Hello, I’m Allen. For years, my world has been the hum of machinery and the smell of newly manufactured equipment. As a manufacturer of EPS and EPP foam machinery, I’ve spent countless hours on the factory floor and at international exhibitions. I’ve spoken with hundreds of business owners like Mark Thompson from the USA—sharp, decisive leaders who need to get the job done right. They’re looking for more than just a machine; they need a reliable foam cutter that performs consistently and a partner they can trust. This guide is born from those conversations. We’re going to dive deep into the world of CNC routing and milling machine technology for foam, helping you make informed decisions to elevate your manufacturing process.

What is the Difference Between a CNC Foam Mill and a Router?

When you start exploring the world of CNC foam cutting, you’ll quickly encounter the terms "mill" and "router." While they are often used interchangeably in discussions, especially on a forum, there are some key engineering differences. A traditional milling machine is typically built for heavy-duty work on metals like steel and aluminum. It’s incredibly rigid, often has a smaller work area, and is designed for extreme precision. A CNC router, on the other hand, is usually a gantry-style machine where the spindle moves over the material along an X and Y axis. They are designed for high-speed work on larger sheets of softer materials like wood, plastic, and, most importantly for us, foam.

For the purpose of cutting foam, a CNC router is almost always the more appropriate and cost-effective machine. Its large work area is perfect for handling standard foam sheet sizes, and its high-speed capabilities are exactly what you need for clean, efficient cuts. So, while you might hear someone refer to their foam cutting setup as a "mill," it’s highly likely they are using a CNC router. The principles of using a spinning tool to cut foam are the same, but the machine architecture is optimized for the material. When you are looking for a machine for cutting foam, focusing your search on "CNC routers for foam" will yield the most relevant results.

The key takeaway is that for foam fabrication, you need a machine that prioritizes speed and workspace over the raw cutting power needed for metal. The rigidity of the machine is still important to prevent vibration at high speeds, but you don’t need the massive cast-iron frame of a true metalworking mill. This distinction helps guide your investment toward the right kind of equipment for the job.

What Kind of Foam Can You Reliably Cut with a CNC Machine?

The versatility of a CNC machine is one of its greatest strengths. It can handle a vast array of foam types, each with its own unique properties and challenges. Understanding the kind of foam you’re working with is the first step to achieving a perfect cut.

Here’s a look at some common foams used in CNC routing:

- Polyurethane Foam (PU Foam): This is a massive category. It includes everything from rigid, high-density tooling board, which mills beautifully and can be used to create a master mold or prototype, to soft foam used in upholstery and cushions. The hard foam variety allows for incredible detail and a very smooth surface finish, while the soft variety requires an extremely sharp cutter to avoid tearing.

- Expanded Polystyrene (EPS): This is the lightweight, white beaded foam commonly used for packaging, insulation, and large props. It’s very easy to cut, but the right tool is needed to get a clean edge without melting the beads together.

- Extruded Polystyrene (XPS): Often blue or pink, this foam has a finer, more consistent cell structure than EPS. It’s a favorite among model makers and sign builders because it can hold a sharp edge and fine detail when cut with a CNC router.

- Polyethylene (PE) Foam: This is a tougher, more flexible foam often found in case inserts and flotation devices. Cutting it can be a challenge as it’s prone to grabbing the tool. A very sharp, specialized foam cutter is often required.

The key is to match your cutting strategy to the material. A hard foam like tooling board can be treated almost like a soft wood, allowing for aggressive material removal. When you cut a soft foam, however, you need to use a much lighter touch and a razor-sharp tool to slice through the material cleanly rather than pulling at it.

How Do You Choose the Right CNC Machine for Foam Fabrication?

Selecting the right CNC machine is a foundational decision for your business. For a business owner like Mark, it’s about balancing performance, reliability, and cost. When evaluating a CNC foam cutter, you need to look beyond the price tag and consider the features that will directly impact your workflow and product quality. The gantry height, or Z-axis clearance, is one of the most important factors. You need enough vertical space to accommodate thick blocks of foam as well as the length of your cutting tool and holder.

The build of the machine is also critical. While you don’t need the mass of a metal mill, a rigid, well-welded steel frame is essential to minimize vibration during high-speed cutting motion. This stability is key to achieving high accuracy and a good surface finish. The drive system—whether it uses servo motors or stepper motors—will determine the machine’s top speed and precision. For high-volume manufacturing, servo motors are generally preferred for their superior performance.

Finally, consider the work-holding system. One of the best accessories you can invest in is a vacuum table. A good vacuum system holds the entire foam sheet down firmly and evenly, which is the ideal way to prevent light material from shifting during a cut. When looking at options, consider a complete package. A good CNC EPS cutting machine from a reputable manufacturer will be designed with all these factors in mind, providing a reliable platform for your production needs.

What are the Ideal Tools and Cutters for CNC Foam Carving?

The cutter is where the rubber meets the road—or in this case, where the carbide meets the foam. The wrong tool will ruin your project, wasting time and material. For foam cutting, the primary goal is chip evacuation. You need to get the cut material out of the way as quickly as possible to prevent it from melting and gumming up the tool. This is why the best tools for foam have very deep, open flutes.

Here’s a list of popular tool choices for CNC foam cutting:

- Single and Double Flute Up-Cut Spirals: These are the workhorses for foam. The "up-cut" geometry acts like an auger, pulling chips up and out of the cut path. They are excellent for fast material removal and creating deep pockets or a hole.

- Ball Nose End Mills: When you’re doing 3D carving or creating a surface with smooth, organic contours, a ball nose cutter is the right tool. It leaves a rounded bottom profile, perfect for finishing passes.

- Straight Flute Cutters: These are good for plunging and creating flat-bottomed pockets. They are less aggressive than spiral tools but provide a clean cut. Many are made from solid carbide for a long-lasting sharp edge.

- Specialty Foam Cutters: Some manufacturers produce bits specifically designed for foam, often with unique flute geometries or special coatings to prevent material from sticking. A specialized

foam cuttercan make a huge difference, especially with tricky materials like PE foam.

The sharpness of the tool is paramount. A dull cutter will rub and melt the foam instead of shearing it cleanly. Unlike a wood router, where you might be able to get away with a slightly used bit, foam requires a pristine cutting edge for the best results.

Is a Hot Wire Foam Cutter a Better Method for Your Project?

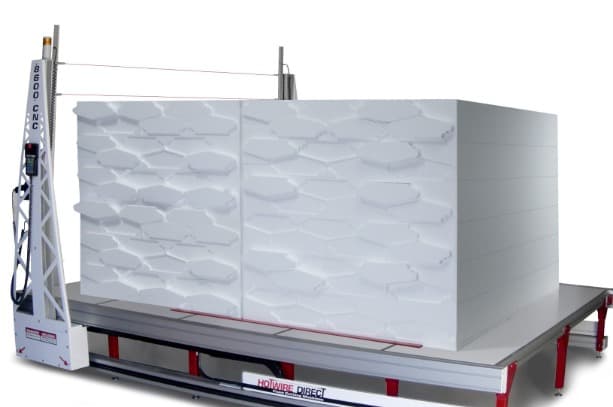

While a CNC router is incredibly versatile, it’s not the only method for cutting foam. For certain applications, a hot wire CNC foam cutter can be a much more efficient choice. This type of machine uses a heated wire under tension to melt its way through the foam. It’s the standard technology for cutting large blocks of polystyrene (EPS and XPS) into sheets or architectural profiles.

The primary advantage of a hot wire cutter is speed and cleanliness when making 2D cuts. It can slice through an entire section of a massive foam block in a single pass, a task that would take a router a very long time. It also produces no dust or chips, only fumes that need to be properly ventilated. The "cut" width, or kerf, is very thin and consistent. However, a hot wire machine has limitations. Since the wire must pass all the way through the material, you cannot create internal pockets, holes, or complex 3D surfaces.

So, which foam cutter is better?

- Choose a CNC Router/Mill if: You need to create complex 3D shapes, engraved details, internal pockets, or work with materials like high-density polyurethane tooling board.

- Choose a Hot Wire Cutter if: Your work primarily involves cutting sheets from large blocks of polystyrene or creating 2D profiles like letters, architectural moldings, or RC airplane wings.

How Do You Dial In the Perfect Speed and Feed Rate to Cut Foam?

Finding the sweet spot for speeds and feeds is one of the most discussed topics in any CNC forum. The "speed" refers to the spindle RPM (revolutions per minute), and the "feed" is how fast the machine moves the cutter through the material. The relationship between these two is critical for a clean cut in foam.

The general rule for foam is: run it fast. A slow feed rate is the enemy of a good finish. When the cutter lingers in one spot for too long, the friction generates heat, which melts the foam. This creates a gummy mess on your tool and a rough, melted edge on your part. You want to move the cutter fast enough that each cutting edge is biting into fresh, cool material. This produces crisp, clean chips instead of a melted disaster.

A good starting point is to set your spindle to a high RPM (e.g., 18,000 RPM or higher) and begin with a fast feed rate. From there, you can make small adjustments. Listen to the sound of the cut. A smooth, quiet hum is what you’re aiming for. If you see melting, your feed rate is too slow for your RPM. If the machine seems to be straining or the tool is chattering, your feed rate might be too aggressive for the depth of cut or the rigidity of your machine. Always do a test cut on a piece of scrap foam before starting a large job.

What’s the Best Way to Secure Foam to Your CNC Machine Bed?

Workholding is a surprisingly significant challenge when using a CNC to cut foam. Because foam is so lightweight, it can easily shift, vibrate, or even be lifted by the up-cut spiral of the cutter. A part that moves even a fraction of a millimeter is a ruined part. You need a method that holds the foam securely across its entire surface without crushing or deforming it.

By far, the most effective solution is a vacuum table. This system uses suction to pull the foam sheet down tightly against the machine’s spoilboard. It provides even, consistent pressure and is the ideal method for high-volume production. It eliminates the need for clamps or adhesives, making setup fast and easy.

If you don’t have a vacuum table, there are other options:

- Adhesives: A light mist of spray adhesive or strips of double-sided tape can be used to stick the foam to a sacrificial board, which is then clamped to the CNC table.

- Jigs and Fixtures: For repetitive jobs, you can create a custom holder or template out of MDF or plywood that the foam piece fits into snugly.

- Screws/Pins: For thick blocks of foam, you can drive screws or pins through the waste areas of the material directly into the spoilboard. Just be absolutely sure that your toolpaths in the software are programmed to avoid them!

How Can You Optimize Your Software and Design File for a Perfect Cut?

The quality of your final product begins on your computer screen. A clean design file and a smart toolpath strategy in your CAM (Computer-Aided Manufacturing) software are essential for a successful cut. Start with a clean vector file, like a DXF file, for 2D profiles, or a watertight 3D model for carving. Any errors in the geometry will be translated into errors by the machine.

When programming your toolpaths, think in stages. Use a larger diameter tool for a "roughing pass" to remove the bulk of the material quickly. This pass can be run at a high speed with a large step-over (the distance the tool moves over between passes). Then, switch to a smaller, often ball-nosed, cutter for a "finishing pass." This pass uses a much smaller step-over to create a smooth final surface. This two-step process is much more efficient than trying to do everything with a single small tool.

Also, pay attention to the details of the toolpath. The entry angle of the cutter into the material can make a difference. Ramping into the cut is gentler on the tool and the foam than plunging straight down. Modern CAM software offers many strategies for optimizing the tool’s path to reduce cutting time and improve the final finish. Taking the time to learn these features will pay off in the quality of your work.

What are the Most Common Challenges When You Cut Foam with a CNC?

Even with the best machine and tool, you can run into issues. From my experience helping clients troubleshoot, here are the most common problems and their solutions when you cut foam:

-

Problem: Melting and Gummy Edges

- Cause: This is almost always a speed and feed issue. Your feed rate is too slow for your spindle RPM, causing excessive heat. A dull tool can also be the culprit.

- Solution: Increase your feed rate. If you can’t, decrease your spindle RPM. And most importantly, ensure your cutter is sharp. A fresh, sharp tool is your best friend.

-

Problem: Fuzzy or Torn Edges (especially on soft foam)

- Cause: The foam is deflecting or tearing instead of being cleanly sliced. This is common with soft foam like the kind used for upholstery. The wrong tool geometry (e.g., too many flutes) can make this worse.

- Solution: Use an extremely sharp single-flute cutter. You can also try a specialized straight knife blade that oscillates or drags, which slices the foam without any rotation. For a very thin sheet (e.g., 10 mm), a drag knife can produce a perfect edge.

-

Problem: The Part Moves During the Cut

- Cause: Your workholding method is failing. The cutting forces are overcoming the friction or adhesive holding the foam in place.

- Solution: Re-evaluate your workholding. If using tape or adhesive, use more. If using a jig, make sure it’s secure. If possible, a vacuum table is the most reliable solution to this problem.

Why Should You Partner with a Professional Manufacturer for Your CNC Machine?

For a business owner, purchasing a CNC foam cutter is a significant investment. The success of that investment often depends as much on the supplier as it does on the machine itself. This is where partnering with a true manufacturer becomes a strategic advantage. A direct relationship avoids the communication breakdowns and support issues that are common pain points when dealing with resellers.

A professional manufacturer has an in-depth understanding of their equipment. They can provide expert advice on the right machine for your specific application, from cutting polyurethane for a mold to shaping polystyrene for packaging. They can provide comprehensive training, reliable technical support, and have a ready supply of spare parts. This is a critical point for buyers like Mark, who know that downtime is incredibly costly.

When you’re ready to invest, look for a partner who is committed to your success. A company that stands behind its products with strong service and support is invaluable. As a professional EPS machine manufacturer, we believe in building long-term relationships. We understand the challenges you face and are dedicated to providing not just a high-quality machine, but a complete and reliable solution for your foam fabrication needs.

Post time: 11-11-2025