, bulky nature makes it expensive to collect and transport, which is why it’s often excluded from curbside programs.

- Contamination is a Major Barrier: Food residue, tape, and labels on post-consumer foam can ruin batches of recycled material, making clean source separation critical.

- Technology is the Solution: On-site machinery like compactors and densifiers solves the density problem by reducing volume, making recycling profitable and practical for businesses.

- Two Paths to Recycle: Mechanical recycling is ideal for clean industrial scrap, while emerging chemical recycling technology offers a powerful solution for contaminated post-consumer waste.

- Proactive Management is Key: Businesses can achieve high recycling rates and even create revenue by implementing in-house collection programs and investing in the right equipment.

Post time: 08-05-2025